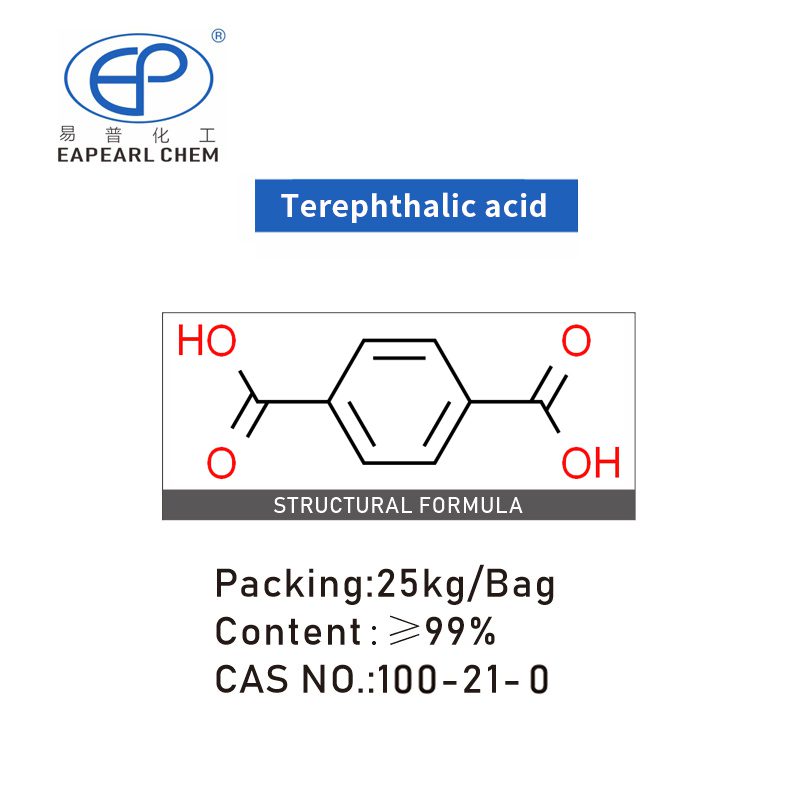

PTA

Terephthalic acid, an organic compound resembling a white powdery substance, claims its prominence as the most abundant dicarboxylic acid. It possesses combustible properties, though with low toxicity, and remains solid at room temperature, defying the conventional melting point upon heating. Solubility reveals itself in alkaline solutions, exhibiting only slight solubility in hot ethanol. However, it remains insoluble in water, ether, glacial acetic acid, and chloroform.

| Product Name: | Terephthalic acid(PTA) |

|---|---|

| CAS No.: | 100-21-0 |

| Purity | ≥99% |

| Packing: | 25kg/Bag |

| HScode: | 29173600 |

We use the latest network security technology to protect your personal information from leakage, and to ensure that you can shop safely and securely.

Share

Description:

Preparation method:

- The low-temperature oxidation process of p-Xylene involves using p-Xylene as a raw material in an acetic acid solvent. Cobalt acetate (or manganese acetate) and bromide are catalysts, while formaldehyde acts as an oxidation accelerator. The reaction occurs at a pressure of 3MPa and temperatures ranging from 100 to 130℃. Air is introduced, enabling one-step low-temperature oxidation. The resulting product is washed with acetic acid and dried to obtain PTA.

- Acetic acid serves as the solvent in the high-temperature oxidation process of p-Xylene. Cobalt acetate and manganese acetate act as catalysts in the presence of tetrabromoethane. The reaction is carried out at a temperature of 220℃ and a pressure ranging from 1.5 to 3MPa. The resulting product is dissolved in water under a pressure of 6.5 to 7.0MPa, forming an aqueous solution of terephthalic acid. Subsequently, a palladium/activated carbon catalyst is employed to hydrogenate and remove trace amounts of p-carboxy benzaldehyde. Finally, PTA is obtained through crystallization, washing, and drying processes.

Synonyms:

Characteristics:

| Molecular Formula | C8H6O4 |

| Molar Mass | 166.13 |

| Density | 1.58 g/cm3 at 25 °C |

| Melting Point | >300 °C (lit.) |

| Boling Point | 214.32°C (rough estimate) |

| Flash Point | 260°C |

| Water Solubility | slightly soluble in water (0,017 g/L at 25°C) |

| Solubility | Slightly soluble in hot ethanol, soluble in alkali, almost insoluble in water, chloroform, ether and acetic acid. |

| Vapor Presure | <0.01 mm Hg ( 20 °C) |

| Appearance | White powder |

| Color | White |

| Exposure Limit | ACGIH: TWA 10 mg/m3 |

| Merck | 149,162 |

| BRN | 1909333 |

| pKa | 3.51(at 25℃) |

| PH | 3.36(1 mM solution);2.79(10 mM solution);2.26(100 mM solution) |

| Storage Condition | Sealed in dry,Room Temperature |

| Stability | Stable. Combustible. Incompatible with strong oxidizing agents. |

| Refractive Index | 1.5100 (estimate) |

| MDL | MFCD00002558 |

| Physical and Chemical Properties | Character White needle-like crystal or powder. The relative density of 1.510g/cm3 soluble in alkali solution, soluble in hot ethanol, insoluble in water, ether, acetic acid and chloroform. |

| PSA | 74.6 |

| XLogP3 | 2 |

Use

FAQ:

You may have a few questions when understanding Terephthalic Acid (PTA). Allow me to provide you with the information you seek in a way that captures your attention. Let’s delve into the fascinating world of PTA:

Q1. What is the significance of Terephthalic Acid (PTA)?

A1. Prepare to be introduced to a remarkable Terephthalic Acid (PTA) substance. This white crystalline solid is pivotal in creating polyethylene terephthalate (PET) resin, polyester fibers, and films. You’ll find it in many industries, such as textiles, packaging, and plastics.

Q2. How does PTA manifest its potential?

A2. PTA truly shines as it forms the backbone of PET resin. This versatile material undergoes further processing to produce an array of end products, including bottles, packaging films, and synthetic fibers. Additionally, it lends itself to manufacturing polyester films, coatings, and engineering plastics.

Q3. What advantages does PTA bring to the table?

A3. PTA boasts a trifecta of advantages that make it an outstanding choice for various applications:

Unparalleled purity: PTA’s purity levels reach unprecedented heights, guaranteeing consistent quality and exceptional performance in downstream applications.

Economical excellence: Selecting PTA as a raw material for PET resin and polyester production proves to be a cost-effective decision, delivering exceptional value for your investment.

Limitless versatility: PTA adapts flawlessly to a wide range of applications, catering to the diverse needs of multiple industries. Its versatility knows no bounds.

Q4. What specifications can one expect from PTA?

A4. While specific details may vary across manufacturers, these are the typical specifications associated with PTA:

Purity: Equal to or greater than 99.9% Moisture: Less than or equal to 0.1% Melting Point: Ranging from 290 to 300°C Color: No more than 10 APHA

Q5. How is PTA packaged for convenience?

A5. Picture PTA in the form of convenient granules or flakes. These remarkable particles are commonly packaged in 25kg or 1,000kg bags. However, should you have specific packaging preferences, we are more than happy to accommodate your requirements.

Q6. What is the shelf life of PTA?

A6. Rest assured, PTA boasts an impressively long shelf life when stored under ideal conditions—a dry and cool environment. To guarantee optimal quality, utilizing the material within one year from the date of manufacture is recommended.

Q7. How should one store PTA?

A7. Providing a nurturing environment for PTA is essential. Optimal storage conditions involve a dry and well-ventilated area shielded from direct sunlight, moisture, and heat sources. Safeguarding the material from air and moisture exposure prevents degradation and ensures its enduring quality.

Q8. How can I acquire PTA for my needs?

A8. Taking the initiative to acquire PTA is a straightforward process. Contacting our dedicated sales team using the provided contact information on our website is the first step. Our team will graciously guide you through the ordering process, extending the necessary assistance at every step.

Q9. What shipping options are available for PTA?

A9. Emphasizing customer satisfaction, we offer various shipping options tailored to your specific needs. Collaborating closely with our logistics team, we consider crucial factors such as destination, order quantity, and urgency to determine the most suitable shipping method for you.

Q10. Are there any precautions to consider when handling PTA?

A10. Absolutely! As with any chemical substance, handling PTA requires caution. When working with PTA, it is advisable to equip yourself with appropriate personal protective equipment (PPE), such as gloves and goggles. For comprehensive handling and safety instructions, please refer to the safety data sheet (SDS) provided with the product.

We hope this engaging FAQ section has addressed your inquiries regarding Terephthalic Acid (PTA). If you seek further clarification or additional information, please don’t hesitate to contact our experienced team. We’re here to assist you every step of the way.

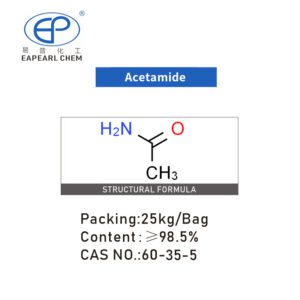

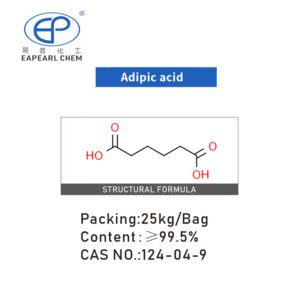

相关产品

Loading Video or Picture: