Triethylene Glycol (TEG)

Your Trusted Source for High-Quality Triethylene Glycol

Discover the key to efficient moisture control and superior product quality

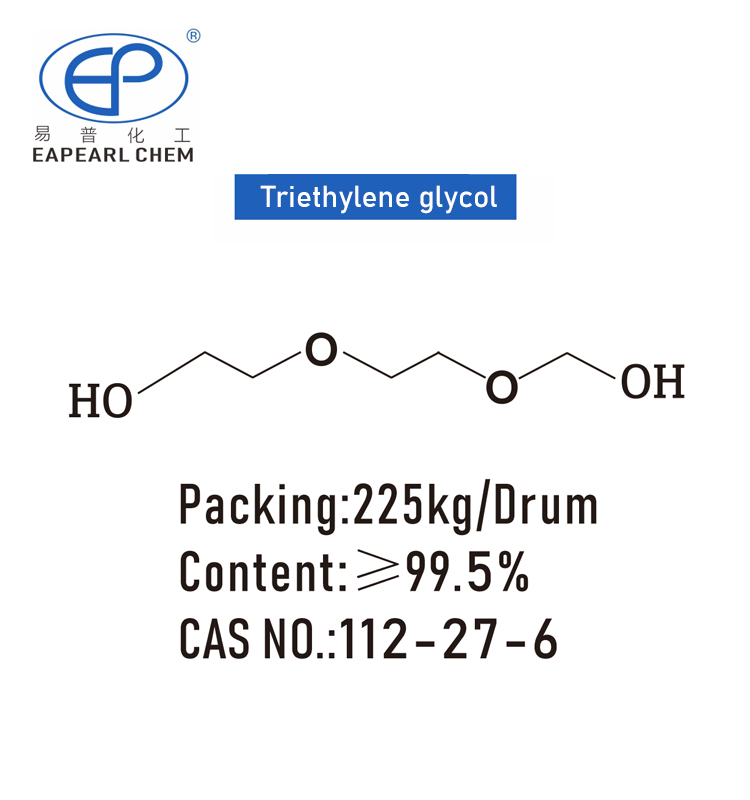

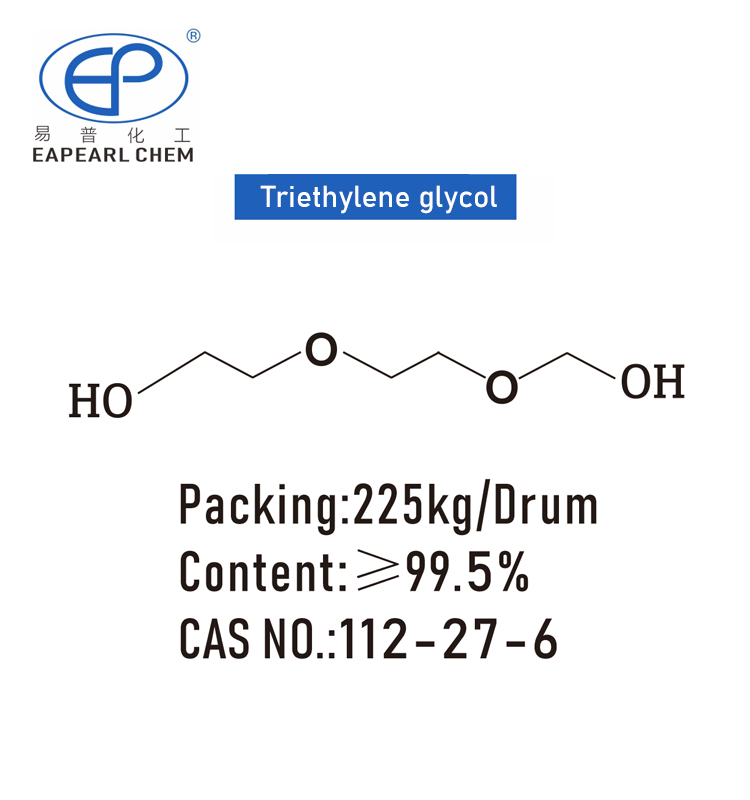

| CAS | 112-27-6 |

| chemical formula | C6H14O4 |

| molecular weight | 150.17 |

| purity | ≥99.5% |

| packing | 225kg/drum |

Are you in search of a versatile solution for moisture management in modern industrial applications? Look no further than Triethylene Glycol(also known as TEG, TGME, Trigol, Triglycol, Triethylenglycol, TRIETHYLENE GYCOL, 2,2-(ethylenedioxy)diethanol, triethylene glycol anhydrous, 2,2′-(1,2-ethanediylbis(oxy))bisethanol). This colorless, odorless, and stable liquid is a game-changer with its high viscosity and high boiling point. What sets TEG apart is its exceptional water absorption capability and low volatility, making it the ultimate choice for tackling moisture-related challenges.

