n-Propyl acetate

In today’s competitive market, finding a solvent that not only meets your rigorous quality standards but also aligns with environmental and safety regulations is paramount. N-Propyl Acetate stands out as a versatile, high-performance solution for industries ranging from pharmaceuticals to food flavoring and manufacturing. With its exceptional purity and quality, N-Propyl Acetate is the choice for businesses aiming for excellence.

Why Choose Our N-Propyl Acetate?

High Purity & Quality

Our N-Propyl Acetate is engineered to meet the highest standards, ensuring that your products perform consistently at their peak. The exceptional purity of our solvent means you can rely on it for critical applications where quality cannot be compromised.

Regulatory Compliance

Navigating the complex landscape of global safety and environmental regulations is challenging. Our N-Propyl Acetate complies with all major regulatory bodies, including REACH and OSHA, providing you with peace of mind and simplifying your compliance efforts.

Supply Reliability

We understand the importance of a reliable supply chain. Our robust logistics network ensures short lead times and consistent delivery, so you never have to worry about delays or disruptions in your production schedule.

Table of Contents

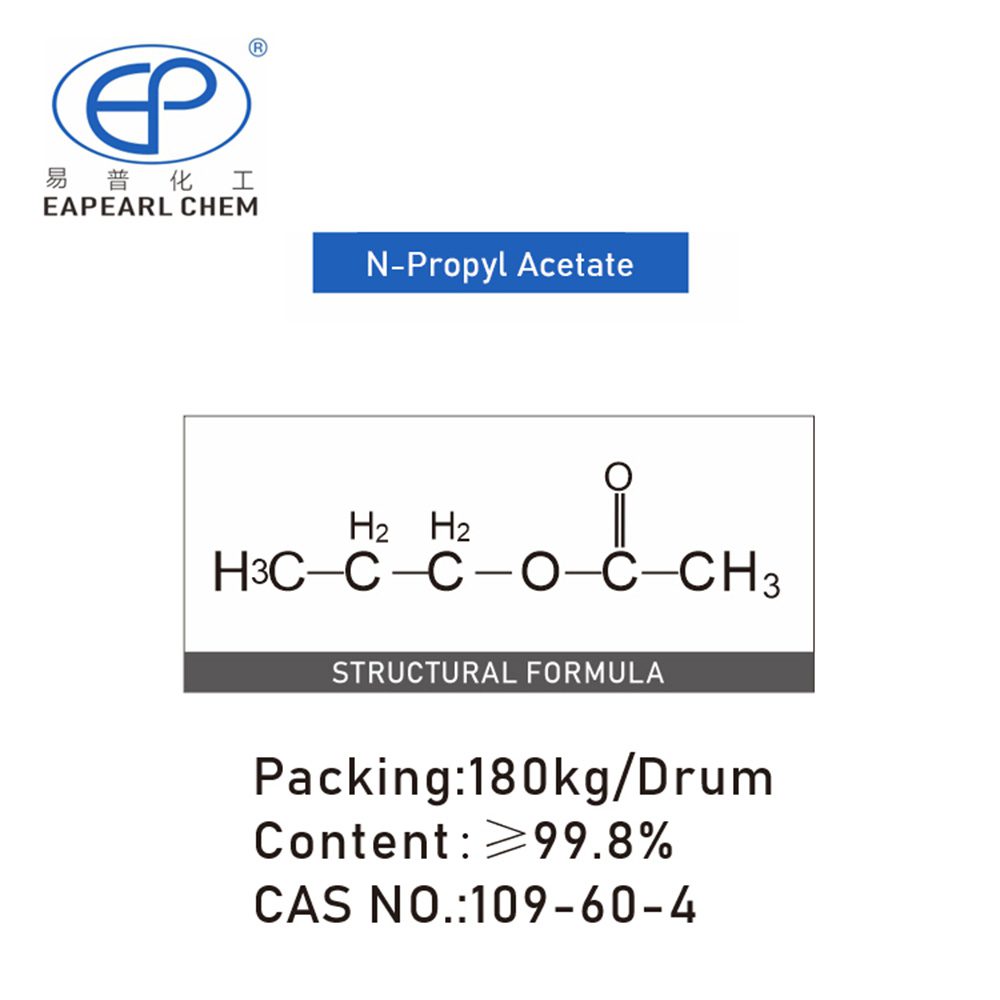

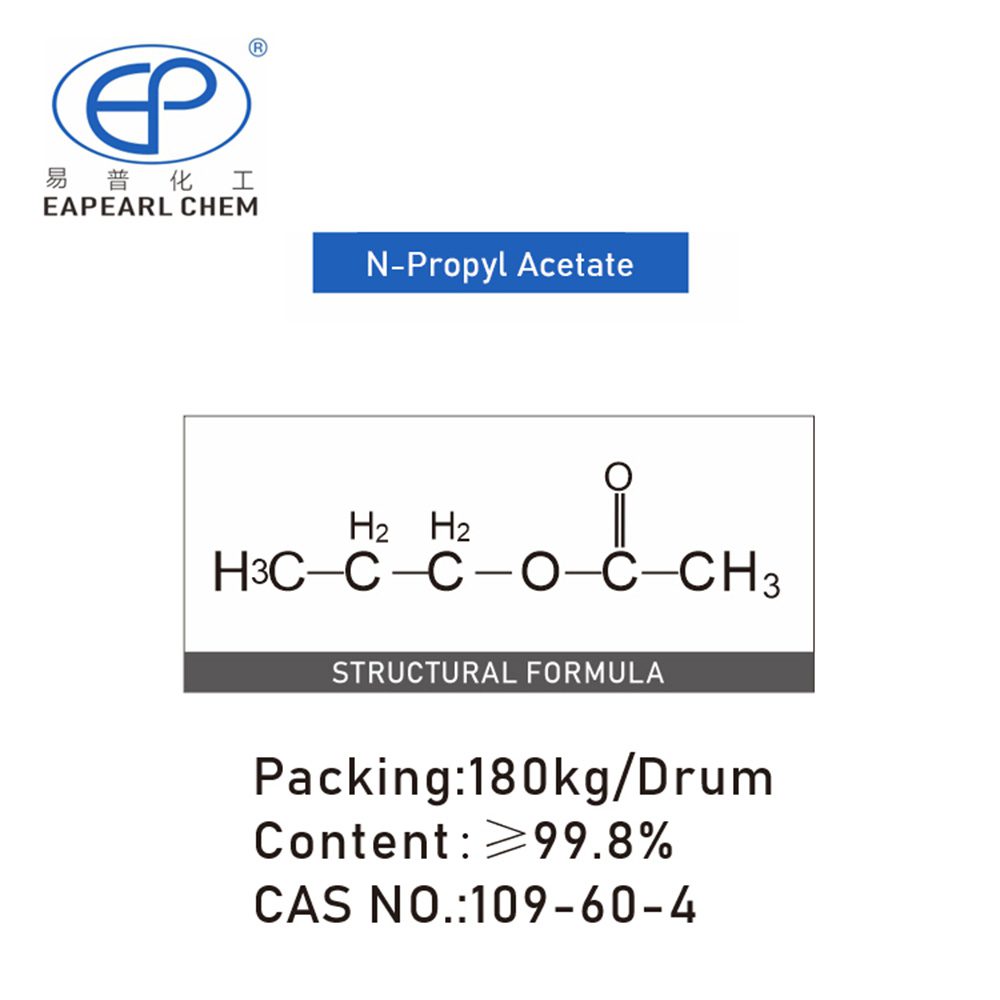

N-Propyl Acetate, also known by its chemical name Propyl Ethanoate, is an organic compound with the formula C₃H₇COOCH₃. This ester is formed from the esterification of acetic acid and propanol. Known for its fruity odor, N-Propyl Acetate is a colorless liquid that is used in various applications across the food, fragrance, and manufacturing industries.

Synonyms: NPAC, octanpropylu, PROPYL ACETATE, 1-propylacetate, N-PROPYL ACETATE, N-BUTYLE BROMURE, 1-Propyl acetate, 1-Acetoxypropane, Acetic acid n-propyl ester

Nature: As a chemical entity, N-Propyl Acetate is characterized by its moderate boiling point and its distinctive, pleasant fruity smell, reminiscent of pears. It is a volatile, flammable liquid with a boiling point of 101.6 °C (214.9 °F) and a density of 0.888 g/cm³ at 20 °C (68 °F). Soluble in most organic solvents, N-Propyl Acetate has limited solubility in water, making it an ideal solvent for various organic compounds.

