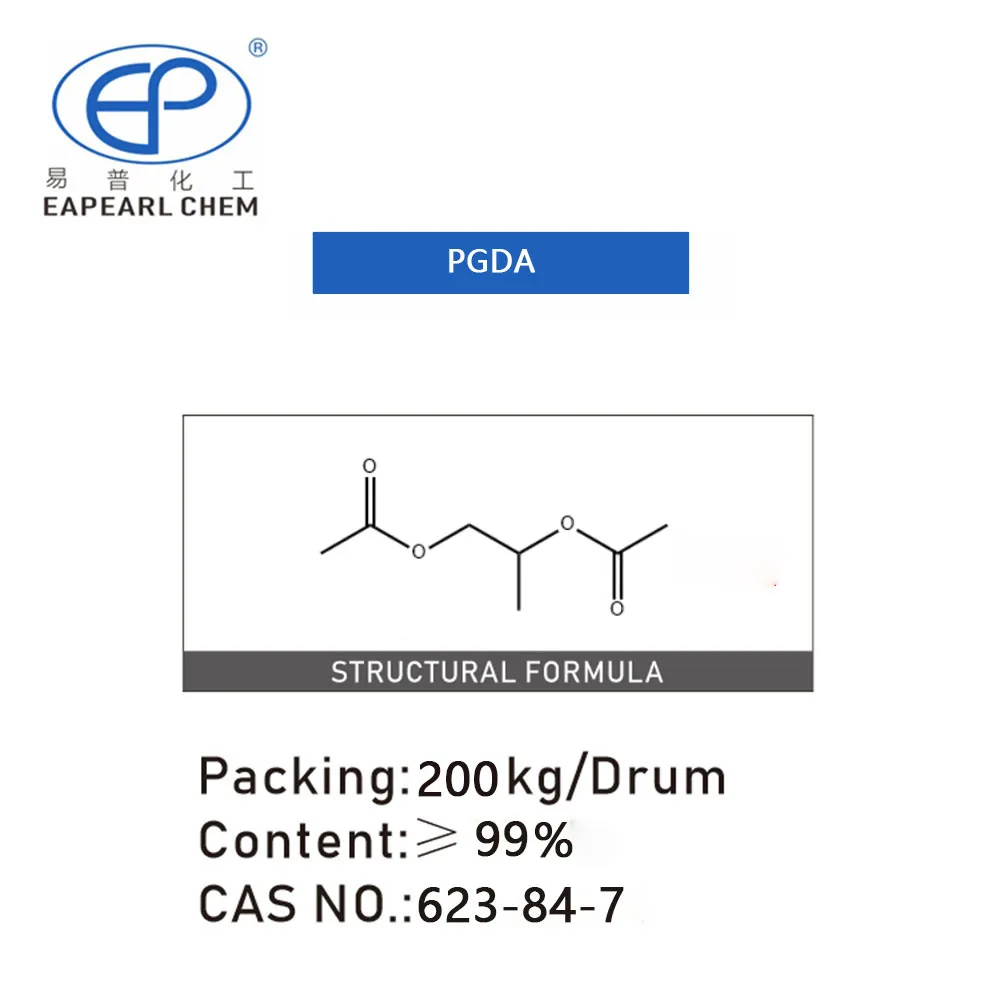

1,2-Propylene Diacetate(PGDA)

| Product Name | 1,2-Propylene diacetate |

| CAS | 623-84-7 |

| EINECS | 210-817-6 |

| Chemical Formula | C7H12O4 |

| Molecular Weight | 160.17 |

| Purity | ≥99% |

| Grade | industrial grade |

This diacetate ester, also known as 1,2-propanediol diacetate, propylene diacetate, propylene glycol diacetate, methylethylene diacetate, propane-1,2-diyl diacetate, short for PGDA, presents as a colorless to almost colorless liquid, very mild fruity acetic aroma.

PGDA is a functional environmentally friendly solvent with the general chemical properties of esters. Easy to dissolve in alcohol, ether and other organic solvents, with excellent leveling, low odor, safety and non-toxic, strong solubility, good bubble inhibition, strong dispersion of pigments. It has the advantages of anti-floating color, anti-white paint film, anti-heat rash, etc. It is an efficient, environmentally friendly and functional organic solvent.

