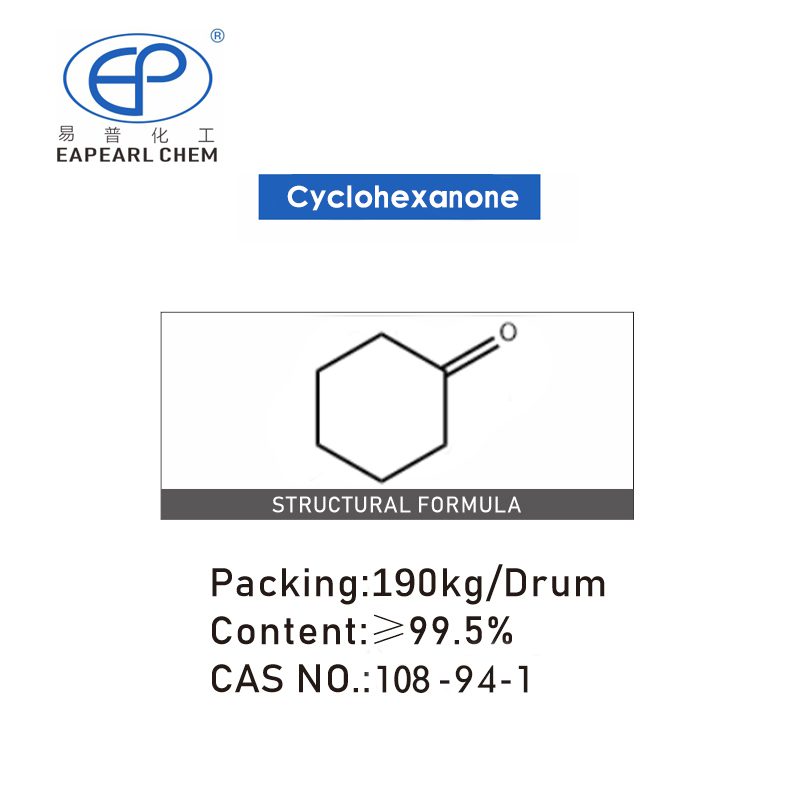

Cyclohexanone (CYC)

| Product Name | Cyclohexanone |

| Synonyms: | Anon Hexanon Hytrol O hexan-2-one Cicloesanone Cyclohexanone Cykloheksanon PIMELIC KETONE |

| CAS | 108-94-1 |

What Cyclohexanone (CYC) Is

Cyclohexanone is an organic compound with the molecular formula C6H10O. It is a colorless, oily liquid with a slightly pungent odor, resembling that of acetone or peppermint, though less intense. This compound is a cyclic ketone with a six-carbon ring structure and a ketone functional group (a carbon double-bonded to oxygen) at one of its positions.

Properties

Physical Properties: Cyclohexanone is a relatively volatile liquid at room temperature with a moderate boiling point. It is miscible with common organic solvents, such as alcohols, ketones, and ethers, but has limited solubility in water.

Chemical Properties: The ketone group in cyclohexanone makes it a reactive compound capable of forming various chemical derivatives. It can undergo condensation reactions to form polymers and is a precursor to nylon through the production of adipic acid and hexamethylenediamine. Its reactivity also includes forming oximes and hydrazones upon reaction with hydroxylamine and hydrazine.

Synthesis: Industrially, cyclohexanone is produced by the oxidation of cyclohexane in air, typically using a cobalt catalyst. The phenol’s hydrogenation can also be obtained in the presence of a catalyst such as palladium on carbon.

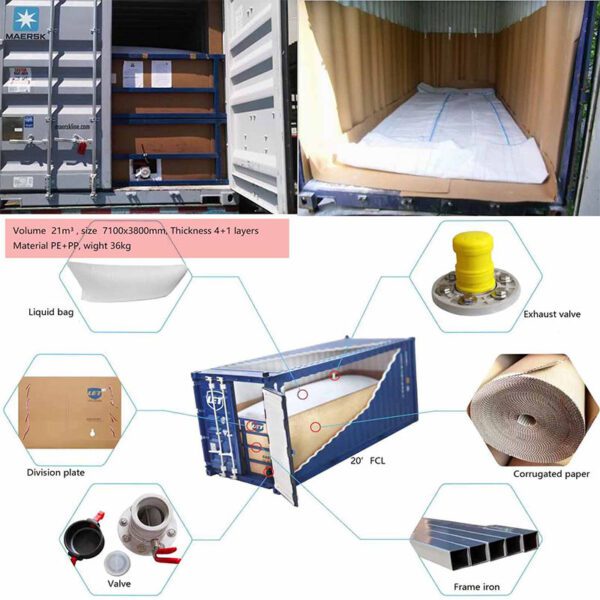

Cyclohexanone Packaging Information

Metal Drum

IBC Drum

Flexible Bag

ISO Tank

| Cyclohexanone packaging | Capacity | 20GP | 40GP |

| drum | 190 kg /drum | total 80 drums, Net 15.2 ton | total 120 drums, Net 22.8 ton |