N-Propyl Acetate Packaging Information

| NPAC packaging | Capacity | 20GP | 40GP |

| drum | 180 kg /drum | total 80 drums, Net 14.4 ton | total 136 drums, Net 24.48 ton |

| IBC drum | 860 kg /IBC | total 20 IBC, Net 17.2 ton | total 30 IBC, Net 25.8 ton |

| ISO Tank | 20.5 ton /ISO Tank | 1 ISO Tank, Net 20.5 ton | N/A |

For N-Propyl acetate, we welcome you to test and check the quality, if you need a sample please contact our sales team to discuss your sample requirements, we believe that our product quality is suitable for the specific application. We provide samples free of charge but the shipping cost will be borne by you.

Applications of N-Propyl Acetate

N-Propyl acetate is a versatile organic compound with a wide range of applications across various industries due to its excellent solvent properties and pleasant fruity odor. Below are detailed descriptions of its specific applications:

Solvent in Paints and Coatings

N-Propyl acetate is a preferred solvent in the formulation of various paints and coatings due to its excellent solubility for many synthetic resins. Its balanced evaporation rate ensures that paints and coatings dry quickly but not so fast that it affects the application quality, allowing for smooth finishes without brush marks or blushing. This characteristic is particularly beneficial in automotive paints and high-gloss finishes where a flawless appearance is crucial. Moreover, its use contributes to reducing the overall volatile organic compound (VOC) content in paints, aiding manufacturers in meeting environmental regulations without compromising on performance.

Printing Inks Industry

In the realm of printing inks, N-propyl acetate’s solvency properties are critical for dissolving dyes and pigments, ensuring they remain in solution form throughout the printing process. This capability is essential for producing inks that are consistent in color and viscosity, which is vital for high-quality printing on various media. Its rapid drying helps in the fast setting of inks, a necessary feature for packaging materials that are printed in large volumes and require immediate handling or further processing. The use of N-propyl acetate in inks also enhances the adhesion of the ink to substrates, making it ideal for printing on non-porous materials.

Pharmaceutical Applications

N-Propyl acetate’s role in pharmaceutical manufacturing extends to its use as a solvent in the extraction and purification processes of active pharmaceutical ingredients (APIs). Its chemical stability and low toxicity make it a safe choice for processes that require stringent purity standards. Additionally, in topical formulations, N-propyl acetate helps in dissolving active ingredients and ensures they are evenly distributed throughout the product, enhancing the efficacy of topical drugs and cosmetic products.

Food Flavoring Agent

The application of N-propyl acetate as a flavoring agent is based on its ability to impart a sweet, fruity flavor reminiscent of pears and apples, making it a popular choice for enhancing or adding fruit flavors to food and beverages. Its volatility is advantageous in flavor applications because it ensures the flavor is released promptly upon consumption, enhancing the taste experience. The use of N-propyl acetate in food products is carefully regulated, with strict adherence to safety and quality standards to ensure consumer safety.

Fragrance Ingredient in Cosmetics and Personal Care Products

In cosmetics and personal care products, N-propyl acetate is valued not only for its pleasant scent but also for its role in enhancing the overall fragrance profile of products. It acts as a fixative that helps in stabilizing the volatility of other fragrance components, prolonging the scent’s longevity on the skin. This property is particularly beneficial in perfumes and colognes, where a lasting fragrance is desired. Its compatibility with other cosmetic ingredients and its non-irritating nature make it suitable for use in a wide range of personal care products.

Adhesives and Sealants

The effectiveness of N-propyl acetate in adhesives and sealants lies in its ability to dissolve and interact with polymers, facilitating the formation of bonds at the molecular level. This interaction ensures that adhesives have the necessary strength and flexibility for their intended applications, from household use to industrial bonding and sealing tasks. Its fast evaporation rate aids in the quick setting of adhesives, an essential feature for applications requiring rapid assembly or production processes.

Cleaning Agents and Degreasers

The utility of N-propyl acetate in cleaning agents and degreasers is attributed to its strong solvency for organic materials, such as oils, greases, and waxes. This makes it an effective component in formulations designed for cleaning engines, machinery, and electronic components, where the removal of stubborn residues is required without damaging the underlying material. Its effectiveness as a degreaser is particularly valued in industrial maintenance and repair operations, where clean surfaces are essential for the proper functioning of equipment.