Eapearl stands out for our high-quality PGDA and unwavering commitment to excellence. We guarantee consistently superior raw materials, ensuring efficient delivery within seven days. Our solutions, backed by advanced technology and stringent quality control, are designed to optimize industrial processes and improve product quality. With 15 years of expertise, we prioritize efficient collaboration, aiming to enhance our partners’ bottom line and ensure their long-term success. Our dedication to quality, efficiency, and customer satisfaction positions us as a reliable and valuable partner in the industry.

PGDA Packaging Information

| DPMA packaging | capacity | 20GP | 40GP |

| drum | 200 kg /drum | total 80 drums, Net 16 ton | total 128 drums, Net 25.6 ton |

| IBC | 1 ton /IBC | total 20 IBC, Net 20 ton | total 26 IBC, Net 26 ton |

| flexibag | 24 ton /flexibag | 1 flexibag, Net 24 ton | N/A |

| ISO Tank | 24 ton /ISO Tank | 1 ISO Tank, Net 24 ton | N/A |

For PGDA, we welcome you to test and check the quality, if you need a sample please contact our sales team to discuss your sample requirements, we believe that our product quality is suitable for the specific application. We provide samples free of charge but the shipping cost will be borne by you.

Preparation Method of PGDA

The preparation of 1,2-Propyleneglycol diacetate (PGDA) typically involves an esterification process, where propylene glycol reacts with acetic acid. Here is a general outline of the method used for preparing PGDA:

Mixing: Propylene glycol and acetic acid are mixed in the reactor in a specific molar ratio, typically with an excess of acetic acid to drive the reaction towards ester formation.

Catalyst Addition: The catalyst such as sulfuric acid, p-toluenesulfonic acid, or an acidic ion exchange resin is introduced to the mixture to facilitate the esterification.

Heating and Reaction: The mixture is heated to a suitable temperature (usually around 120-150°C) to initiate and sustain the reaction. The propylene glycol reacts with acetic acid, forming PGDA and water as a by-product.

Monitoring: The reaction progress is typically monitored by measuring the water content or by other analytical methods.

Distillation: Excess acetic acid and water are removed from the crude product, often via a distillation process.

Purification: The PGDA may undergo further purification steps to achieve the desired purity level, which can include additional distillation, filtration, or other separation techniques.

Quality Control: The final product is tested to ensure it meets specific standards and specifications.

Storage and Packaging: The purified PGDA is then stored and packaged appropriately for distribution.

How can we handle your order?

step 1

We will communicate with you within 24 hours after you send an enquiry.

step 2

If you need sample testing, we will send samples within 5 days,≤50kg, Express delivery recommended, usually called as DDU service; delivery time 5-7 days. Door to door service.

step 3

If you need bulk goods after the sample test is qualified, we will ship the goods to the port and keep the samples within 6 days after the order is confirmed. Sea shipping recommended, usually called as FOB, CFR, or CIF service.delivery time 10-45 days. Port to port service.

step 4

After waiting for you to receive the goods, we will arrange professional staff to pay a return visit within 7 days.

1,2-Propylene Diacetate(PGDA)Technical

| Name | 1,2-Propylene diacetate |

| CAS | 623-84-7 |

| EINECS | 210-817-6 |

| Molecular Formula | C7H12O4 |

| Molar Mass | 160.17 |

| Density | 1.05g/mLat 25°C(lit.) |

| Melting Point | -31 °C |

| Boling Point | 191°C(lit.) |

| Flash Point | 187°F |

| JECFA Number | 1976 |

| Water Solubility | 76g/L at 20℃ |

| Solubility | 90g/l |

| Vapor Presure | <1 hPa (20 °C) |

| Appearance | clear liquid |

| Color | Colorless to Almost colorless |

| Odor | at 100.00 %. fruity acetic |

| BRN | 1768914 |

| Storage Condition | Store below +30°C. |

| Explosive Limit | 2.8-12.7%(V) |

| Refractive Index | n20/D 1.414(lit.) |

| LogP | 0.82 at 25℃ |

| Toxicity | LD50 orally in Rabbit: 13530 mg/kg |

| HS Code | 29153990 |

| Acid Number | ≤0.015 |

| Physical and Chemical Properties | 1, 2-propylene glycol diacetate is a colorless to light yellow liquid with low volatility and a slight sweet taste. It is soluble in organic solvents such as alcohols and ethers, but insoluble in water. |

Characteristics of PGDA

1,2-Propylene diacetate( PGDA) is a relatively new chemical, and its emergence solves many problems compared to the previous production

The product is more environmentally friendly, the purity is better, and a product is available because it has its own unique characteristics.