| IBC drum | 1000 kg /IBC | total 20 IBC, Net 20 ton | total 24 IBC, Net 24 ton |

| ISO Tank | 23 ton /ISO Tank | 1 ISO Tank, Net 23 ton | N/A |

For Cyclohexanone, we welcome you to test and check the quality, if you need a sample please contact our sales team to discuss your sample requirements, we believe that our product quality is suitable for the specific application. We provide samples free of charge but the shipping cost will be borne by you.

What Cyclohexanone (CYC) Applications

Nylon Production:

- Adipic Acid Synthesis: Cyclohexanone is oxidized to produce adipic acid, a key monomer for making nylon 6,6 fibers and resins.

- Hexamethylenediamine Production: It also serves as a precursor in the production of hexamethylenediamine through amination, another monomer for nylon synthesis.

Solvent Applications:

- Paints and Coatings: It dissolves ingredients that are insoluble in water, facilitating the production of smooth, uniform coatings.

- Adhesives: Enhances the adhesion properties in glues and sealants for various industrial and consumer applications.

Pharmaceutical Industry:

- Synthesis of Drugs: Used as a solvent in synthesizing several drugs, affecting reactions, or purifying the final product.

- Hormone Production: Acts as a solvent or intermediate in producing synthetic hormones.

Pesticide Production:

- Herbicide Intermediates: Utilized in creating intermediates that are further processed into commercial herbicides.

- Pesticide Formulations: Used to dissolve active ingredients in pesticide formulations to enhance application effectiveness.

Film and Electronics:

- Electronic Component Manufacturing: Used as a solvent in cleaning and degreasing electronic components before assembly.

- Film Coating: Applied in producing specialty films used in photographic and electronic materials.

Perfumery and Cosmetics:

- Stabilizer: Helps stabilize volatile compounds in perfumes and cosmetics.

- Odorant Synthesis: Serves as an intermediate in synthesizing certain fragrance compounds.

Plasticizer Production:

- Flexibility Enhancement: Converts rigid polymers into flexible plastics for consumer products and packaging use.

Dye and Rubber Chemicals:

- Dye Manufacturing: Acts as a solvent in the dye manufacturing process for textiles and leathers.

- Rubber Adhesion Promoters: Improves rubber bonding to metal and other materials in the production of tires and industrial rubber goods.

Cleaning Agent:

- Industrial Cleaning: Used in industrial cleaning formulations for metal and machinery, effectively removing oils and residues.

Leather Industry:

- Degreasing: Removes excess fats from leather, improving the quality and durability of the final product.

- Shoe Polish: Incorporated into formulations to enhance shine and protective properties.

Textile Applications:

- Solvent Dyeing: Assists in solvent dyeing for synthetic fibers that don’t dye well with water.

- Blocking Agent: Used to secure areas of fabric to prevent the spread of dyes during the coloration process.

Chemical Intermediate:

- Synthesis of Other Chemicals: Serves as a critical building block for various chemical reactions, creating polymers, resins, and other industrial chemicals.

REQUEST A QUOTE FOR MORE DETAILS

How can we handle your order?

step 1

We will communicate with you within 24 hours after you send an enquiry.

step 2

If you need sample testing, we will send samples within 5 days,≤50kg, Express delivery recommended, usually called as DDU service; delivery time 5-7 days. Door to door service.

step 3

If you need bulk goods after the sample test is qualified, we will ship the goods to the port and keep the samples within 6 days after the order is confirmed. Sea shipping recommended, usually called as FOB, CFR, or CIF service.delivery time 10-45 days. Port to port service.

step 4

After waiting for you to receive the goods, we will arrange professional staff to pay a return visit within 7 days.

