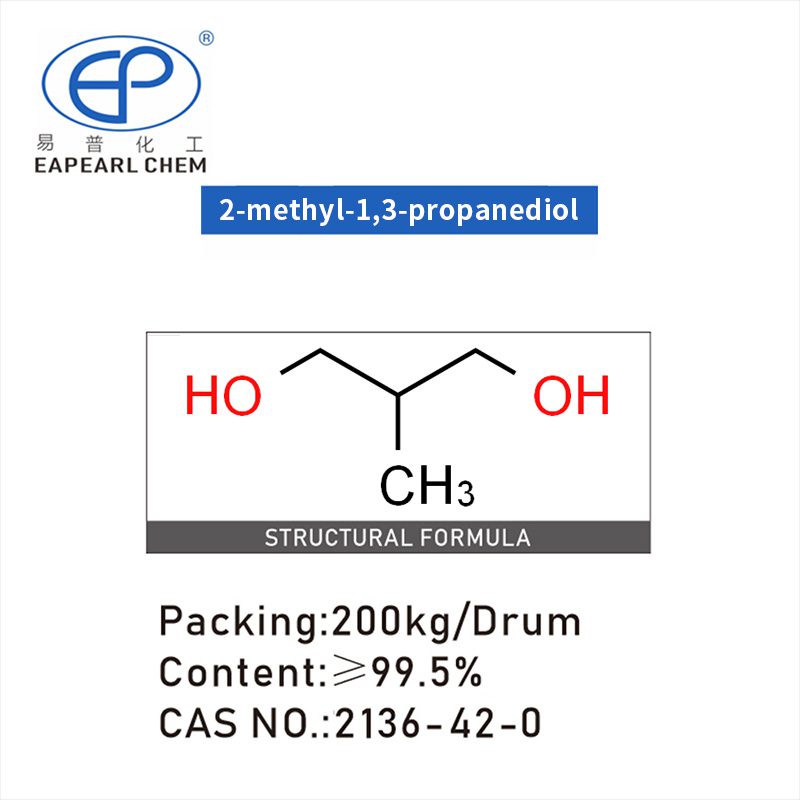

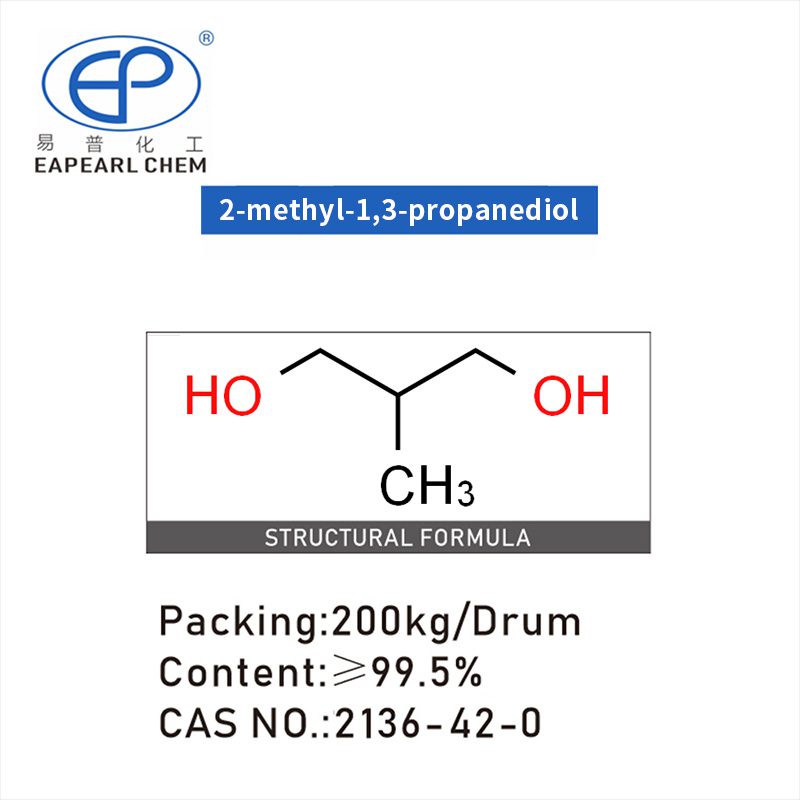

2-methyl-1,3-propanediol(MPO)

Introduction: 2-Methyl-1,3-propanediol is a colorless, viscous liquid at room temperature, known for its excellent solvent properties and stability. Its molecular formula is C4H10O2, reflecting a propanediol backbone with a methyl group substitution that enhances its chemical behavior and utility across different sectors.

Synonyms: Methyl propane diol (MP Diol);2-Methyl-1,3-propanediol 99%;1,3-DIHYDROXY-2-METHYLPROPANE;2-METHYL-PROPAN-1,3-DIOL;2-METHYL-1,3-PROPANEDIOL;2-methyl-3-propanediol;3-Propanediol,2-methyl-1.

Nature: As a diol, MPO possesses two hydroxyl groups attached to different carbon atoms in its molecular structure, contributing to its high boiling point and solubility in water and organic solvents. The presence of the methyl group not only influences its physical and chemical properties but also improves its performance in specific applications compared to its analogs.

Unlock the full potential of your products with our high-grade 2-Methyl-1,3-Propanediol (MPO), the cornerstone for innovation in the pharmaceutical, cosmetic, and polymer industries. Experience unparalleled purity, versatility, and sustainability with our premium MPO.

