Polylactic Acid (PLA)

----Unbelievable Transformation: From Corn and Straw to Revolutionary Pellets That Rival Plastic!

Corn

Polylactic Acid (PLA)

The Superior Performance of PLA

Eapearl’s PLA (Polylactic Acid) is an innovative, eco-friendly thermoplastic made from renewable sources like corn and straw. It features superior strength, clarity, and biodegradability, making it ideal for various applications in packaging, 3D printing, and medical devices. PLA’s versatility, safety, and environmental benefits position it as a sustainable alternative to traditional plastics.

Application of Polylactic Acid (PLA)

1. Green Fiber Applications

Substitute for Petroleum-based Fibers (PET, PBT, PTT, etc.): PLA fibers are used to create fabrics that are naturally skin-friendly, antibacterial, and anti-mite due to their weak acidity, similar to human skin.

Advantages: Fabrics made from PLA fibers offer excellent drape, moisture-wicking, breathability, and a silky, lustrous finish. They also provide effective UV protection, making them ideal for underwear, sportswear, leisurewear, and bedding products.

2. Green Plastic Applications

Alternative to Petroleum Plastics (PE, PP, PVC, etc.): PLA is used to manufacture household plastics (cups, plates, containers, bottles), industrial plastics (interior components for vehicles, ships, aircraft, and appliance casings), thin plastic films, and medical materials (surgical sutures, bone pins).

Benefits: PLA is safe, non-toxic, biocompatible, and offers excellent antibacterial and mold resistance properties. It’s also a primary material for 3D printing.

Significance: Annually, over 67 million tons of plastics are used in global food packaging, presenting a huge opportunity for PLA as a substitute.

| Property | PLA | PS | PET | PP |

| Tensile Strength (MPa) | 50 | 45.5 | 58.6 | 35.9 |

| Elongation at Break (%) | 30 | 1.4 | 5.5 | 350 |

| Tensile Modulus (GPa) | 3.45 | 3.03 | 3.45 | 1.31 |

| Izod Impact (J/m) | 16 | 21.4 | 26.7 | 48.1 |

| Glass Transition Temp (℃) | 57-62 | 102 | 74 | -20 |

| Melting Point (℃) | 135-175 | N/A | 270 | 165 |

| Density (g/cc) | 1.25 | 1.05 | 1.35 | 0.9 |

3. Mechanical Properties of PLA

Comparable to Polystyrene (PS): PLA exhibits similar mechanical properties to PS, making it a versatile alternative.

4. Applications in Green Boards and Bio-based Polyurethane

Bio-based Polyurethane: PLA polyols are used to produce bio-based polyurethanes, applicable in synthetic leather, oil films, rigid and flexible foams.

Green Boards: Utilizing straw to produce PLA, about 4 tons of straw yield 1 ton of PLA + 1 ton of wood-plastic material. Wood-plastic materials made with PLA as a binder are free from Bisphenol A and formaldehyde (urea-formaldehyde resins, phenol-formaldehyde resins), widely used in interior and exterior decoration, furniture manufacturing, and office furniture.

5. Bi-axially Oriented PLA Film (BOPLA)

Enhanced Properties: The bi-axial stretching of PLA film increases polymer crystallinity and refinement, enhancing the mechanical strength and transparency of BOPLA films.

Applications: Used in various packaging applications like cigarette film, overwrapping film, tape, protective film, twist wrap packaging, shrink packaging, refrigerated anti-fog and UV-resistant fresh-keeping packaging, and in combinations like BOPLA aluminized, aluminum-plastic, paper-plastic, and plastic-plastic composites.

Market Potential: BOPLA has been successfully mass-produced, with the Chinese downstream application market alone exceeding 10 million tons per year.