Preparation of Cyclohexanone (CYC)

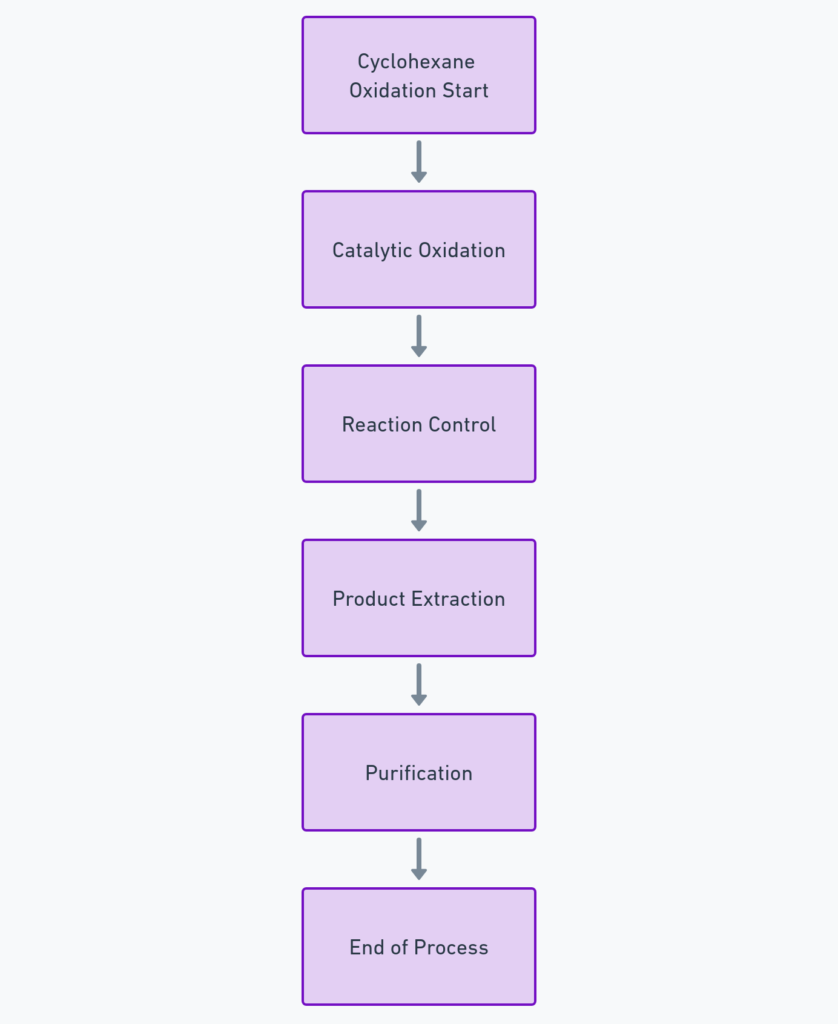

Oxidation of Cyclohexane

This is the most common method for producing cyclohexanone on an industrial scale.

- Catalytic Oxidation: Cyclohexane is oxidized using oxygen or air in a catalyst, typically cobalt or a mixture of cobalt and manganese. The process is conducted at elevated temperatures and pressures.

- Reaction Control: The reaction is exothermic and needs to be carefully controlled to prevent runaway reactions. Temperature control is achieved using a heat exchanger system.

- Product Extraction: The reaction mixture contains cyclohexanol, cyclohexanone, unreacted cyclohexane, and other by-products. The mixture is subjected to a series of distillation steps to separate the products.

- Purification: Cyclohexanone is purified further, if necessary, to achieve the desired purity level for specific applications.