Eapearl’s triethylene glycol (TEG) guarantees a consistently high quality raw material, which is essential for the production of vinyl polymers. What’s even more impressive? Eapearl can be shipped within seven days eliminating any concerns about inventory issues disrupting production cycles.

Eapearl offers more than just chemicals, it provides a versatile solution for improving operational efficiency. Backed by advanced technology and strict quality control, we promise to optimize your industrial processes, improve your operational efficiency and ensure the quality of your products.

With Eapearl’s 15 years of expertise, commitment to quality and efficient delivery, partnering with Eapearl is not just a product purchase, but an investment in a solution that will improve our margins and contribute to our long-term success.

Triethylene Glycol (TEG) Information

| TEG packaging | capacity | 20GP | 40GP |

| drum | 225 kg /drum | total 80 drums, Net 18 ton | total 108 drums, Net 24.3 ton |

| IBC drum 1 | 1 ton /IBC | total 20 IBC drums, Net 20 ton | total 26 IBC drums, Net 26 ton |

| IBC drum 2 | 1.12 ton /IBC | total 18 IBC drums, Net 20.16 ton | total 23 IBC drums, Net 25.76 ton |

| flexibag | 25 ton /flexibag | 1 flexibag, Net 25 ton | N/A |

| ISO Tank | 25 ton /ISO Tank | 1 ISO Tank, Net 25 ton | N/A |

For triethylene glycol, we welcome you to test and check the quality, if you need a sample please contact our sales team to discuss your sample requirements, we believe that our product quality is suitable for the specific application, we provide samples free of charge but the shipping cost will be borne by you.

Preparation of Triethylene Glycol (TEG)

Triethylene glycol is prepared commercially as a co-product of the oxidation of ethylene at high temperature, in the presence of a silver oxide catalyst. The ethylene oxide is then hydrated to yield mono, di, tri, and tetra ethylene glycols. Here’s a more detailed explanation of the process:

Oxidation of Ethylene: The commercial production of TEG often starts with the oxidation of ethylene (C2H4) at high temperatures in the presence of a silver oxide (Ag2O) catalyst. This process leads to the formation of several products, including ethylene oxide (EO) and other oxygenated compounds.

Collection of Ethylene Oxide: Ethylene oxide (EO) is a key intermediate product in this process and is collected for further use in the production of glycols.

Hydration of Ethylene Oxide: The collected ethylene oxide is then subjected to hydration, which is the addition of water (H2O) to ethylene oxide. This hydration process leads to the formation of various glycols, including monoethylene glycol (MEG), diethylene glycol (DEG), triethylene glycol (TEG), and sometimes even tetraethylene glycol (TTEG).

Fractionation and Separation: After the hydration step, the mixture contains a combination of these glycols along with unreacted ethylene oxide and other by-products. Fractionation and separation techniques are used to separate and isolate the individual glycols based on their different boiling points. This step allows for the purification and collection of TEG.

Purification and Packaging: The separated TEG is then further purified to remove any remaining impurities. Once the desired level of purity is achieved, the TEG product is packaged and prepared for distribution and use in various industrial applications.

How can we handle your order?

step 1

We will communicate with you within 24 hours after you send an enquiry.

step 2

If you need sample testing, we will send samples within 5 days,≤50kg, Express delivery recommended, usually called as DDU service; delivery time 5-7 days. Door to door service.

step 3

If you need bulk goods after the sample test is qualified, we will ship the goods to the port and keep the samples within 6 days after the order is confirmed. Sea shipping recommended, usually called as FOB, CFR, or CIF service.delivery time 10-45 days. Port to port service.

step 4

After waiting for you to receive the goods, we will arrange professional staff to pay a return visit within 7 days.

Technical of Triethylene Glycol (TEG)

| Molecular Formula | C6H14O4 |

| Molar Mass | 150.17 |

| Density | 1.124g/mLat 20°C(lit.) |

| Melting Point | −7°C(lit.) |

| Boling Point | 125-127°C0.1mm Hg(lit.) |

| Flash Point | 165 °C |

| Water Solubility | SOLUBLE |

| Solubility | It is miscible in alcohol and benzene, miscible with water, slightly soluble in ether, insoluble in petroleum ether. |