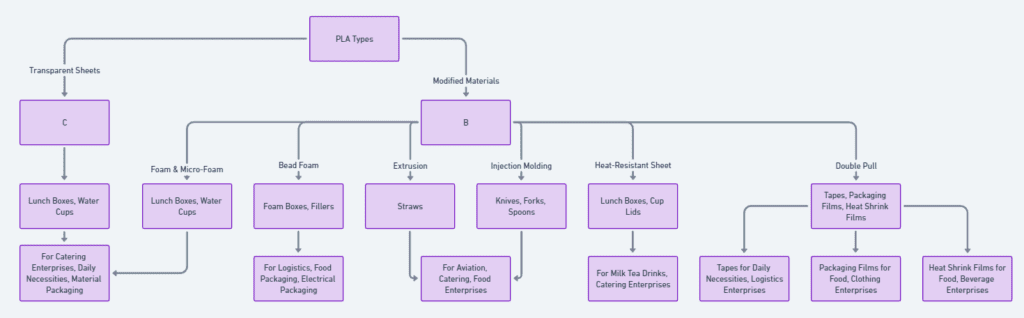

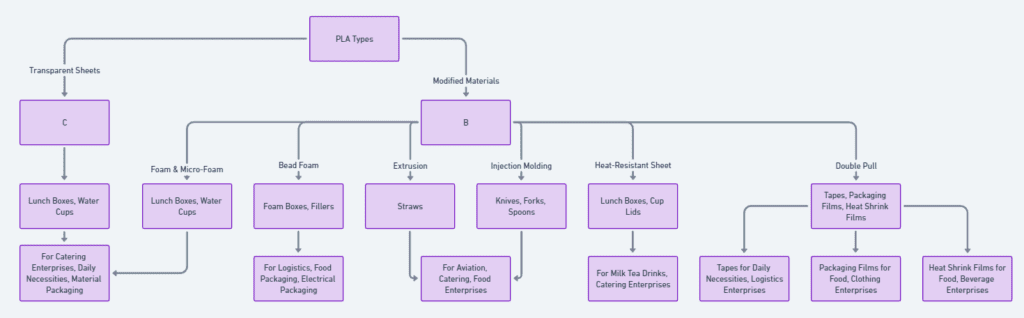

End-products Derived From PLA

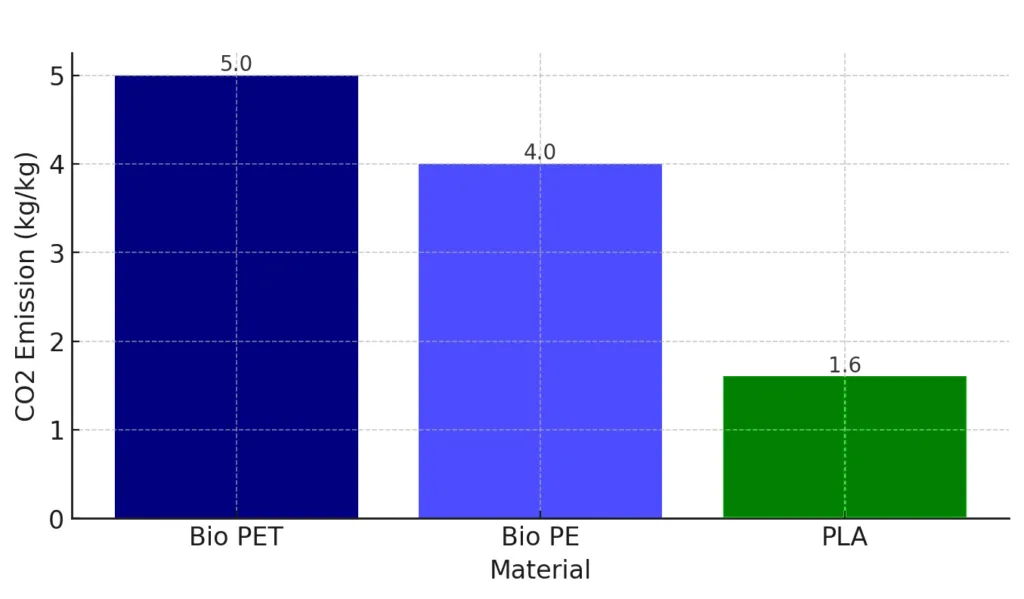

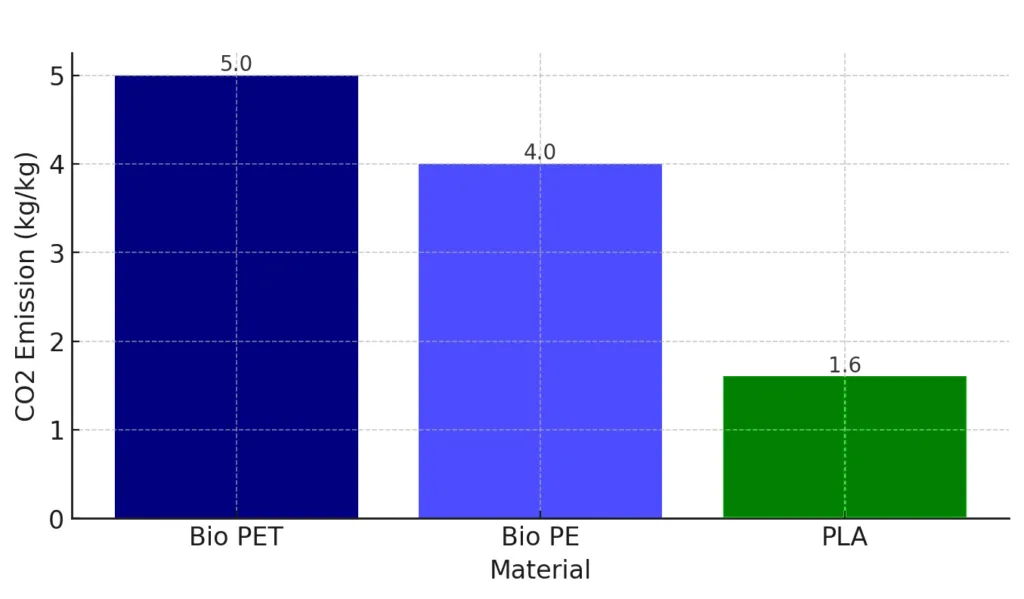

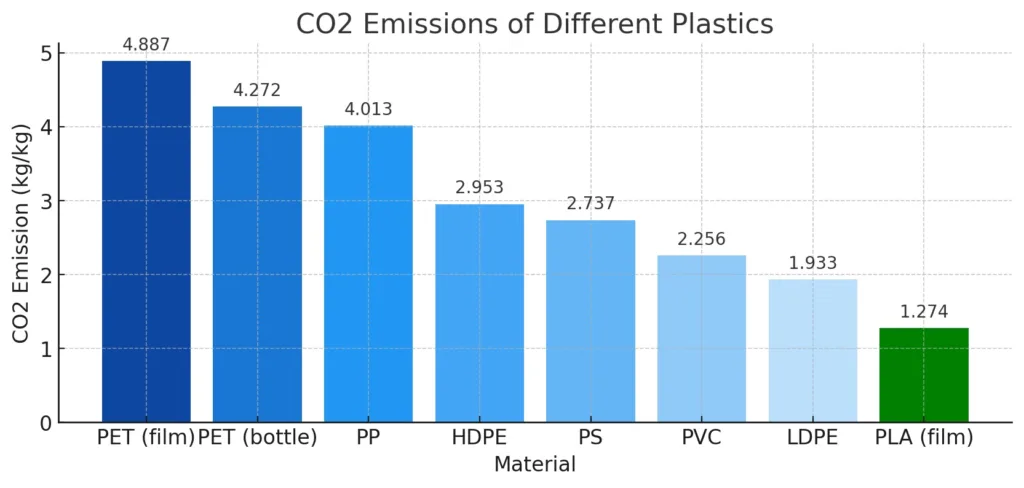

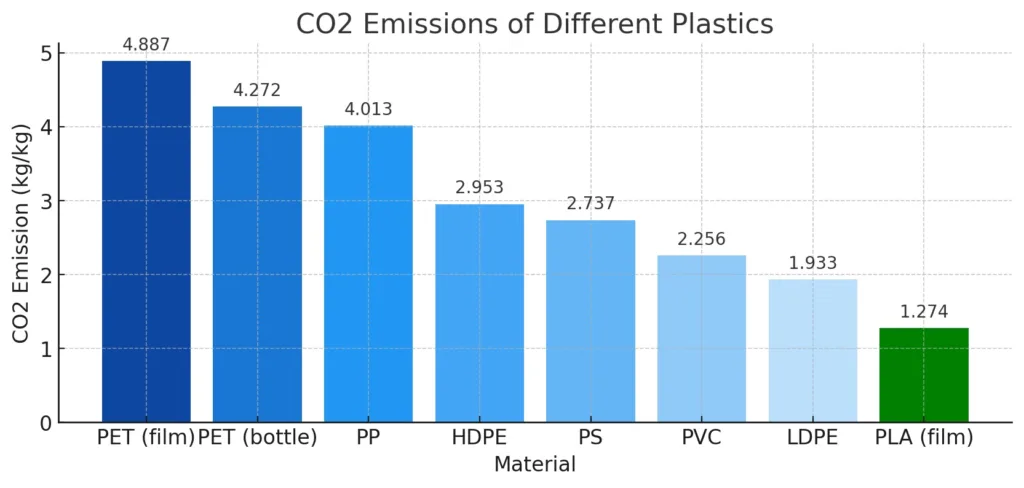

Carbon emissions of PLA

Carbohydrate Usage in Bioplastics (Sugar Content per Kilogram of Plastic in Kilograms)

Compared to traditional petrochemical-based polymers, PLA boasts reliable biosafety and biodegradability. Being derived from biomass, PLA significantly contributes to carbon reduction, slashing carbon emissions by over 68% compared to conventional fossil-based plastics.