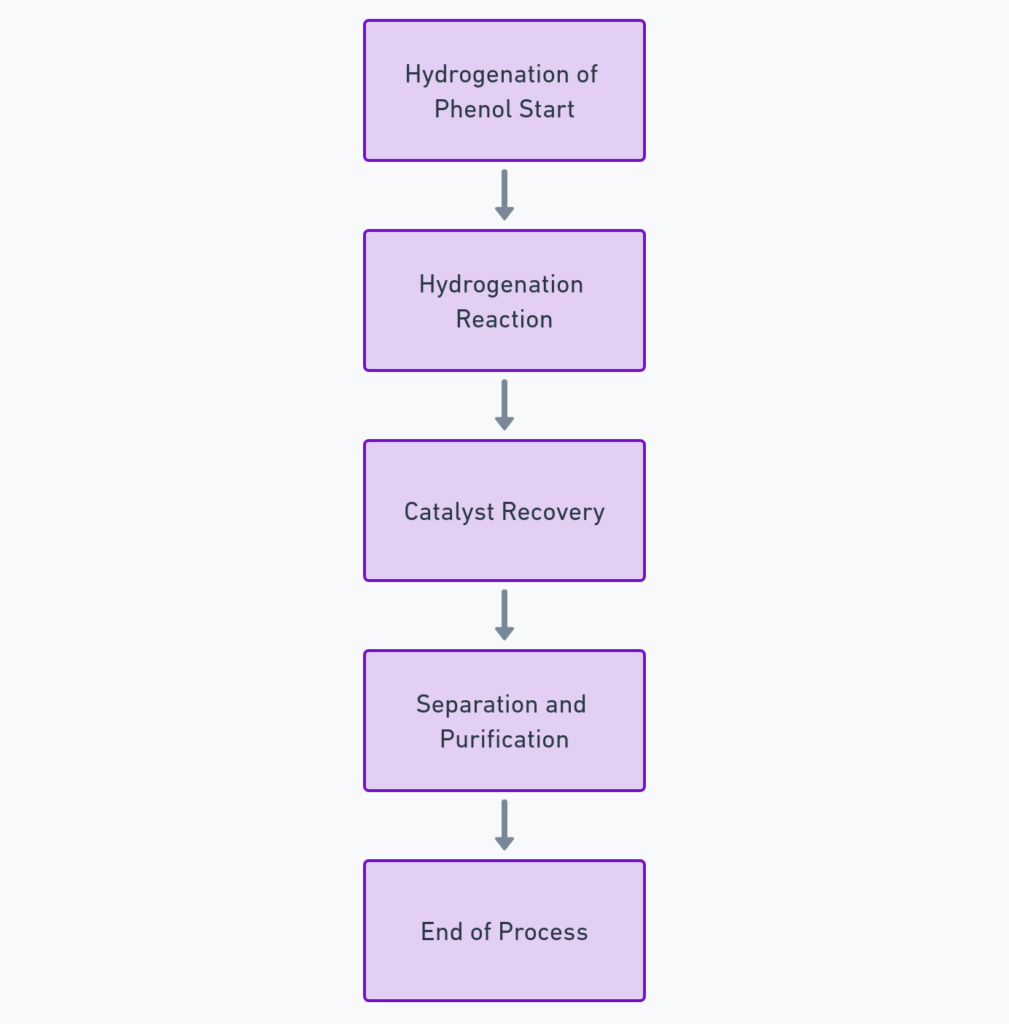

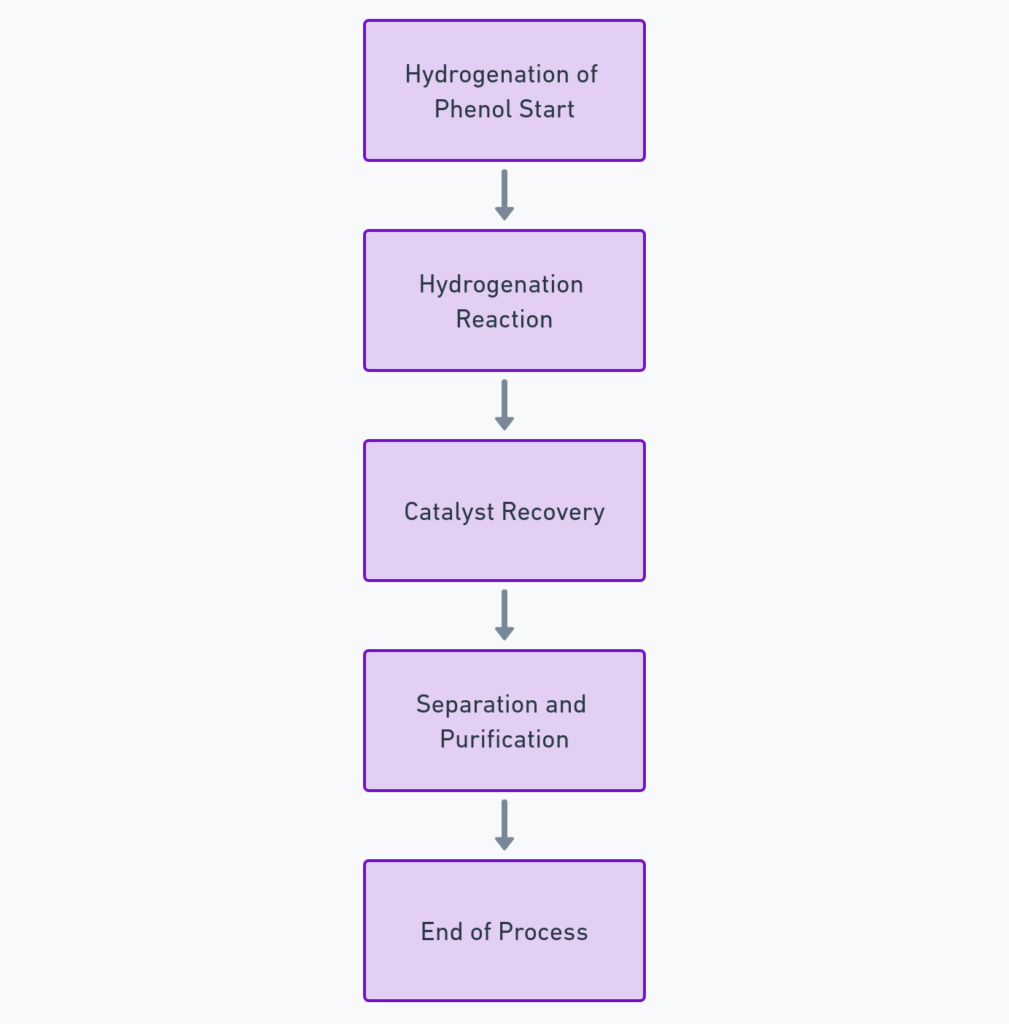

Hydrogenation of Phenol

This method is less common but is still used in some industrial settings.

- Hydrogenation Reaction: Phenol is hydrogenated in the presence of a catalyst such as palladium on carbon or nickel. The reaction is conducted under high pressure and at a temperature around 150-200°C.

- Catalyst Recovery: After the reaction, the mixture is filtered to recover the catalyst for reuse.

- Separation and Purification: The mixture is refined through distillation to separate the cyclohexanone from other products and by-products.

Cyclohexanone (CYC) Technical Data

| Name | Cyclohexanone |

| Molecular Formula | C6H10O |

| Molar Mass | 98.14 |

| Density | 0.947 g/mL at 25 °C (lit.) |

| Melting Point | -47 °C (lit.) |

| Boling Point | 155 °C (lit.) |

| Flash Point | 116°F |

| JECFA Number | 1100 |

| Water Solubility | 150 g/L (10 ºC) |

| Solubility | 90g/l |

| Vapor Presure | 3.4 mm Hg ( 20 °C) |

| Vapor Density | 3.4 (vs air) |

| Appearance | Liquid |

| Color | APHA: ≤10 |

| Odor | Like peppermint and acetone. |

| Exposure Limit | TLV-TWA 100 mg/m3 (25 ppm) (ACGIH);IDLH 5000 ppm (NIOSH). |

| Merck | 142726 |

| BRN | 385735 |

| pKa | 17(at 25℃) |

| PH | 7 (70g/l, H2O, 20℃) |

| Storage Condition | Store at +5°C to +30°C. |

| Stability | Stable. Combustible. Incompatible with strong oxidizing agents. |

| Explosive Limit | 1.1%, 100°F |

| Refractive Index | n20/D 1.450(lit.) |

| Physical and Chemical Properties | Colorless transparent liquid, with soil breath, the impurity is light yellow. |

| melting point -47 ℃ | |

| boiling point 155.6 ℃ | |

| relative density 0.947 | |

| refractive index 1.450 | |

| flash point 54 ℃ | |

| soluble in ethanol and ether |

Quality and Safety of Cyclohexanone

Uncompromised Quality Assurance

At Eapearl Chemicals, we understand that the cornerstone of our client’s manufacturing processes is the unwavering quality of our cyclohexanone. Our comprehensive quality assurance program encompasses:

- Rigorous Testing: Each batch of cyclohexanone undergoes stringent testing protocols, including Gas Chromatography (GC), Mass Spectrometry (MS), and Nuclear Magnetic Resonance (NMR) spectroscopy, to ensure product purity and consistency.

- Certified Excellence: We adhere to global industry standards and are proud to hold ISO 9001 certification, guaranteeing that our manufacturing processes meet the highest international quality criteria.

- Continuous Monitoring: Our in-process controls are designed to maintain the integrity of our product, with meticulous monitoring throughout the production cycle.

Robust Toxicology Data

Your safety is paramount. We provide detailed toxicology profiles that include:

- Material Safety Data Sheets (MSDS): Comprehensive data sheets offer guidance on handling, storage, and emergency measures, ensuring you have all the necessary information for safe usage.

- Exposure Control: Recommendations for appropriate personal protective equipment (PPE) and exposure limits are provided to protect your workforce and customers.