| Vapor Presure | <0.01 mm Hg ( 20 °C) |

| Vapor Density | 5.2 (vs air) |

| Appearance | viscous liquid |

| Color | Clear very slightly yellow |

| Odor | Very mild, sweet. |

| Maximum wavelength(λmax) | [‘λ: 260 nm Amax: 0.06’, ‘λ: 280 nm Amax: 0.03’] |

| Merck | 149,670 |

| BRN | 969357 |

| pKa | 14.06±0.10(Predicted) |

| PH | 5.5-7.0 (25℃, 50mg/mL in H2O) |

| Storage Condition | Store below +30°C. |

| Stability | Stable. Combustible. Incompatible with strong oxidizing agents. |

| Sensitive | Hygroscopic |

| Explosive Limit | 0.9-9.2%(V) |

| Refractive Index | n20/D 1.455(lit.) |

| MDL | MFCD00002880 |

| Physical and Chemical Properties | Colorless, odorless and hygroscopic viscous liquid. melting point -4.3 ℃ boiling point 288 ℃ relative density 1.1254 refractive index 1.4561 flash point 165.85 ℃ solubility miscible with water and ethanol, slightly soluble in ether, almost insoluble in petroleum ether. |

| LogP | -1.75 at 25℃ |

| Toxicity | LD50 in mice, rats (g/kg): 21, 15-22 orally; 7.3-9.5, 11.7 i.v. (Stenger) |

| HS Code | 29094919 |

| Specific Gravity | 1.122~1.125 |

| EINECS | 203-953-2 |

| explosive limit | n20/D 1.455(lit.) |

Downloadable Documents of Triethylene Glycol (TEG)

COA of TEG

TDS of TEG

MSDS of TEG

REQUEST A QUOTE FOR MORE DETAILS

Triethylene Glycol (TEG) Application

Oil & Gas Industry

Triethylene Glycol (TEG) plays a crucial role in the Oil & Gas industry, primarily leveraging its hygroscopic properties. The main applications in this sector include:

Dehydrating Agent for Natural Gas Pipelines: TEG serves as a highly effective dehydrating agent in natural gas pipelines. It absorbs moisture from the air, removing water from the gas before condensation. This process prevents the gas from freezing, ensuring easier transportation and management for end consumers.

Continuous Reuse: TEG’s ability to absorb and remove moisture allows for its continuous reuse in the dehydrating process. However, it’s important to note that the by-product of benzene generated in this process requires careful disposal.

Mild Disinfectant

Triethylene Glycol (TEG) serves as a versatile mild disinfectant, finding application in various settings. Here’s how TEG is utilized:

Air Disinfection: TEG is commonly employed as a mild disinfectant for air in occupied areas. Its low toxicity, antimicrobial properties, and subtle odor make it suitable for use in environments where more aggressive disinfectants may not be feasible.

Dehumidifying Agent in Air-Conditioning Units: TEG’s disinfectant properties, combined with its dehydrating characteristics, make it an ideal choice as a dehumidifying agent in air-conditioning units. It helps maintain a comfortable and sanitized indoor environment.

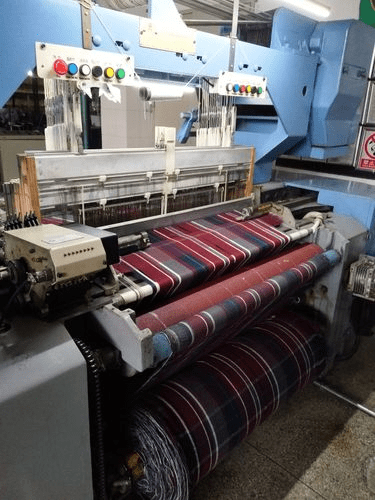

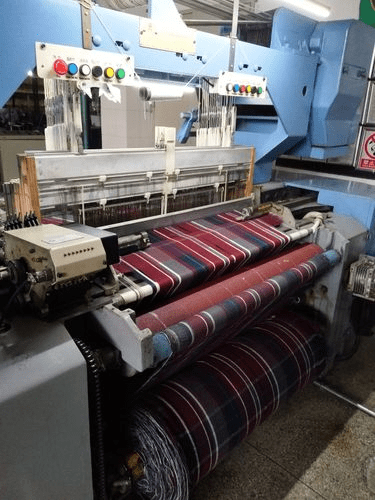

Textile Industry

Triethylene glycol (TEG) plays a significant role in the textile industry, primarily due to its hygroscopic and solvent properties. Here are some ways TEG is utilized in this sector:

Moisture Control: TEG’s ability to absorb moisture from the air is beneficial in maintaining optimal humidity levels during textile processing, which can be crucial for certain fabrics.

Fabric Conditioning: It is used in fabric conditioning treatments to help maintain the softness and manageability of textiles.

Dye Solvent: As a solvent, TEG can help dissolve dyes and other treatment chemicals, ensuring even application and penetration in the textile fibers.