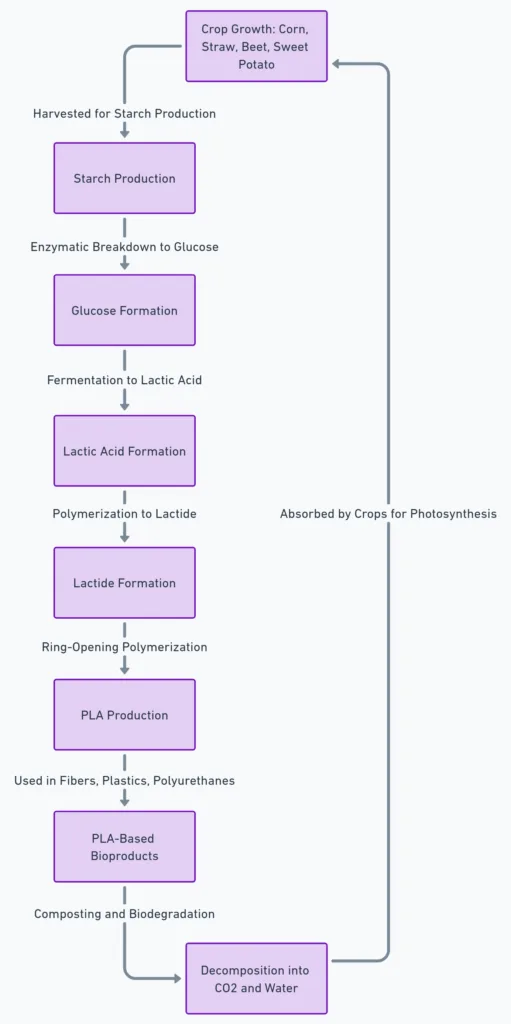

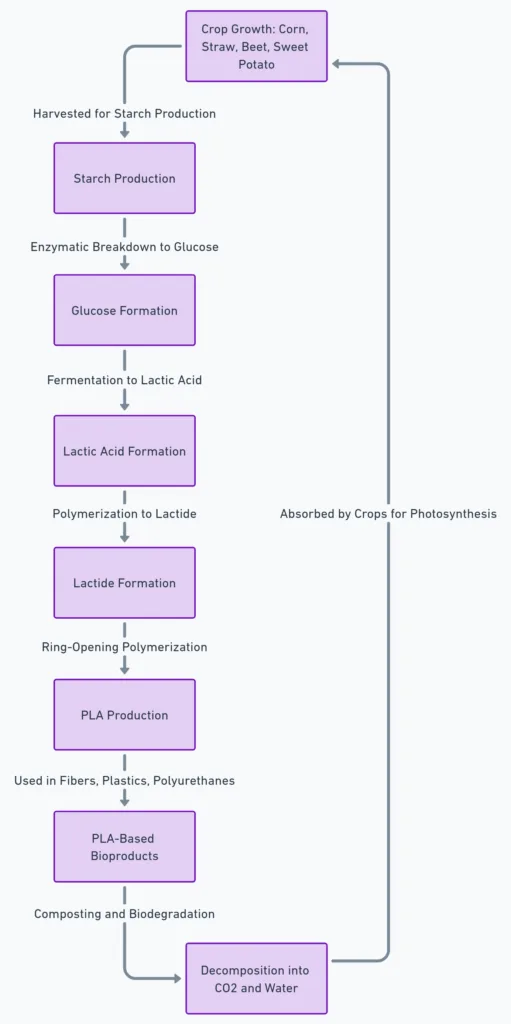

PLA's Circular Lifecycle

Polylactic Acid (PLA) production embodies a sustainable cycle, beginning with the growth of crops such as corn, straw, sugar beets, and sweet potatoes. These plants are harvested and processed into starch, which is then enzymatically broken down into glucose. The glucose undergoes fermentation to produce lactic acid, a crucial building block. This lactic acid is polymerized to form lactide and then through ring-opening polymerization, it is transformed into PLA.

PLA serves as the foundation for creating a variety of biologically-derived materials, including fibers, plastics, and polyurethanes. These innovative materials are not just environmentally friendly in their creation but also in their disposal. Post-use, PLA products can be composted, breaking down into carbon dioxide and water, which are then reabsorbed by plants through photosynthesis, thus completing the cycle and minimizing environmental impact.