Stringent Safety Protocols

Safety is ingrained in our operational ethos. We enforce robust safety protocols that include the following:

- Controlled Environment: Cyclohexanone is handled in a controlled setting, strictly adhering to environmental health and safety (EHS) standards to prevent accidental release or exposure.

- Employee Training: Our personnel receive extensive training on safely handling chemicals, emergency response, and waste disposal to mitigate risks effectively.

- Regulatory Compliance: We stay abreast of and comply with all chemical safety regulations, ensuring our cyclohexanone meets and exceeds the regulatory requirements of each country we serve.

Through our unwavering commitment to quality and safety, Eapearl Chemicals remains a leader in providing high-grade cyclohexanone to the global market. Trust in our chemical solutions to empower your applications with the assurance of excellence and safety at the forefront.

REQUEST A QUOTE FOR MORE DETAILS

Download Center of Cyclohexanone

Cyclohexanone (CYC) Market Analysis

Overview

The Asia Pacific region, especially China, is pivotal in the cyclohexanone market, both as a significant consumer and producer. In 2022, the market size was approximately 3700 thousand tonnes, with an expected CAGR of 3.5% through 2032. Cyclohexanone’s primary applications, crucial in nylon manufacturing, include producing adipic acid and caprolactam and its use as a solvent in paints, adhesives, and pesticides. The automotive sector, notably in Asia, plays a significant role as an end-user, reflecting a substantial market share. Current market trends are moving towards sustainable production methods, influenced by the fluctuating costs of raw materials.

Market Dynamics

- Nylon Industry Growth: The market is driven by the expanding nylon industry, fueled by increased consumption in automotive, textiles, and electronics, particularly in emerging markets.

- Technological Advancements: Technological advancements have resulted in production efficiencies and quality improvements, making the market more competitive.

- Impact of Environmental Regulations: Stringent regulations push companies towards eco-friendly production methods, significantly impacting market dynamics.

Market Trends

- Sustainability Shift: A noticeable trend towards sustainable practices is evident, with companies exploring greener production methods.

- Asia-Pacific Expansion: Significant demand growth in the Asia-Pacific region, notably in China, has cemented its role as a critical market contributor.

- Raw Material Price Volatility: Fluctuating prices of essential raw materials like cyclohexane and phenol introduce market volatility.

Competitive Landscape

- Market Consolidation: The market shows moderate consolidation, with significant players dominating through strategic alliances, capacity expansions, and R&D.

- Role of Innovation: Innovation in production and applications is a primary differentiator, enabling market share growth and niche market penetration.

Future Outlook

- Demand Surge in Developing Nations: Industrialization in developing countries is set to spike demand, especially in the automotive and construction sectors.

- Bio-based Cyclohexanone Potential: Developing bio-based alternatives could reshape the market, aligning with global sustainability initiatives.

Conclusion

Eapearl Chemicals, with its focus on quality, innovation, and sustainability, is well-positioned to leverage these market dynamics, ensuring a reliable supply chain and growth partnership in the cyclohexanone market.

FAQs of Cyclohexanone (CYC)

Yes, purchasing cyclohexanone typically requires verification of qualifications and certificates, particularly for industrial use. Before purchasing, you should confirm:

- Business Credentials: Proof of your business’s legitimacy, such as a business license or registration.

- Safety Compliance: Evidence of your facility’s compliance with safety and environmental regulations, mainly if cyclohexanone is classified as a controlled substance in your region.

Cyclohexanone is primarily used to produce nylon, serving as a critical ingredient in making adipic acid and caprolactam. It’s also widely used as a solvent in manufacturing paints, adhesives, and pesticides.

While cyclohexanone is a stable compound, it should be handled carefully. It’s flammable and can be harmful if inhaled or ingested. Use personal protective equipment like gloves and goggles, and ensure good ventilation in the handling area.

Yes, cyclohexanone can be synthesized in a laboratory setting, commonly through cyclohexanol oxidation or phenol’s hydrogenation.

The purity of cyclohexanone is typically tested using methods like Gas Chromatography (GC) and Mass Spectrometry (MS), ensuring it meets industry standards for quality and consistency.

As a volatile organic compound (VOC), cyclohexanone can contribute to air pollution. Handling it involves measures to minimize emissions and adherence to environmental regulations for safe disposal.

Research is ongoing to find more sustainable, bio-based alternatives to cyclohexanone. However, as of now, the majority of cyclohexanone used industrially is derived from traditional methods.