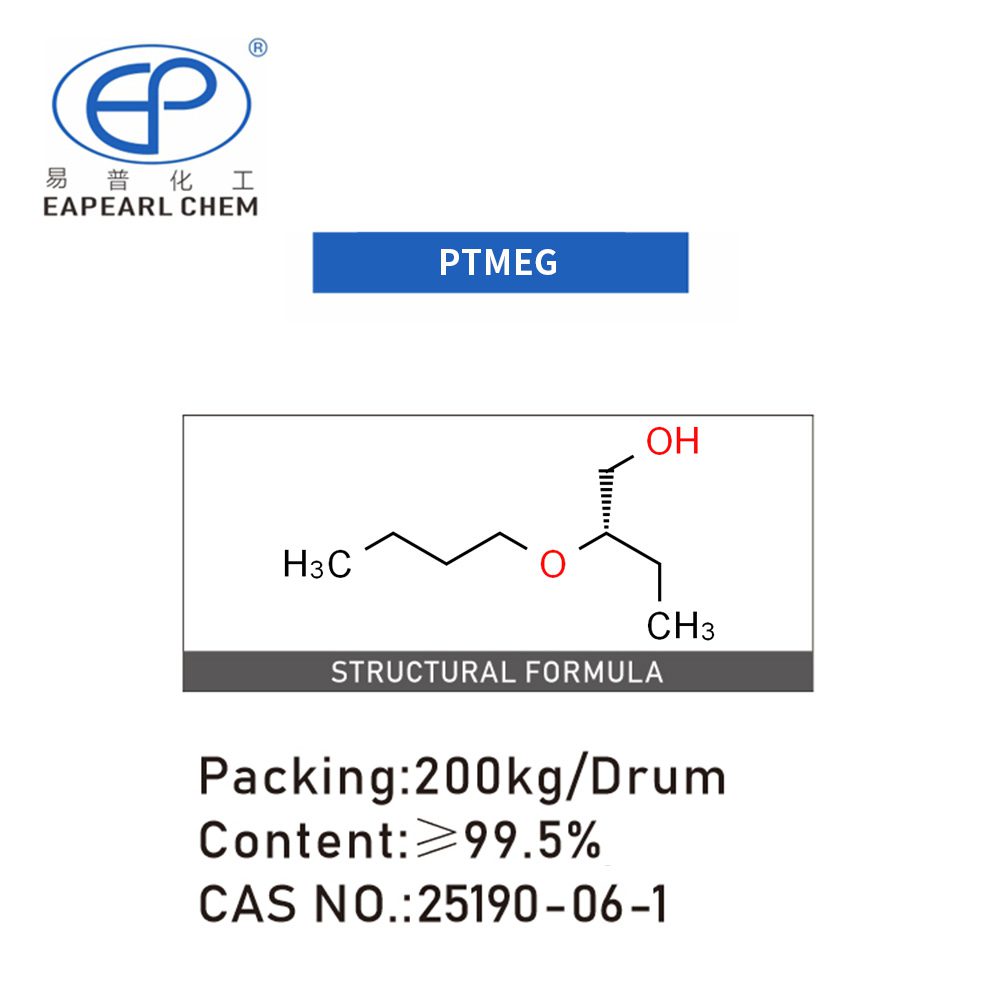

PTMEG

PTMEG, or polytetramethylene ether glycol, is a fascinating substance with unique properties. PTMEG appears as a white waxy material in its solid form, but as soon as the temperature surpasses room temperature, it transforms into a clear and fluid liquid. It exhibits intriguing solubility characteristics, dissolving readily in alcohols, esters, ketones, aromatics, and chlorinated hydrocarbons. However, it remains insoluble in esters and water. Interestingly, the solubility of PTMEG diminishes as its molecular weight increases.

One noteworthy attribute of PTMEG is its affinity for water absorption when exposed to room temperature. The extent of water absorption relies on the molecular weight, with the highest grade capable of absorbing up to 2% of its weight in water. This exceptional property adds to the versatility and potential applications of PTMEG in various fields.

| Product Name: | PTMEG |

|---|---|

| CAS No.: | 25190-06-1 |

| Purity | ≥99.5% |

| Packing: | 1ton/drum, 200kg/drum |

| HScode: | 39072020 |

We use the latest network security technology to protect your personal information from leakage, and to ensure that you can shop safely and securely.

Share

Description:

Preparation method:

Tetrahydrofuran (THF) is typically synthesized in the industry using different initiators such as acetic hydride-perchloric acid, chlorosulfonic acid, or sulfuric acid. These initiators facilitate the reaction to produce THF with a molecular weight ranging from 600 to 3000 and containing hydroxyl groups.

The synthesis process involves the following steps:

1. Acetic hydride-perchloric acid method:

- Acetic hydride (also known as acetic anhydride) and perchloric acid are combined in the presence of a catalyst.

- The reaction mixture is heated to a specific temperature, typically under reflux conditions.

- The acetic hydride-perchloric acid combination acts as an initiator, initiating the polymerization of the starting materials.

- The resulting reaction mixture undergoes further processing to purify and isolate the desired Tetrahydrofuran product.

2. Fluorosulfonic acid method:

- Fluorosulfonic acid, a strong acid, is an initiator in this method.

- The reaction is typically carried out by adding chlorosulfonic acid to a suitable solvent, which may also act as a reactant.

- The mixture is then heated to a specific temperature, allowing the chlorosulfonic acid to initiate polymerization.