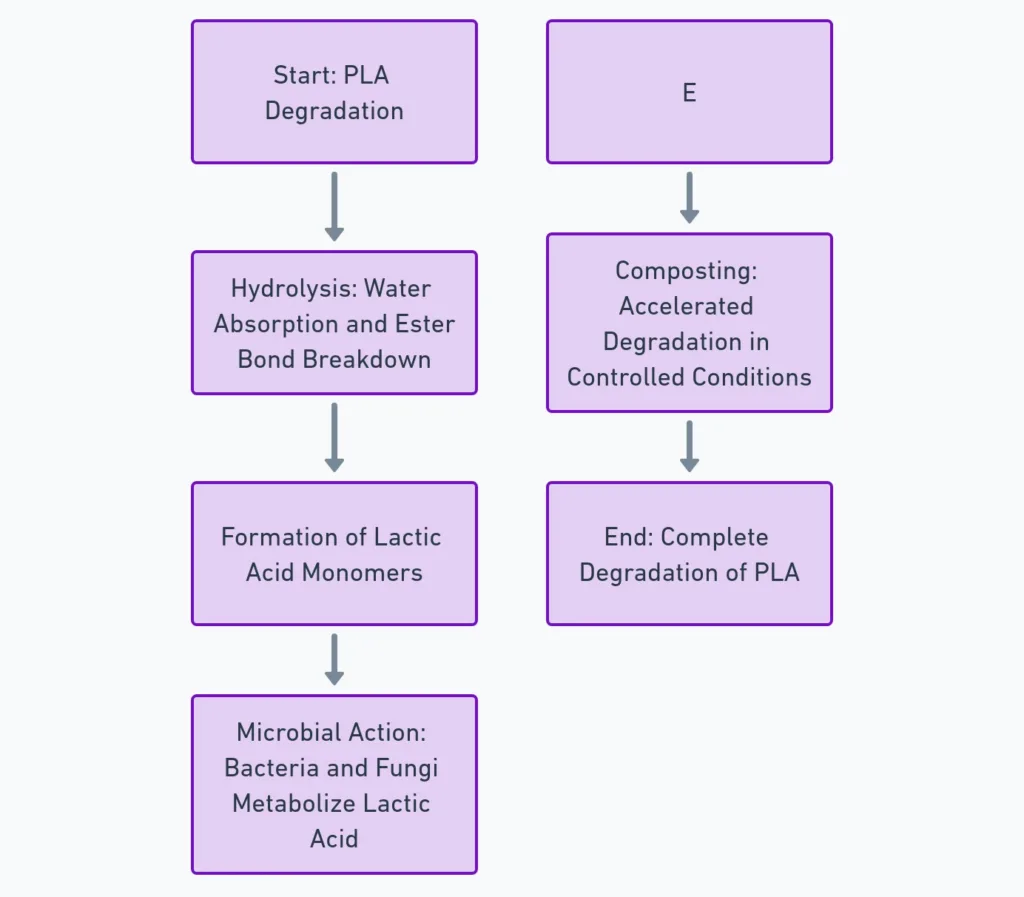

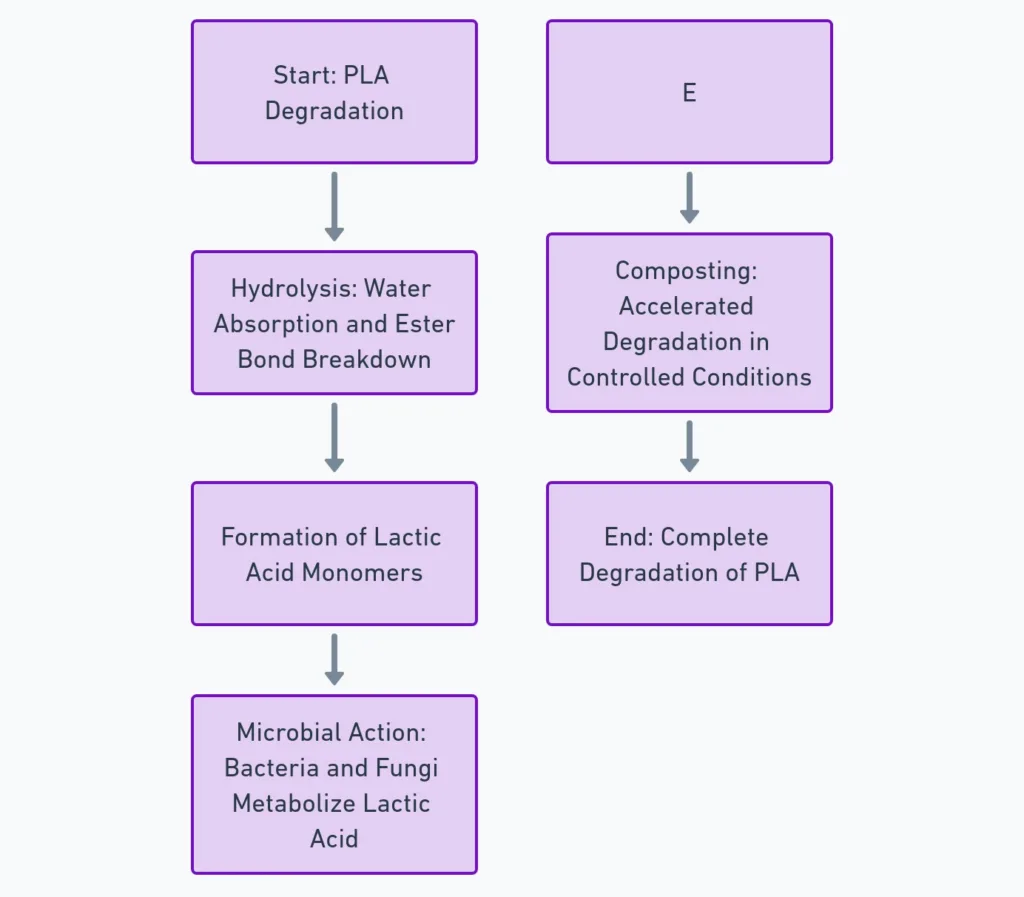

Polylactic Acid (PLA) Degradation

Polylactic Acid (PLA) degrades primarily through a hydrolysis process. Here is a brief overview of the degradation mechanism:

Hydrolysis: PLA degradation begins with the absorption of water. The presence of water causes the ester bonds in the PLA polymer to hydrolyze, breaking the long polymer chains into smaller molecules, which are lactic acid monomers.

Microbial Action: Once the polymer has been sufficiently broken down into smaller lactic acid units, naturally occurring microbes in the environment, such as bacteria and fungi, can metabolize these smaller molecules.

Biodegradation: The microbial process converts the lactic acid into carbon dioxide (CO2) and water (H2O) in aerobic conditions, or into methane (CH4) in anaerobic conditions like those found in landfills.

Composting: PLA can also be industrially composted, where controlled conditions of temperature and humidity accelerate the hydrolysis and microbial digestion, resulting in a faster degradation process.

