Tetraethylene Glycol

Leading the Market with Eapearl's Tetraethylene Glycol - The Pinnacle of Purity and Efficiency.

Step into the Future of Industrial Excellence with Eapearl – Where Quality is Never Compromised.

Tetraethylene Glycol (TTEG) Purity and Information

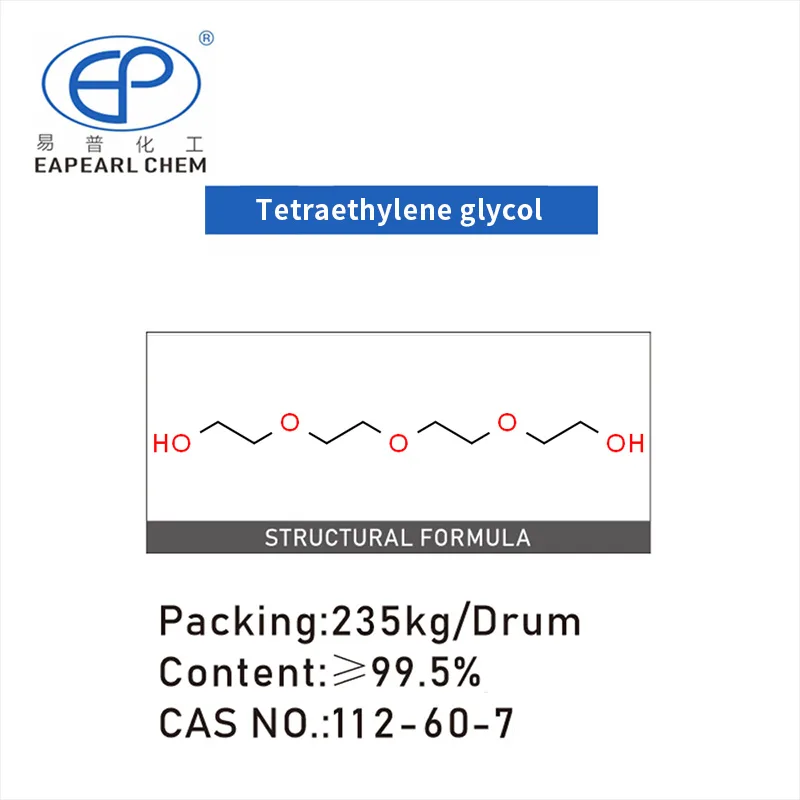

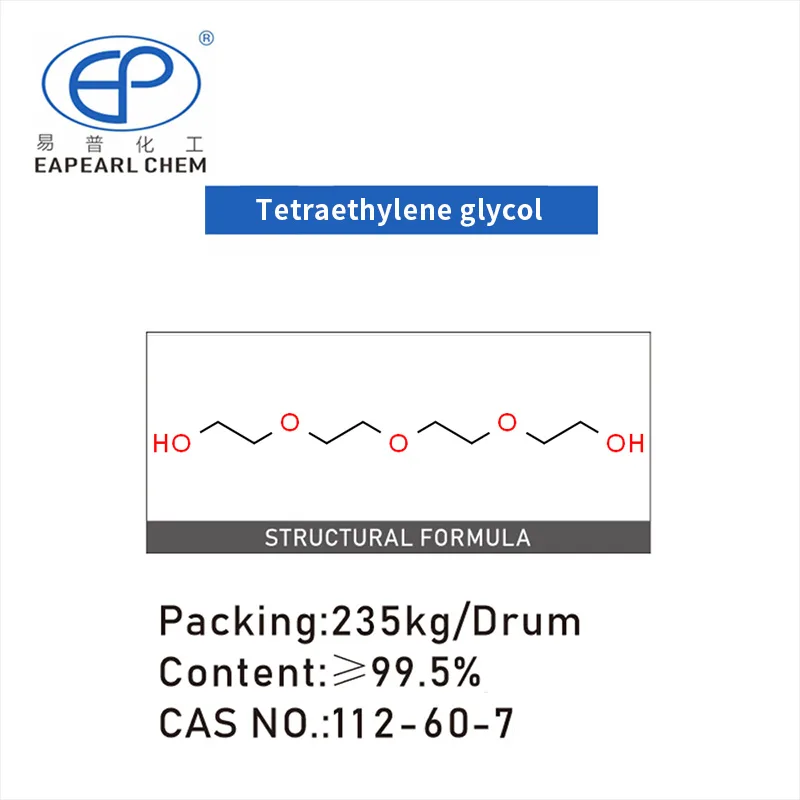

| Product Name: | Tetraethylene glycol,TTEG,tetraglycol |

| Synonyms: | tetragol GLYCOFUROL Tetraethyleneglycol Tetraethylene glycol Tetra Ethylene Glycol (TTEG) 3,6,9-trioxaundecane-1,11-diol |

| CAS No.: | 112-60-7 |

| EINECS.: | 203-989-9 |

| chemical formula: | C8H18O5 |

| molecular weight: | 194.225 |

| Purity | 99.5% |

| Packing: | 235kgs/drum |

Tetraethylene Glycol (TTEG) Packing Instruction

| TTEG Packaging | Capacity | 20GP | 40GP |

| Drum | 235kgs/drum | total 80 drums, Net 18.8 Tons | total 120 drums, Net28.2 Tons |

| IBC Drum | 1 tons/IBC drum | total 20 IBCdrums, Net 20 Tons | total 23-26 IBCdrums, Net 23-26 Tons |

| Flexibag | 25 Tons | 1Flexibag, Net 25 Tons | N/A |

| ISOTank | 25 Tons | 1ISO Tank, Net 25 Tons | N/A |

Production Technology of Tetraethylene Glycol (TTEG)

| Aspect | Ethylene Oxide Polymerization | Oxidative Coupling of Ethylene | Hydrolysis of Ethylene Glycol Ethers |

|---|---|---|---|

| Process Overview | Reacting ethylene oxide with water. | Oxidative coupling of ethylene. | Hydrolyzing ethylene glycol ethers. |

| Catalytic Process | Acidic or basic catalysts. | Silver-based catalyst. | Acidic conditions. |

| Reaction Mechanism | Polymerization of EO with water. | Oxidative coupling of ethylene molecules. | Reaction of the ether with water. |

| Product Distribution | Mixture of ethylene glycols (MEG, DEG, TEG, TTEG). | Less selective; potential for higher glycols. | Direct route to TEG. |

| Yield and Purity | High yield; varying purity. | Lower yield; varying selectivity and purity. | High purity; lower yield. |

| Quality Control | Regular monitoring of conditions and composition. | Monitoring reaction conditions and catalyst. | Emphasis on reactant and product purity. |

| Safety Measures | High due to reactive materials and conditions. | High, especially with oxygen and intermediates. | Moderate; handling of acidic conditions. |

| Advantages | High efficiency, scalability. | Selective production potential. | High purity product. |

| Disadvantages | Stringent reaction control, high energy consumption. | Less selective, higher catalyst cost. | Lower yield, specific raw material needs. |

| Cost Implications | Cost-effective, high operational costs. | Higher per-unit cost. | Higher raw material cost, offset by purity. |

The Application of Tetraethylene Glycol (TTEG)

| Industry/Application | Use of Tetraethylene Glycol (TEG) | Benefits |

|---|---|---|

| Solvent Production | Used as a solvent in paints, inks, and varnishes. | Enhances solubility and improves the consistency of the final product. |

| Plastics Industry | Utilized in the production of plasticizers. | Contributes to the flexibility and durability of plastics. |

| Textile Industry | Employed in the manufacturing of textile fibers. | Aids in improving fiber quality and texture. |

| Polyurethane Production | Used in the formulation of polyurethanes. | Enhances the properties of polyurethanes, such as flexibility and resistance. |

| Adhesives Manufacturing | Applied in adhesive formulations. | Improves adhesive qualities like tackiness and drying time. |

| Lubricant Industry | Acts as a lubricant in various mechanical and industrial processes. | Reduces friction and wear, enhancing equipment lifespan. |

| Hydraulic and Brake Fluids | Component in the formulation of hydraulic and brake fluids. | Improves fluid performance under extreme temperatures. |

| Cosmetic and Personal Care Products | Used in cosmetic formulations. | Enhances texture and stability of products like lotions and creams. |

| Pharmaceutical Industry | Employed in drug formulations and medical supplies. | Serves as a solvent or carrier for active pharmaceutical ingredients. |

| Coolant Systems | Utilized in coolant systems due to its thermal properties. | Efficient in heat transfer and temperature regulation. |

How can we handle your order?

step 1

We will communicate with you within 24 hours after you send an enquiry.

step 2

If you need sample testing, we will send samples within 5 days,≤50kg, Express delivery recommended, usually called as DDU service; delivery time 5-7 days. Door to door service.

step 3

If you need bulk goods after the sample test is qualified, we will ship the goods to the port and keep the samples within 6 days after the order is confirmed. Sea shipping recommended, usually called as FOB, CFR, or CIF service.delivery time 10-45 days. Port to port service.

step 4

After waiting for you to receive the goods, we will arrange professional staff to pay a return visit within 7 days.