- Post-reaction steps are performed to purify and recover Tetrahydrofuran with the desired molecular weight and hydroxyl group content.

3.Sulfuric acid method:

- Sulfuric acid is employed as the initiator in this method.

- Like the chlorosulfonic acid method, the sulfuric acid is added to a suitable solvent or reactant.

- The mixture is heated, and the sulfuric acid initiates the polymerization reaction to form Tetrahydrofuran.

- Further purification and isolation steps are carried out to obtain Tetrahydrofuran with the desired properties.

It’s important to note that the exact reaction conditions, catalysts, and purification methods can vary depending on the specific industrial process and requirements. These methods are intended to provide a general understanding of how Tetrahydrofuran can be synthesized using acetic hydride-perchloric acid, chlorosulfonic acid, or sulfuric acid as initiators.

Synonyms:

Characteristics:

| Molecular Formula | C16H33O5X2 |

| Molar Mass | 305.43 |

| Density | 1g/mLat 25°C |

| Melting Point | 33-36°C |

| Boling Point | 195.7°C at 760 mmHg |

| Flash Point | >230°F |

| Vapor Presure | <0.01 mm Hg ( 25 °C) |

| Specific Gravity | 1 |

| PH | 7 (H2O, 20℃)Aqueous solution |

| Storage Condition | Store below +30°C. |

| Refractive Index | n20/D 1.465 |

| Physical and Chemical Properties | Polytetrahydrofuran is a white waxy solid that dissolves readily in alcohols, esters, ketones, aromatic hydrocarbons, and chlorinated hydrocarbons, and is insoluble in ester hydrocarbons and water, and becomes a transparent liquid when the temperature exceeds room temperature. |

Use

FAQ:

Q1. What is PTMEG?

A1. PTMEG, known as polytetramethylene ether glycol, is an exceptional polymeric polyol utilized as a raw material in manufacturing diverse products. These products include polyurethane elastomers, coatings, adhesives, and synthetic fibers. PTMEG imparts exceptional flexibility, durability, and resilience to the final products.

Q2. What are the benefits of using PTMEG?

A2. PTMEG offers numerous key advantages, including:

- Superior hydrolytic stability and resistance to harsh environmental conditions.

- Excellent mechanical properties include high elasticity, low-temperature flexibility, and tear resistance.

- Enhanced resistance to abrasion, chemicals, and oils.

- Compatibility with other materials, making it suitable for various applications.

- Customizable molecular weight options to meet specific requirements.

Q3. In what applications can PTMEG be utilized?

A3. PTMEG finds a wide range of applications across diverse industries, such as:

- Manufacturing spandex fibers and elastic textiles.

- Producing high-performance polyurethane (PU) elastomers and thermoplastic polyurethanes (TPU).

- Formulating coatings, adhesives, and sealants with improved flexibility and durability.

- Usage in the production of synthetic leather, films, and medical products.

- Incorporation into urethane casting resins, elastomers, and foams.

Q4. How is PTMEG manufactured?

A4. PTMEG is produced by polymerizing tetrahydrofuran (THF) using a catalyst. The process involves the reaction of THF with an initiator, forming a linear polymer chain. This chain is then terminated with a hydroxyl (-OH) group, making it suitable for further reactions in polyurethane and other applications.

Q5. What are the available molecular weight options for PTMEG?

A5. PTMEG is available in a range of molecular weights, typically expressed as a numerical value followed by “g/mol.” The molecular weight determines the physical properties of the final product. Common molecular weight options include PTMEG-650, PTMEG-1000, PTMEG-2000, PTMEG-3000, and PTMEG-4000.

Q6. What are the storage and handling requirements for PTMEG?

A6. To ensure the integrity of PTMEG, it should be stored in a cool, dry, and well-ventilated area, away from direct sunlight, heat, and ignition sources. It is important to prevent moisture ingress, as it can degrade the product. During handling, it is advisable to use appropriate personal protective equipment (PPE), such as gloves and safety goggles, to ensure safe handling and minimize the risk of skin or eye contact.

Q7. How is PTMEG packaged and delivered?

A7. PTMEG is typically packaged in high-quality, sealed containers to preserve its purity and quality. The containers’ size may vary depending on the quantity ordered. We work closely with our customers and distributors to ensure safe and efficient delivery methods. These methods may include drums, totes, or bulk shipments, tailored to individual requirements.

Q8. Can PTMEG be customized for specific applications?

A8. Absolutely! PTMEG can be customized to meet specific application requirements. Our experienced team is dedicated to working with you, understanding your needs, and developing tailored solutions. We offer options such as molecular weight adjustments, special packaging, or other modifications to ensure optimal performance in your desired application.

Q9. Are there any safety precautions to consider when using PTMEG?

A9. When handling PTMEG, it is essential to adhere to standard safety procedures. Avoid prolonged or repeated contact with the skin or eyes, and ensure good ventilation in the working area to prevent inhalation of vapors. In case of contact, promptly rinse affected areas with plenty of water and seek medical attention if necessary. For detailed safety information, please refer to the material safety data sheet (MSDS) or contact our team for assistance.

Q10. How can I place an order or request additional information about PTMEG?

A10. To place an order or obtain further information about PTMEG, please get in touch with our sales team via phone, email, or our online inquiry form. Our knowledgeable representatives are eager to assist you with any questions, provide technical support, and guide you through ordering.

相关产品

Loading Video or Picture: