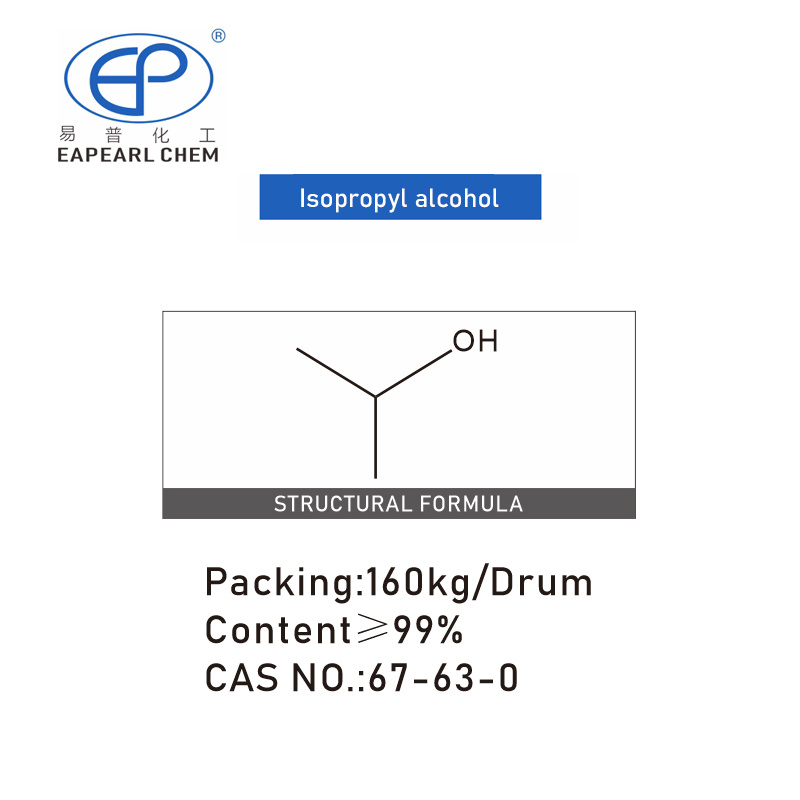

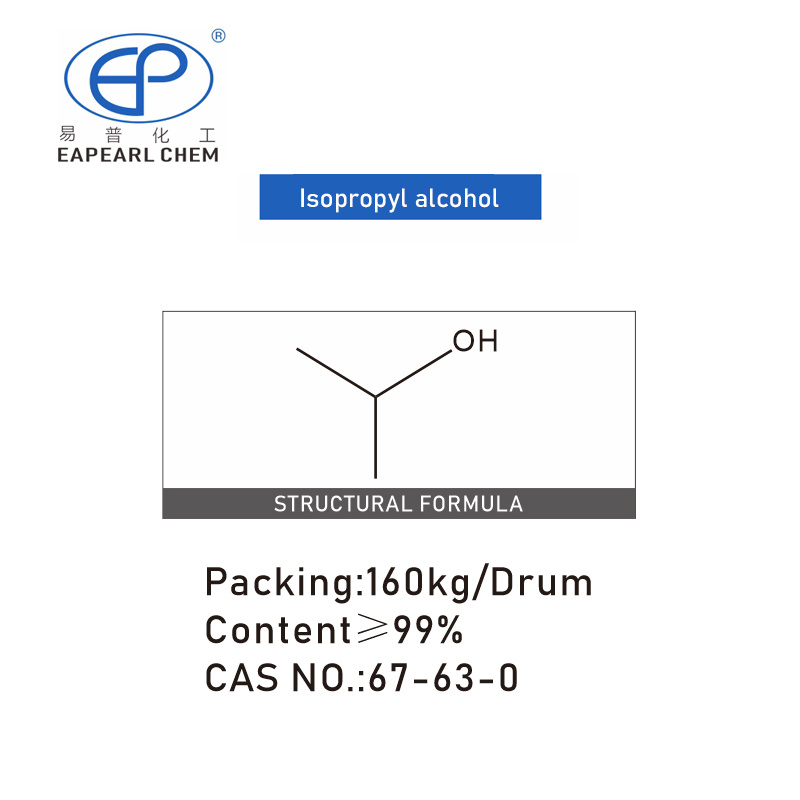

Isopropanol

Isopropanol, with the chemical formula C3H8O, is a three-carbon alcohol derived from ethylene or propylene hydration. This colorless liquid, possessing a pungent odor at room temperature, exhibits low boiling points and density, readily dissolving in water, alcohols, and ether solvents. As a polar solvent, isopropanol effectively dissolves various organic compounds, making it valuable in chemical synthesis. It serves as a crucial intermediate for esters, ethers, and alcohols. Widely utilized in industry, isopropanol acts as a versatile solvent and cleaning agent, showcasing its significance in diverse applications.

Table of Contents

| Name | Isopropanol |

| Synonyms | Isopropyl alcohol, IPA, Isopropanol, propan-1-ol, Isopropylalcohol, 2-PROPANOL (IPA), iso propyl alcohol, isopropanol anhydrous, Propan-2-ol-SPECIFIED |

| CAS | 67-63-0 |

| EINECS | 200-661-7 |

| Molecular Formula | C3H8O |

| Molar Mass | 60.1 |

| Purity | ≥99% |

| Packing | 160kg/drum |

In the world of cleaning and disinfection, nothing beats the killing power of top-quality isopropanol. If you’re searching for a solution that not only cleans but ensures your surfaces and equipment are germ-free, look no further. Our isopropanol is the gold standard, setting the bar high for purity, effectiveness, and safety.

Our commitment to quality is unparalleled. With Eapearl’s isopropanol, you’re guaranteed the highest purity standards. We go above and beyond industry regulations to deliver a product that stands out in performance and safety.

From delicate electronics to critical medical equipment, our isopropanol is your all-in-one solution. Versatile and powerful, it takes cleaning and disinfection to a whole new level. Discover why professionals across industries trust our isopropanol for their most demanding applications.