REQUEST A QUOTE FOR MORE DETAILS

Technical of Tetraethylene Glycol (TTEG)

| Name | Tetraethylene glycol,TTEG,Tetragol |

| Molecular Formula | C8H18O5 |

| Molar Mass | 194.225 |

| Density | 1.111g/cm3 |

| Melting Point | -4.1℃ |

| Boling Point | 328°C at 760 mmHg |

| Flash Point | 176.7°C |

| Water Solubility | soluble |

| Vapor Presure | 1.47E-05mmHg at 25°C |

| Vapor Density | 6.7 (vs air) |

| Appearance | Clear slightly yellow liquid |

| pKa | 14.06±0.10(Predicted) |

| PH | 8.5-9.0 (500g/l, H2O, 20℃) |

| Storage Condition | Store below +30°C. |

| Stability | Stable. Incompatible with strong oxidizing agents, strong bases. |

| Refractive Index | 1.455 |

| Physical and Chemical Properties | 9004-76-6 |

Qualifications and Documents of TTEG

Market Analysis About Tetraethylene Glycol (TTEG)

Here’s a tabular representation of some of the most advantageous countries for TTEG production, highlighting key factors that contribute to their advantageous position:

| Country | Advantages |

| United States | – Robust Petrochemical Industry: Extensive ethylene production. – Advanced Technology: Leading-edge manufacturing technologies. – Market Access: Large domestic market and global trade connections. – Regulatory Framework: Strong intellectual property laws and business-friendly policies. |

| China | – Large Scale Production: Massive industrial capacity for large volume production. – Cost-Effectiveness: Competitive labor and production costs. – Strategic Location: Access to Asian markets and global export routes. – Government Support: Policies favoring industrial growth and export-oriented manufacturing. |

| Saudi Arabia | – Raw Material Abundance: Access to crude oil and natural gas, key feedstocks for ethylene. – Government Incentives: Substantial investment in petrochemical sector. – Export-Oriented Production: Geographical advantage for global shipping. – Growing Domestic Market: Increasing demand within the Middle East. |

| Germany | – Technological Leadership: Innovation in chemical processing technologies. – Quality Standards: High-quality production standards. – Skilled Workforce: Highly trained and specialized labor force. – Market Integration: Strong presence in the European Union market. |

Why the Chinese Market Stands Out for Tetraethylene Glycol (TTEG) Production

The Chinese market stands out in the production of Tetraethylene Glycol (TTEG) for several key reasons, making it a focal point in the global chemical industry:

1. Massive Industrial Capacity

- China has one of the world’s largest and most diverse industrial bases. This vast capacity allows for significant production of TTEG, meeting both domestic and international demands.

2. Cost-Effective Manufacturing

- Labor Costs: Lower labor costs in China compared to many Western countries contribute to more affordable production expenses.

- Supply Chain Efficiency: China’s well-established supply chains for raw materials and intermediates reduce production costs and time.

- Government Incentives: Government policies and subsidies often favor the chemical industry, leading to more favorable production conditions.

3. Advanced Technological Infrastructure

- Continuous investment in technology and infrastructure in the chemical sector leads to modernized and efficient production facilities.

- Chinese manufacturers often adopt the latest technologies to enhance production efficiency and quality.

4. Strategic Export Capabilities

- China’s strategic geographical location facilitates easy access to key export markets in Southeast Asia, South Asia, and beyond.

- Robust export infrastructure, including major ports and logistic networks, supports large-scale exports of chemical products.

5. Growing Domestic Market

- China’s expanding economy and industrial sector create a substantial domestic demand for TTEG, which in turn drives production and innovation in the sector.

6. Global Integration

- Participation in global trade organizations and bilateral trade agreements enhances China’s ability to trade efficiently with many countries.

FAQs of Tetraethylene Glycol (TTEG)

About Purchasing Requirements

A1: The minimum order quantity for TTEG varies based on product grade and availability. Please contact our sales team for specific details.

A2: Orders can be placed through our online platform, via email, or by contacting our sales representatives directly.

About Product Quality and Specifications

A3: Our TTEG typically has high purity levels, suitable for various industrial applications. Exact specifications can be provided upon request.

A4: Yes, our TTEG is produced in compliance with international standards and comes with all necessary certifications, including ISO and REACH.

Regarding Cost and Pricing

A5: Pricing is based on market conditions, order volume, and specific product specifications. We offer competitive pricing and can provide a quote upon request.

A6: Yes, we offer volume discounts for large-scale orders. Please contact our sales team for more information.

Concerning Supply Chain and Delivery

A7: Lead times vary depending on order size and destination. We strive to expedite orders while ensuring product quality.

A8: We have robust supply chain management practices, including strategic stockpiling and diversified sourcing, to ensure continuous supply.

Add Your Heading Text Here

A9: TTEG is used in various industries, including as a solvent in paints, in the production of plasticizers, and in textile manufacturing.

A10: Yes, we offer comprehensive technical support, including product selection advice and application guidance.

On Sustainability and Corporate Responsibility

A11: We are committed to sustainable production practices, including energy-efficient processes and waste reduction initiatives.

A12: Our approach to corporate social responsibility includes ethical business practices, community engagement, and a commitment to environmental stewardship.