PLA Packing Instruction

| PA Packaging | Capacity | 20GP | 40GP |

| Bag | 25kgs/bag | total 800 bags, Net 20 Tons | total 1040 bags, Net26 Tons |

| Ton Bag | 850kgs/bag | total 20 bags, Net 17 Tons | total 24-26 bags, Net20.4-22.1 Tons |

| Ton Bag | 900kgs/bag | total 20 bags, Net 18 Tons | total 24-26 bags, Net 21.6-23.4 Tons |

| Ton Bag | 1 tons/bag | total 20 Ton bags, Net 20 Tons | total 24-26 Ton bags, Net 24-26 Tons |

PLA Product Specifications Comparative Chart

| Item | FY201 | FY202 | FY204 | FY401 | FY402 | FY404 | FY601 | FY602 | FY604 | FY801 | FY802 | FY804 |

| Appearance | Trans parent/ Trans lucent | Trans parent/ Trans lucent | Trans parent/ Trans lucent | Trans parent/ Trans lucent | Trans parent/ Trans lucent | Trans parent/ Trans lucent | Trans parent/ Trans lucent | Trans parent/ Trans lucent | Trans parent/ Trans lucent | Trans parent/ Trans lucent | Trans parent/ Trans lucent | Trans parent/ Trans lucent |

| Density (g/cm³) | 1.24 | 1.24 | 1.24 | 1.24 | 1.24 | 1.24 | 1.24 | 1.24 | 1.24 | 1.24 | 1.24 | 1.24 |

| Moisture (%) | ≤0.04 | ≤0.04 | ≤0.04 | ≤0.04 | ≤0.04 | ≤0.04 | ≤0.04 | ≤0.04 | ≤0.04 | ≤0.04 | ≤0.04 | ≤0.04 |

| Monomer Content (%) | ≤0.3 | ≤0.3 | ≤0.3 | ≤0.3 | ≤0.3 | ≤0.3 | ≤0.3 | ≤0.3 | ≤0.3 | ≤0.3 | ≤0.3 | ≤0.3 |

| MFR (190°C/2.16kg) | 30 | 30 | 18 | 18 | 18 | 18 | 9 | 9 | 9 | 4 | 4 | 4 |

| D-content (%) | <1 | 2 | 4 | <1 | 2 | 4 | <1 | 2 | 4 | <1 | 2 | 4 |

| Melting Point (°C) | 175 | 155 | 165 | 175 | 155 | 165 | 175 | 155 | 165 | 175 | 155 | 165 |

| Glass Transition Temp (°C) | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 60 |

| Tensile Strength (MPa) | 50 | 50 | 45 | 50 | 50 | 45 | 50 | 50 | 45 | 50 | 50 | 45 |

| Elongation at Break (%) | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 |

Qualifications of Eapearl Polylactic Acid (PLA)

ISO9001

ISO14001

DIN Geprüft

BPI Certified

EU

FDA

SGS

NEQSI

Reach

FAQs of Polylactic Acid (PLA)

A1: PLA, or Polylactic Acid, is a biodegradable and bioactive thermoplastic made from renewable resources like corn starch, sugarcane, or cassava. It’s an eco-friendly alternative to petroleum-based plastics.

A2: PLA has a competitive strength comparable to conventional plastics like PET and can be engineered for enhanced durability for specific applications. However, it can be more brittle without modification.

A3: Yes, PLA is generally recognized as safe for food contact. It’s widely used for food packaging and service products and complies with food safety regulations, such as those set by the FDA.

A4: Modified PLA has been engineered to withstand higher temperatures, making it suitable for applications such as microwaveable tableware. While standard PLA may not tolerate high heat, these specialized blends can maintain their integrity when heated in a microwave oven.

A5: PLA is biodegradable under industrial composting conditions and is made from renewable resources, reducing the carbon footprint and dependency on fossil resources.

A6: PLA products should be composted in industrial facilities where they can properly break down. They are not suitable for traditional recycling streams unless specifically stated.

A7: PLA products have a good shelf life and can last as long as traditional plastics when stored properly, away from heat and direct sunlight.

A8: Yes, PLA comes in various grades suitable for different manufacturing processes like injection molding, extrusion, and thermoforming.

A9: Absolutely, PLA is one of the most popular materials for 3D printing due to its ease of use, good surface quality, and low warping characteristics.

A10: Certifications to look for include compostability standards like ASTM D6400 or EN 13432, food contact safety certifications like FDA compliance, and potentially, biobased content certifications.

A11: The cost of PLA is competitive and often comparable to that of other plastics, with the added value of being eco-friendly, which can be a significant factor for consumers.

A12: Yes, PLA can be blended with other materials or additives to tailor its properties, such as impact resistance or flexibility, to meet specific product requirements.