Each of these applications demonstrates the versatility and importance of n-propyl acetate in industrial and consumer products. Its selection for a particular use depends on factors such as solvency requirements, drying time considerations, regulatory compliance, and the desired sensory attributes of the final product. If you have any questions about the application of N-Propyl Acetate, please contact our team of experts.

REQUEST A QUOTE FOR MORE DETAILS

Technical Data of N-Propyl Acetate

| Name | N-Propyl Acetate |

| Synonyms | NPAC, octanpropylu, PROPYL ACETATE, 1-propylacetate, N-PROPYL ACETATE, N-BUTYLE BROMURE, 1-Propyl acetate, 1-Acetoxypropane, Acetic acid n-propyl ester |

| CAS | 109-60-4 |

| EINECS | 203-686-1 |

| Molecular Formula | C5H10O2 |

| Molar Mass | 102.13 |

| Density | 0.888 g/mL at 25 °C (lit.) |

| Melting Point | -95 °C (lit.) |

| Boling Point | 102 °C (lit.) |

| Flash Point | 55°F |

| JECFA Number | 126 |

| Water Solubility | 2g/100 mL (20 ºC) |

| Solubility | water: soluble |

| Vapor Presure | 25 mm Hg ( 20 °C) |

| Vapor Density | 3.5 (vs air) |

| Appearance | Liquid |

| Specific Gravity | 0.889 (20/4℃) |

| Color | APHA: ≤15 |

| Odor | Mild fruity. |

| Exposure Limit | TLV-TWA 200 ppm (~840 mg/m3) (ACGIH,MSHA, and OSHA); TLV-STEL 250 ppm(~1050 mg/m3) (ACGIH); IDLH 8000 ppm(NIOSH). |

| Merck | 147,841 |

| BRN | 1740764 |

| Storage Condition | Store below +30°C. |

| Stability | Stable. Highly flammable. May react violently with oxidizing agents. May form explosive mixtures with air. Incompatible with strong oxidizing agents, acids, bases. |

| Explosive Limit | 1.7%, 37°F |

| Refractive Index | n20/D 1.384(lit.) |

| Physical and Chemical Properties | Colorless liquid with mild fruit aroma. |

| melting point -92.5 ℃ | |

| boiling point 101.6 ℃ | |

| relative density 0.8878 | |

| refractive index 1.3844 | |

| flash point 14 ℃ | |

| solubility, ketones and hydrocarbons are miscible and slightly soluble in water. | |

| HS Code | 2915 39 00 |

| LogP | 1.4 at 25℃ |

N-Propyl Acetate Production

The production of N-Propyl Acetate, an ester formed from the reaction of N-propanol (propyl alcohol) with acetic acid, involves a process known as esterification. This chemical reaction is typically catalyzed by an acid. Below is a detailed outline of the specific production process for N-Propyl Acetate, highlighting the steps involved from the preparation of raw materials to the final product purification.

1. Preparation of Raw Materials

N-Propanol and Acetic Acid: The primary raw materials required for the production of N-Propyl Acetate are N-propanol and acetic acid. These materials must be of high purity to ensure the quality of the final product. They are stored in separate tanks and are typically pre-heated to a temperature close to the reaction temperature to improve the reaction efficiency.

Acid Catalyst: A strong acid catalyst, such as sulfuric acid, is used to accelerate the esterification reaction. The catalyst is prepared and stored in a way that allows for controlled addition to the reaction mixture.

2. Esterification Reaction

Mixing of Reactants: N-Propanol and acetic acid are pumped into a reaction vessel in a stoichiometric ratio, often with a slight excess of acetic acid to drive the reaction towards the formation of the ester. The exact ratio can vary based on the specific process design and desired yield.

Catalyst Addition: The acid catalyst is added to the mixture in the reaction vessel. The amount of catalyst can vary, but it is typically a small percentage of the total volume of the reactants.

Heating and Reaction: The reaction mixture is heated to initiate the esterification process. The typical reaction temperature ranges from 60°C to 120°C, depending on the specific catalyst and process conditions. The reaction vessel is equipped with a reflux condenser to condense and return any vapors back to the mixture, maintaining a constant volume and concentration of reactants.