- Strong solubility, it is a strong solvent of alkyd resin, acrylic resin, polyester resin, nitrocellulose resin, chlorinated resin, PU curing agent, etc. Water-based resin synthesis, water-based curing agent diluent (good hydrophobicity, poor reactivity with NCO) and TEXANOL ester 12 used in water-based coatings.

- Non-toxic and low taste contains a light mint smell, in terms of the use of prohibited substances and harmful substance limits in line with the European Union RoHS Directive 2002/95/EC redraft Directive 2011/65/EU Appendix II limits requirements. PGDA has been listed in the United States Pharmacopeia NF XVI. It can partially replace high boiling point and high taste solvents such as cyclohexanone, isophorone, CAC, PMA and ethylene glycol monobutyl ether.

- It can completely replace DBE, has stronger dissolution force than DBE, and has the characteristics of improving the leveling and adjusting the drying speed of the paint film.

Usage: Use 3-5% in the paint formula; The proportion of summer diluent used is 10-15%.

Volatilization rate comparison: butyl acetate =1.0, PGDA=0.04, DBE=0.025, EGDA=0.05.

PGDA has the advantages of narrow distillation range, stable composition, stronger dissolution force and lighter odor, and is suitable for waterborne paint film forming additives.

Application of PGDA

1,2-Propyleneglycol diacetate (PGDA) is a versatile solvent with a wide range of applications due to its favorable properties such as a high boiling point, low toxicity, and environmental friendliness. Here are some of the primary applications of PGDA:

| Application Area | Use of PGDA | Function/Benefit |

| Ink and Adhesive | Replacement for various solvents in inks and adhesives | PGDA replaces isophorone 783, CAC, ethylene glycol monobutyl ether, propylene glycol ether ester solvents, cyclohexanone, diacetone alcohol (DAA), cresol, etc., due to its environmental safety and solvency. |

| Coating Film Additives | In can/coil coatings and as a film forming agent | Combines the properties of CAC, PMA, BCS, and CYC. Offers environmental friendliness, low odor, good leveling, and strong solubility. Enhances safety in storage and production due to high flash point. Improves gloss, fullness, and whiteness in topcoat paints. Prevents heat rash and dark bubble formation. |

| Water-based Curing Agents | As a diluent in water-based PU curing agents | Exhibits strong hydrophobicity and poor reactivity with NCO, enhancing fluidity and fullness of the film, and improves thickness of the non-foaming film. |

| Diluent for Various Resins | Replacing DBE as a solvent for multiple resins | Superior solubility compared to DBE. Effective in dissolving alkyd, acrylic, polyester, nitrocellulose, and chloro-acetate resins. Offers high boiling point, narrow distillation range, low-odor, and environmental protection. |

| Industrial Cleaning Agents | As a solvent in industrial cleaning | Effective in cleaning electronic and precision equipment |

| Pharmaceuticals | Solvent for active ingredients | Non-toxic and safe for use in sensitive applications |

| Cosmetics | In cosmetic formulations | Ensures safety and efficacy of cosmetic products |

| Food Industry | In flavor extracts and food additives | Safe for use in food-related applications |

| Resin Synthesis | For water-based resin synthesis | Enhances resin properties, useful in various industrial products |

| Electronics | In PCB circuit board ink and electronic ink | Improves print quality and durability on circuit boards |

| Cleaning and Paint Removal | Used as a cleaning agent and paint remover | Effective in removing paints and cleaning surfaces |

| Plastics Industry | Cellulose acetate plasticizer | Improves flexibility and durability of plastic products |

| Organic Synthesis | As an intermediate | Used in the synthesis of various organic compounds |

The wide-ranging applications of PGDA in various industries underscore its importance as a solvent and an agent that enhances the performance of products in coatings, inks, adhesives, and more. Its growing popularity is also partly due to the increasing focus on environmentally friendly and safer chemical products in industrial processes.

If you have specific questions or need more detailed information about any of these applications, feel free to ask. I’m here to provide the insights you need for your business considerations.