Fiber Lubrication: TEG can act as a lubricant in the spinning of fibers, aiding in the production of smoother, less tangled yarns.

Printing Processes: In textile printing, TEG can be used as a solvent to create inks and dyes that have the desired consistency and application properties.

Resins

Triethylene Glycol (TEG) is commonly used in the production of resins, particularly in the following applications:

Polyester Resin Production: TEG is a key component in the manufacturing of polyester resins. These resins play a crucial role in producing a variety of products, including fiberglass reinforced plastics, laminates, and other composite materials.

Alkyd Resin Manufacturing: TEG is used in the production of alkyd resins, which are widely employed in the formulation of paints, coatings, and varnishes. Alkyd resins provide durable and glossy finishes in various applications.

Polyurethane Resins: TEG is sometimes incorporated into the formulation of polyurethane resins. These resins find applications in coatings, adhesives, sealants, and elastomers, contributing to their flexibility and durability.

Epoxy Resin Processing: TEG may be utilized in certain formulations of epoxy resins. Epoxy resins are known for their strong adhesive properties and are used in a range of applications, including construction, electronics, and coatings.

Other Industries

Certainly! Triethylene Glycol (TEG) exhibits remarkable properties, making it versatile across various industries. Here are some key applications:

High-Temperature Heat Transfer: TEG’s superior thermal stability, up to 204 °C (400 °F), makes it a preferred choice for high-temperature heat transfer applications.

Corrosion Protection: TEG is utilized to protect systems from corrosion, ensuring the longevity and reliability of equipment.

Solvent for Chemical Adhesives and Fillers: TEG serves as a soluble solvent in the formulation of chemical adhesives and fillers.

Absorbers: TEG is employed as an absorber in various processes, contributing to its effectiveness in specific industrial applications.

Fuels and Fuel Additives: TEG finds use in the formulation of fuels and fuel additives, contributing to their properties and performance.

Dry Cleaning: TEG is utilized in the dry cleaning industry for its solvent properties.

Electronics and Electrical Materials: TEG is employed in the production of materials for electronics and electrical applications.

UV-Curable Resins: TEG plays a role in the formulation of UV-curable resins, which find applications in coatings and adhesives.

Lubricant: TEG is used as a component in lubricants, contributing to their performance in various applications.

The diverse range of applications showcases TEG’s adaptability and reliability across different industries. If you have specific questions or need more detailed information about any of these applications, feel free to ask. I’m here to provide the insights you need for your business considerations.

REQUEST A QUOTE FOR MORE DETAILS

Knowledge Base of Triethylene Glycol (TEG)

Feedback of Triethylene Glycol (TEG)

Tomas Garcia, Mexico

We have been using Ttriethylene Glycol from you for a while now, and we are very impressed with the quality of the product. It is reliable and consistent, and it has helped us to streamline our production process. We have been so pleased with the product that we have chosen to make your company our regular supplier.

Jasmine Lee, Singapore

We had previously purchased Triethylene Glycol from another supplier, but the quality needed improving, and we lost a long-term customer. After seeing your information, we decided to try your product and purchase it for our customers. We have been delighted with the results, and our customers have given us positive feedback. We highly recommend your product to anyone looking for a reliable, cost-effective solution.

FAQs of Triethylene Glycol (TEG)

What is triethylene glycol used for?

Triethylene glycol (TEG) shares similarities with diethylene glycol (DEG) but has a higher boiling point, viscosity, and specific gravity. It’s chosen for applications requiring a high boiling point and low volatility. The primary use of TEG is in drying natural gas, thanks to its strong hygroscopic properties. Additionally, TEG serves as a chemical intermediate in producing vinyl plasticizers, polyester resins, adhesives, and various solvents and cleaners.

How is the quality?

The purity of the triethylene glycol products exported by our company has reached more than 99.5%, and the quality is excellent with competitive pricing.

What are the payment options?

You can use Western Union, which has a lower fee, or PayPal if you can accept a slightly higher fee, but please note that for new customers, we only accept the 30% T/T of the payment, or if you have been with us for years and run into cash flow pressure, we do offer OA credit.

How long does it usually take for me to receive the goods?

Depending on the speed of customs clearance and logistics, we can guarantee that the product will be shipped to the port within 5 working days of the order being confirmed, and we have customers in Singapore who receive the goods within 3 weeks.

What is your minimum order quantity for triethylene glycol?

For triethylene glycol, our minimum order quantity is 1 ton. Of course, if you order a large quantity, we can give you a discount on the price.

What information should I let you know if I want to get a quote?

As a supplier, in order to provide you with an accurate quote for your product, please inform us of the quantity you require, the required purity specifications, any specific packaging needs, your shipping location, and whether your application requires any customization requirements or certifications.