Safety is non-negotiable. Our isopropanol comes with clear, comprehensive labeling and safety instructions. Rest easy knowing you’re using a product that not only kills germs effectively but does so without compromising safety standards.

Isopropanol Packaging Information

| Isopropanol Packaging | Capacity | 20GP | 40GP |

| drum | 160 kg /drum | total 80 drums, Net 12.8 ton | total 152 drums, Net 24.32ton |

| IBC drum | 800 kg /IBC | total 20 IBC, Net 16 ton | total 32 IBC, Net 25.6 ton |

| ISO Tank | 18.5 ton /ISO Tank | 1 ISO Tank, Net 18.5 ton | N/A |

For isopropanol, we welcome you to test and check the quality, if you need a sample please contact our sales team to discuss your sample requirements, we believe that our product quality is suitable for the specific application. We provide samples free of charge but the shipping cost will be borne by you.

Isopropanol Application

Isopropanol is characterized by its versatile nature, stemming from its ability to act as a solvent, cleaning agent, and disinfectant. This compound boasts a distinctive, mildly sweet odor, and its physical state is that of a clear, colorless liquid. Notably, it exhibits a rapid evaporation rate, leaving minimal residue behind.

Isopropanol emerges as a multifaceted compound with a broad spectrum of applications. Its significance extends from industrial processes to everyday cleaning and disinfection, making it a cornerstone in various sectors.

Cleaning and Degreasing:

Isopropanol is a powerful solvent that excels in cleaning and degreasing applications. Its ability to dissolve oils, greases, and contaminants makes it indispensable in industrial settings. From machinery parts to intricate components, isopropanol ensures a thorough cleaning process without leaving any residue. It is particularly effective in removing stubborn residues that may accumulate in manufacturing processes.

Disinfection in Healthcare:

In healthcare environments, maintaining a sterile and sanitized atmosphere is paramount. Isopropanol plays a crucial role in disinfection protocols. Its rapid evaporation and broad-spectrum antimicrobial properties make it ideal for sanitizing medical instruments, surfaces, and equipment. Hospitals and healthcare facilities rely on isopropanol to prevent the spread of infections and ensure a safe environment for patients and healthcare professionals.

Electronics Cleaning:

Isopropanol is the go-to solution for cleaning electronic components. Its ability to dissolve dirt, dust, and flux residues without introducing moisture makes it a preferred choice. It is used in the cleaning of printed circuit boards (PCBs), connectors, and sensitive electronic devices. Isopropanol ensures the removal of contaminants without damaging delicate electronic components, making it an essential tool in electronics manufacturing and maintenance.

First Aid and Topical Antiseptic:

Isopropanol is a key ingredient in first aid applications, particularly in the formulation of rubbing alcohol. Its use as a first aid antiseptic involves cleaning wounds and preventing infection. The rapid evaporation of isopropanol ensures quick drying, making it suitable for topical application without prolonged exposure to moisture. It is a staple in first aid kits and healthcare settings for its reliability in promoting wound cleanliness.

Laboratory and Analytical Procedures:

Laboratories demand precision and cleanliness, and isopropanol meets these requirements seamlessly. Widely used for cleaning glassware, laboratory equipment, and surfaces, isopropanol ensures that experiments and analyses are conducted in an environment free from contaminants. Its high purity and volatility make it an indispensable tool in various laboratory processes, contributing to accurate and reliable results.

Pharmaceutical Manufacturing:

Isopropanol plays a vital role in pharmaceutical manufacturing as a versatile solvent. Its use in the extraction of active pharmaceutical ingredients ensures the production of medications with precise concentrations. Isopropanol’s compatibility with various pharmaceutical processes makes it a reliable component in the pharmaceutical industry, contributing to the formulation of high-quality medications.

Ink and Coating Industry:

Isopropanol serves as a valuable solvent in the ink and coating industry. Its ability to dissolve inks, paints, and coatings makes it an essential component in the formulation of printing inks and coatings. Isopropanol contributes to the stability and consistency of these products, ensuring optimal performance in printing and coating applications.

Eases Muscle Ache:

Isopropanol dries out skin to an extent that it is classified as a skin irritant, which is why you shouldn’t use too much of it if you’re using it as an antiseptic. It’s this same effect that makes ispropanol good for muscle ache.It’s often an ingredient in liniments simply because it irritates the skin, and therefore increases blood flow in that part of your body. In turn, this improved blood circulation eases muscle ache and inflammation.

Nail Polish Remover:

Isopropanol is a common ingredient in nail polish removers. Its role involves efficiently dissolving nail polish without causing excessive dryness to the nails. The inclusion of isopropanol in nail polish removers ensures an effective and user-friendly product in the cosmetics industry, contributing to the ease of nail care.

Deicing Agent:

Isopropanol’s low freezing point and ability to melt ice make it a valuable deicing agent, particularly in the aviation industry. Used for deicing aircraft surfaces, isopropanol efficiently removes ice and prevents its formation. Its effectiveness in extreme temperatures contributes to the safety and operational efficiency of aircraft during adverse weather conditions.

These detailed descriptions highlight the specific roles and benefits of isopropanol in various applications, showcasing its versatility and significance across diverse industries. If you have other specific isopropanol application questions, please contact us.

REQUEST A QUOTE FOR MORE DETAILS

Technical of Isopropanol

| Name | Isopropanol |

| Synonyms | Isopropyl alcohol, IPA, Isopropanol, propan-1-ol, Isopropylalcohol, 2-PROPANOL (IPA), iso propyl alcohol, isopropanol anhydrous, Propan-2-ol-SPECIFIED |

| CAS | 67-63-0 |

| EINECS | 200-661-7 |

| Molecular Formula | C3H8O |

| Molar Mass | 60.1 |

| Density | 0.785g/mLat 25°C(lit.) |

| Melting Point | -89.5 °C |

| Boling Point | 82°C(lit.) |

| Flash Point | 53°F |

| JECFA Number | 277 |

| Water Solubility | miscible |

| Solubility | water: soluble (completely) |

| Vapor Presure | 33 mm Hg ( 20 °C) |

| Vapor Density | 2.1 (vs air) |

| Appearance | Low Melting Solid |

| Specific Gravity | approximate 0.785(20/20℃)(Ph.Eur.) |

| Color | colorless |

| Odor | Like ethyl alcohol; sharp, somewhat unpleasant; characteristic mild alcoholic; nonresidual. |

| Exposure Limit | TLV-TWA 980 mg/m3 (400 ppm); STEL 1225 mg/m3 (500 ppm) (ACGIH); IDLH 12,000 ppm (NIOSH). |

| Maximum wavelength(λmax) | [‘λ: 260 nm Amax: 0.02’,, ‘λ: 280 nm Amax: 0.01’] |

| Merck | 145,208 |

| BRN | 635639 |

| pKa | 17.1(at 25℃) |

| Storage Condition | Store at +5°C to +30°C. |

| Explosive Limit | 2-13.4%(V) |

| Refractive Index | n20/D 1.377(lit.) |

| LogP | 0.05 |

| Physical and Chemical Properties | Character: colorless transparent flammable liquid with ethanol-like odor. |

| melting point -88.5 ℃ | |

| boiling point 82.45 ℃ | |

| freezing point -89.5 ℃ | |

| relative density 0.7855 | |

| refractive index 1.3772 | |

| solubility in water, ethanol, ether and chloroform were miscible. | |

| HS Code | 2905 12 00 |

Downloadable Documents about Isopropanol

REQUEST A QUOTE FOR MORE DETAILS

Isopropanol Production

In 1920, Isopropanol was initially synthesized through the hydration of propene at Standard Oil, a major oil refinery. This discovery occurred during the investigation of petroleum by-products. Presently, there are three distinct methods for its production: indirect hydration of propylene, direct hydration of propylene, and catalytic hydrogenation of acetone. The most common method for producing isopropanol is through the indirect hydration of propylene, utilizing a catalytic reaction. Below is a detailed description of the production process:

1. Feedstock Preparation:

- The primary raw material for isopropanol production is propylene (propene), which is obtained from the refining of petroleum or by cracking hydrocarbons. Propylene is a crucial feedstock in this process.

2. Catalytic Dehydration:

- Propylene undergoes catalytic dehydration in the presence of a strong acid catalyst. This step involves the removal of water molecules from propylene, resulting in the formation of isopropyl alcohol (IPA) and diisopropyl ether. The reaction can be represented as follows:

- C3H8O ⇌ C3H6 + H2O

3. Distillation:

- The reaction mixture is then subjected to fractional distillation. This step separates the isopropanol from the diisopropyl ether and unreacted propylene. The goal is to isolate and purify the isopropanol product.

4. Water Removal:

- Isopropanol obtained from the distillation process typically contains some water. To achieve the desired purity level, water is removed from the isopropanol through a drying process. Various methods such as azeotropic distillation or molecular sieves can be employed for water removal.

5. Denaturing (Optional):

- In some cases, isopropanol intended for industrial use or specific applications may undergo a denaturation process. Denaturation involves adding small amounts of substances to the isopropanol to make it unsuitable for consumption. This is particularly important in industries where the use of undenatured ethanol or isopropanol is regulated.

6. Filtration and Filtration Aids:

- The final isopropanol product may undergo filtration to remove any remaining impurities or particulate matter. Filtration aids such as activated carbon or diatomaceous earth may be used to enhance the filtration process.

7. Quality Control:

- Throughout the production process, quality control measures are implemented to ensure that the isopropanol meets the required specifications. These measures may include testing for purity, water content, and other relevant parameters.

8. Packaging:

- The final step involves packaging the purified isopropanol into containers suitable for transportation and distribution. Packaging may vary based on the intended use, ranging from small bottles for retail to larger containers for industrial applications.