Reaction Equation: The esterification reaction can be represented by the following chemical equation: CH3CH2CH2OH+CH3COOH→CH3COOCH2CH2CH3+H2O (n-Propanol + Acetic Acid → N-Propyl Acetate + Water)

3. Removal of Water

- Water Separation: To drive the reaction towards complete conversion to N-Propyl Acetate, the water produced as a by-product must be continuously removed from the reaction mixture. This can be achieved through azeotropic distillation or by using a drying agent.

4. Product Purification

Distillation: After the reaction is complete, the mixture is subjected to distillation to separate the N-Propyl Acetate from unreacted raw materials, the catalyst, and other by-products. The distillation process may involve multiple stages, including the use of a fractionating column to achieve high purity N-Propyl Acetate.

Neutralization of Catalyst: If an acid catalyst was used, the acidic residues in the product stream need to be neutralized, typically using a base such as sodium bicarbonate.

5. Quality Control and Packaging

Quality Testing: The purified N-Propyl Acetate is tested to ensure it meets the required specifications for purity, acidity, and other relevant parameters.

Packaging: Once approved, the N-Propyl Acetate is packaged in suitable containers, such as drums or bulk tanks, for storage and distribution.

REQUEST A QUOTE FOR MORE DETAILS

How can we handle your order?

step 1

We will communicate with you within 24 hours after you send an enquiry.

step 2

If you need sample testing, we will send samples within 5 days,≤50kg, Express delivery recommended, usually called as DDU service; delivery time 5-7 days. Door to door service.

step 3

If you need bulk goods after the sample test is qualified, we will ship the goods to the port and keep the samples within 6 days after the order is confirmed. Sea shipping recommended, usually called as FOB, CFR, or CIF service.delivery time 10-45 days. Port to port service.

step 4

After waiting for you to receive the goods, we will arrange professional staff to pay a return visit within 7 days.

N-Propyl Acetate: Storage and Environmental Disposal

Storage of N-Propyl Acetate

Conditions

N-Propyl acetate should be stored in a cool, well-ventilated area away from direct sunlight and sources of ignition, as it is a flammable liquid. The storage area should be equipped with explosion-proof electrical equipment and materials to contain spills. The compound should be kept in tightly closed containers made of materials compatible with N-Propyl acetate, such as stainless steel, certain plastics, or glass, to prevent leakage and contamination.

Safety Measures

- Fire Prevention: Because of its flammability, N-Propyl acetate requires storage in areas free from open flames, sparks, and static discharge. Fire-fighting measures, including appropriate extinguishers and sprinkler systems, should be readily accessible.

- Leak and Spill Management: Facilities should have spill containment measures in place, such as spill kits with absorbent materials and containment booms, to quickly address any accidental releases.

- Personal Protective Equipment (PPE): Individuals handling N-Propyl acetate should wear suitable protective gear, including chemical-resistant gloves, eye protection, and respirators if necessary.

Environmental Disposal of N-Propyl Acetate

Regulations

The disposal of N-Propyl acetate must comply with local, state, and federal environmental regulations. These regulations often require that hazardous chemicals be treated or neutralized before disposal to minimize their impact on the environment.

Methods

- Incineration: N-Propyl acetate can be disposed of through high-temperature incineration in facilities equipped with scrubbers or afterburners to treat emissions. This method effectively reduces the volume of waste and neutralizes potential environmental hazards.

- Chemical Treatment: Chemical neutralization involves reacting N-Propyl acetate with a suitable agent to form less harmful substances that are safer for disposal.

- Waste Management Services: Companies may also opt to use certified hazardous waste management services that specialize in the disposal of chemicals like N-Propyl acetate. These services ensure that the compound is disposed of in a manner that complies with all regulatory requirements.

Advantages of the Chinese N-Propyl Acetate Market

The Chinese N-Propyl acetate market has seen significant growth over the past few years, driven by the country’s expanding industrial sector and strategic market positioning. N-Propyl acetate, a solvent known for its excellent solvency and pleasant fruity odor, is widely used in various applications, including paints, coatings, inks, and the food and fragrance industries. This part explores the advantages of the Chinese N-Propyl acetate market, highlighting why it has become a global leader in the production and supply of this essential chemical.

Diverse Industrial Base

China’s vast and diverse industrial base provides a robust internal demand for N-Propyl acetate. The country’s well-established chemical, pharmaceutical, food, and cosmetics industries offer a stable market for N-Propyl acetate, ensuring consistent demand that supports market growth and stability.