REQUEST A QUOTE FOR MORE DETAILS

Three Generations of High Boiling Point Environmental Solvent Comparison

| Generation | Solvent Type | Key Characteristics | Applications |

|---|---|---|---|

| First | Organic Dibasic Acid Ester Mixtures | Can completely or partially replace solvents like cyclohexanone, ethylene glycol ether acetate, etc. Improves coating leveling and adjusts drying speed. | Used in steel, wood, container, food packaging, automobile coatings, enameled wire coatings, and baking paints. |

| Second | Ethylene Glycol Diacetate(EGDA) | More environmentally friendly than the first generation. Offers similar replacement functions for high-boiling point odor solvents. | Suitable for baking paint, nitrocellulose paint, coil steel paint, cellulose ester, fluorescent paint, iron printing paint, automotive paint, wood paint, insulation paint, and electrical appliances and metal furniture paint. |

| Third | 1,2-Propylene Diacetate (PGDA) | Strong solubility, non-toxic, low odor, and more environmentally friendly than the first and second generations. | Ideal for alkyd resin, acrylic resin, polyester resin, nitrocotton resin, chlorinated resin, and PU curing agents. Functions as a superposition of the first two generations’ solvents. |

The Market Prospects of PGDA

In recent years, with the improvement of global environmental awareness and the rapid development of new material technologies, the market demand for PGDA has continued to grow. Especially in the field of industrial production, the application range of PGDA is more and more wide, and the market prospect is very broad. According to market research institutions, the global market size of PGDA is expected to exceed 10 billion yuan in the next few years.

At the same time, with the progress of science and technology, the production technology of PGDA is also constantly improving, and green and environmentally friendly PGDA will become the focus of research and development in the future. This will also drive the entire chemical industry to become more sustainable and environmentally friendly.

In general, as an important organic chemical, PGDA has a wide range of application prospects and development potential in the industrial and chemical industry. It is believed that with the continuous progress of science and technology and the continuous expansion of the market, PGDA will bloom more dazzling light in the future development.

Why Us

As a supplier of 1,2-Propylene diacetate (PGDA), we are proud to highlight several compelling reasons for our product advantages:

- Quality and Purity: Our PGDA boasts a purity level of 99%, ensuring high efficacy and consistency in your applications. Each batch of our PGDA undergoes strict quality testing to ensure that it meets the high standards we have set. This includes testing for impurities, consistency in formulation, and ensuring that it aligns with industry specifications.

- Environmentally Friendly: With an increasing emphasis on sustainability, PGDA stands out as a more environmentally friendly option compared to many traditional solvents. It contributes to lower volatile organic compound (VOC) emissions, aligning with green manufacturing practices and regulatory compliance.

- Technical Support: Our team of experts is available to provide technical support and guidance, ensuring that our clients can maximize the benefits of our PGDA in their specific applications.

- Consistent Supply: We understand the importance of having a dependable solvent supplier. Our robust supply chain management ensures consistent product availability, helping you maintain uninterrupted operations.

- Regulatory Compliance: Our commitment to sustainability ensures that our PGDA not only meets but often exceeds environmental regulations, aiding your business in staying compliant with evolving standards.

- Innovative Solutions: Continuously seeking innovative applications and solutions for PGDA can position your company as a forward-thinking and valuable partner in various industries.

Choosing our PGDA means choosing a partner dedicated to your business’s success. We provide not just a solvent but a holistic solution, ensuring efficiency, quality, and compliance with environmental and safety standards.

Our Team

FAQs of 1,2-Propylene Diacetate(PGDA)

A1: As a supplier, we ensure our PGDA is of the quality with 99% purity, guaranteeing consistent performance and reliability for a wide range of industrial applications.

A2: Sure, we’re equipped to handle large-volume orders and guarantee consistent supply. Our robust production capabilities and efficient logistics network enable us to meet high demand while maintaining the quality and reliability that our customers expect.

A3: We employ rigorous batch testing and quality control processes to guarantee consistent quality in every shipment.

A4: Our minimum order quantity is 1 ton, catering to both large and small-scale needs.

A5: Absolutely. We offer 100g-200g samples, with the client only covering shipping costs.

A6: Standard lead times are approximately 2-4 weeks, varying based on order size and destination.

A7: Our standard payment terms include a 30% advance and the balance against delivery, but terms can be negotiated for long-term partnerships.

A8: Yes, we offer comprehensive after-sales support, addressing any post-purchase queries or concerns.

A9: As a supplier, in order to provide you with an accurate quote for your product, please inform us of the quantity you require, the required purity specifications, any specific packaging needs, your shipping location, and whether your application requires any customization requirements or certifications.