Isopropanol Toxicity

Isopropanol can be toxic if ingested, inhaled, or absorbed through the skin in excessive amounts. It is essential to handle and use isopropanol with caution, following safety guidelines and precautions. Here are key points related to isopropanol toxicity:

Ingestion: Ingesting isopropanol can lead to toxicity, causing symptoms such as nausea, vomiting, headache, dizziness, and in severe cases, respiratory depression and central nervous system depression. Ingesting large amounts can be life-threatening.

Inhalation: Inhalation of vapors may lead to respiratory irritation. Prolonged exposure in confined spaces with high concentrations may cause headaches, dizziness, and respiratory distress.

Skin Contact: Isopropanol can be absorbed through the skin, potentially leading to skin irritation. Prolonged or repeated exposure may cause dryness, redness, and irritation.

Eye Contact: Contact with the eyes can cause irritation, redness, and discomfort. Immediate rinsing with water is recommended in case of eye exposure.

Flammability: Isopropanol is highly flammable, and its vapors can form explosive mixtures with air. Proper storage, handling, and use in well-ventilated areas are essential to minimize the risk of fire or explosion.

Precautions: Users should wear appropriate personal protective equipment, including gloves and eye protection, when handling isopropanol. Adequate ventilation is crucial to reduce inhalation exposure.

Children and Pets: Isopropanol should be stored out of reach of children and pets. Ingestion by young children or animals can lead to serious toxicity.

First Aid: In case of exposure or ingestion, seek medical attention immediately. First aid measures may include rinsing affected areas with water, inducing vomiting (if advised by medical professionals), and providing respiratory support if necessary.

Regulatory Compliance: Users should be aware of and adhere to local regulations regarding the handling, storage, and disposal of isopropanol. Understanding safety data sheets (SDS) is essential for comprehensive information on the chemical’s properties and safety measures.

It is imperative for individuals and industries using isopropanol to prioritize safety, implement proper handling procedures, and provide adequate training to personnel. Consulting with safety professionals and following regulatory guidelines ensures the responsible and safe use of isopropanol in various applications.

Isopropanol Storage

Isopropanol, a versatile chemical compound known for its applications in cleaning, disinfection, and industrial processes, requires careful consideration in both storage and disposal to ensure safety and environmental responsibility. This article provides insights into the recommended practices for isopropanol storage and outlines environmentally friendly disposal methods.

Isopropanol Storage:

Isopropanol, commonly referred to as isopropyl alcohol, is a flammable liquid with specific storage requirements to mitigate risks and ensure workplace safety. The following guidelines are essential for proper isopropanol storage:

Container Selection: Isopropanol should be stored in containers made of materials compatible with its properties, such as high-density polyethylene (HDPE) or glass. The containers must be tightly sealed to prevent evaporation and potential hazards.

Ventilation: Storage areas should be well-ventilated to dissipate any fumes that may accumulate. Adequate ventilation helps reduce the risk of flammability and ensures a safe working environment.

Temperature Control: Isopropanol should be stored in cool, well-ventilated areas away from heat sources and direct sunlight. Maintaining a stable temperature helps prevent the buildup of internal pressure in containers and minimizes the risk of ignition.

Separation from Incompatible Substances: Isopropanol should be stored separately from incompatible substances, including strong oxidizers, acids, and bases. Proper segregation helps prevent chemical reactions that may compromise safety.

Fire Prevention Measures: Fire prevention measures, such as the installation of fire extinguishers and fire suppression systems, should be in place. Adequate training on fire safety procedures is crucial for personnel working with or around isopropanol storage areas.

Advantages of the Chinese Isopropanol Market

1. Robust Manufacturing Infrastructure:

China boasts a robust manufacturing infrastructure that has played a pivotal role in the growth of its isopropanol market. The country’s well-established chemical manufacturing facilities and technological capabilities contribute to the efficient production and supply of isopropanol.