Advanced Manufacturing Capabilities

China’s investment in advanced manufacturing technologies has enhanced its capacity to produce high-quality N-Propyl acetate efficiently and at competitive costs. State-of-the-art facilities ensure that production meets global standards, catering to both domestic and international markets.

Economies of Scale

The large scale of production facilities in China, combined with an integrated supply chain, contributes to economies of scale that are difficult to match. This allows Chinese manufacturers to offer N-Propyl acetate at more competitive prices than their counterparts in other countries.

Access to Raw Materials

China’s access to a broad range of raw materials, including acetic acid and N-Propanol (the primary components needed to produce N-Propyl acetate), reduces the cost and complexity of the supply chain. This access, coupled with efficient logistics networks, further enhances the market’s cost competitiveness.

Government Policies

The Chinese government’s supportive policies towards the chemical industry, including subsidies and incentives for sustainable and environmentally friendly practices, have bolstered the growth of the N-Propyl acetate market. These policies encourage innovation and investment in cleaner production technologies, aligning with global environmental trends.

Environmental Management

Chinese manufacturers are increasingly adopting green chemistry principles and waste management practices to minimize the environmental impact of N-Propyl acetate production. This shift not only reduces ecological footprints but also appeals to environmentally conscious consumers and industries worldwide.

Expanding Global Footprint

China’s strategic geographical location and established export infrastructure facilitate easy access to key global markets. The country’s N-Propyl acetate manufacturers have capitalized on this, expanding their footprint in Asia, Europe, and the Americas.

Quality and Standards

Chinese N-Propyl acetate producers have made significant strides in quality assurance, adhering to international standards to meet the stringent requirements of global markets. This commitment to quality has enhanced China’s reputation as a reliable source of N-Propyl acetate.

Our Team

FAQs of N-Propyl Acetate

A1: N-Propyl Acetate is widely used as a solvent in the production of paints, coatings, and inks, as well as a flavoring agent in the food industry due to its pleasant, fruity odor. It also finds applications in the pharmaceutical and cosmetics industries.

A2: To purchase N-Propyl Acetate, buyers must confirm their qualification for handling and purchasing dangerous chemicals. This typically involves businesses or individuals who:

- Are registered with relevant environmental and safety regulatory bodies.

- Have a valid business license for industries that require the use of such chemicals (e.g., manufacturing, pharmaceuticals, food processing).

- Can demonstrate adequate knowledge and facilities for safe storage and handling according to local regulations.

A3: Handling N-Propyl Acetate safely requires:

- Compliance with local safety and environmental regulations.

- Proper training in chemical handling and safety procedures.

- Adequate storage facilities that meet fire safety and environmental protection standards.

- Personal protective equipment (PPE) for individuals who will be in direct contact with the chemical.

A4: Safety considerations include:

- Storing in a cool, well-ventilated area away from heat sources and ignition points.

- Using containers made of materials compatible with N-Propyl Acetate, such as stainless steel or certain types of plastic.

- Implementing spill containment measures and having spill kits readily available.

- Regularly checking storage containers for leaks or damage.

A5: Yes, N-Propyl Acetate can be used as a flavoring agent in food products, but it must be of food-grade quality and used within regulatory limits set by food safety authorities. Always verify the product’s suitability for food use and compliance with local regulations before purchase.

A6: N-Propyl Acetate is crucial due to its excellent solvent properties, facilitating diverse applications from industrial to consumer products. It’s widely used in the manufacture of paints, coatings, and inks, enhancing drying times and finish quality. Additionally, its pleasant, fruity aroma makes it a preferred choice as a flavoring agent in foods and a fragrance component in cosmetics, showcasing its versatility and value across sectors.

A7: Absolutely. We offer 100g-200g samples, with the client only covering shipping costs.

A8: Standard lead times are approximately 2-4 weeks, varying based on order size and destination.

A9: Our standard payment terms include a 30% advance and the balance against delivery, but terms can be negotiated for long-term partnerships.

A10: Yes, we offer comprehensive after-sales support, addressing any post-purchase queries or concerns.

A11: As a supplier, in order to provide you with an accurate quote for your product, please inform us of the quantity you require, the required purity specifications, any specific packaging needs, your shipping location, and whether your application requires any customization requirements or certifications.