2. Large-Scale Production Capacity:

The Chinese isopropanol market benefits from substantial production capacities. China’s ability to meet the high demand for isopropanol, both domestically and internationally, positions it as a major supplier in the global market. The scale of production allows for economies of scale, contributing to cost-effectiveness.

3. Competitive Pricing:

The large-scale production capacity in China enables competitive pricing in the isopropanol market. The cost efficiencies achieved through economies of scale translate into competitive prices for isopropanol products. This advantage makes Chinese isopropanol attractive to both domestic and international buyers.

4. Strategic Geographic Location:

China’s strategic geographic location provides a logistical advantage in terms of distribution and export. Proximity to key markets in Asia and beyond facilitates efficient transportation, reducing lead times and costs associated with the movement of isopropanol products.

5. Research and Development Capabilities:

The Chinese chemical industry has invested significantly in research and development, contributing to technological advancements and product innovation. This focus on R&D enhances the quality and diversity of isopropanol products, meeting the evolving needs of various industries.

6. Growing End-User Industries:

The thriving end-user industries in China, such as electronics, pharmaceuticals, and healthcare, contribute to the sustained demand for isopropanol. The growth of these industries creates a stable market for isopropanol products, driving the expansion of the market.

7. Regulatory Support and Compliance:

China’s regulatory environment supports the growth of the isopropanol market by ensuring compliance with international standards. Adherence to regulatory requirements enhances product quality and safety, instilling confidence in both domestic and international buyers.

8. Global Export Hub:

The Chinese isopropanol market serves as a global export hub, meeting the demands of various international markets. The country’s export-oriented approach has established it as a key supplier, with Chinese isopropanol reaching regions across Asia, Europe, and the Americas.

9. Increasing Focus on Sustainability:

China’s chemical industry has shown a growing commitment to sustainability and environmental responsibility. This focus aligns with global trends, making Chinese isopropanol products attractive to environmentally conscious industries seeking sustainable chemical solutions.

10. Continuous Market Expansion:

The Chinese isopropanol market continues to expand, driven by both domestic consumption and international demand. This expansion creates new opportunities for market players, fostering innovation, and reinforcing China’s position as a leading force in the global isopropanol market.

Our Team

FAQs of Isopropanol

A1: As a supplier, our isopropanol is of the highest quality, boasting a purity level exceeding 99%. Our commitment to excellence ensures that our isopropanol meets and exceeds industry standards, guaranteeing optimal performance for various applications.

A2: You should have the appropriate qualifications if you need to buy hazardous chemicals such as isopropanol. As a responsible supplier, we ensure compliance with relevant standards and may request documentation to confirm the buyer’s eligibility, prioritizing safety and regulatory adherence.

A3: Isopropanol (or isopropyl alcohol) is most commonly sold as rubbing alcohol, in a 70% solution. It can also be found in antifreezes, glass cleaners, jewelry cleaner, stain removers, deicers, household disinfectants, and hand sanitizers.

A4: Isopropyl alcohol kills or prevents the growth of bacteria on the skin. Isopropyl alcohol topical (for use on skin) is used to help prevent bacterial skin infections from minor cuts or scrapes. Isopropyl alcohol is used in healthcare settings to prevent infection that may be caused by needle punctures.

A5: Inhaling Isopropyl Alcohol can irritate the nose and throat. Repeated high exposure can cause headache, dizziness, confusion, loss of coordination, unconsciousness and even death.

A6: Absolutely. We offer 100g-200g samples, with the client only covering shipping costs.

A7: Standard lead times are approximately 2-4 weeks, varying based on order size and destination.

A8: Our standard payment terms include a 30% advance and the balance against delivery, but terms can be negotiated for long-term partnerships.

A9: Yes, we offer comprehensive after-sales support, addressing any post-purchase queries or concerns.

A10: As a supplier, in order to provide you with an accurate quote for your product, please inform us of the quantity you require, the required purity specifications, any specific packaging needs, your shipping location, and whether your application requires any customization requirements or certifications.