Discover the MPO Difference

In a world where quality and performance cannot be compromised, our MPO stands out as the superior choice. As a leading 2-Methyl-1,3-Propanediol supplier, we commit to providing a product that not only meets but exceeds industry standards.

Why Choose Our MPO?

- Unmatched Purity: Rigorous quality control ensures our MPO delivers consistent, high-quality results for your products.

- Versatile Applications: From enhancing pharmaceutical formulations to creating durable polymers and eco-friendly cosmetics, MPO is your solution.

- Sustainability Commitment: We prioritize environmental responsibility, offering an MPO that supports your green manufacturing goals.

Table of Contents

2-Methyl-1,3-Propanediol Packaging Information

| MPO Packaging | Capacity | 20GP | 40GP |

| drum | 200 kg /drum | total 80 drums, Net 16 ton | total 128 drums, Net 25.6 ton |

| IBC | 1 ton /IBC | total 20 IBC, Net 20 ton | total 26 IBC, Net 26 ton |

| flexibag | 24 ton /flexibag | 1 flexibag, Net 24 ton | N/A |

| ISO Tank | 24 ton /ISO Tank | 1 ISO Tank, Net 24 ton | N/A |

For 2-methyl-1,3-propanediol, we welcome you to test and check the quality, if you need a sample please contact our sales team to discuss your sample requirements, we believe that our product quality is suitable for the specific application, we provide samples free of charge but the shipping cost will be borne by you.

Applications of 2-Methyl-1,3-Propanediol

2-Methyl-1,3-propanediol (MPO) finds its utility in a variety of applications across different industries, leveraging its unique chemical structure and properties. Below are detailed descriptions of its specific applications:

Polymer Production

Polyurethanes

- Description: MPO is used as a monomer in the synthesis of polyurethanes, contributing to the polymer’s flexibility, durability, and resistance to water and chemicals. Polyurethanes made with MPO are employed in a wide range of products, including flexible foams for furniture and automotive seats, rigid foams for insulation, elastomers for wheels and tires, and adhesives and sealants for various applications.

- Benefits: The inclusion of MPO enhances the polymer’s mechanical properties, such as tensile strength and abrasion resistance. It also improves polyurethane’s adhesion to various substrates and reduces its viscosity, making the polymer easier to process.

Polyester Resins

- Description: In polyester production, MPO serves as a component of the polyol blend. Polyesters formulated with MPO are used in high-performance coatings, fiberglass-reinforced plastics, and thermoplastic polyesters.

- Benefits: MPO imparts superior hydrolytic stability, making these materials more durable in wet or humid environments. Additionally, it contributes to the thermal stability and mechanical strength of the final product, enhancing its utility in both industrial and consumer goods.

Cosmetic Industry

Skincare and Beauty Products

- Description: MPO is utilized as a solvent and humectant in cosmetics, including lotions, creams, and serums. Its role is to enhance the texture and stability of these products, while also aiding in moisture retention.

- Benefits: The compound’s low toxicity and compatibility with various ingredients make it safe for topical application. It helps in formulating non-irritating skincare products that provide hydration and improve skin feel.

Pharmaceutical Formulations

Solvent and Carrier

- Description: In pharmaceuticals, MPO is used as a carrier or solvent for active pharmaceutical ingredients (APIs). It facilitates the effective delivery of medications by improving solubility and stability.

- Benefits: The non-toxic nature of MPO ensures that it does not interfere with the drug’s efficacy or cause adverse reactions. It enables the development of stable, effective medication formulations, particularly for topical and injectable drugs.

Industrial Solvents

Cleaning Agents and Coatings

- Description: MPO’s solvent properties make it suitable for use in industrial cleaning agents and coatings. It can dissolve a wide range of substances, making it ideal for formulations requiring a versatile solvent.

- Benefits: Besides its efficacy as a solvent, MPO’s low volatility and high boiling point reduce the risk of evaporation and loss during application. This makes it an environmentally friendlier option for industrial use, contributing to safer work environments and reduced volatile organic compound (VOC) emissions.

Functional Fluids

Heat Transfer Fluids

- Description: MPO is used in the formulation of heat transfer fluids, which are essential in systems requiring the efficient transfer of heat. Its chemical stability at high temperatures and compatibility with various materials make it an excellent choice for such applications.

- Benefits: The use of MPO in heat transfer fluids enhances their thermal stability, ensuring consistent performance over a wide temperature range. This property is crucial for maintaining the efficiency and longevity of heat transfer systems in industrial processes.

These applications of 2-Methyl-1,3-propanediol (MPO) highlight its versatility and importance across various sectors. Its unique properties, such as low toxicity, high boiling point, and excellent solvent capabilities, make it an invaluable component in the development of advanced materials and products. If you have any questions about the application of 2-methyl-1,3-propanediol (MPO), please contact our expert team.

REQUEST A QUOTE FOR MORE DETAILS

Technical Data of 2-Methyl-1,3-Propanediol

| Name | 2-Methyl-1,3-Propanediol |

| Synonyms | MPO; Methyl propane diol (MP Diol);2-Methyl-1,3-propanediol 99%;1,3-DIHYDROXY-2-METHYLPROPANE;2-METHYL-PROPAN-1,3-DIOL;2-METHYL-1,3-PROPANEDIOL;2-methyl-3-propanediol;3-Propanediol,2-methyl-1 |

| CAS | 2163-42-0 |

| EINECS | 412-350-5 |

| Molecular Formula | C4H10O2 |

| Molar Mass | 90.12 |

| Density | 1.015 g/mL at 25 °C (lit.) |

| Melting Point | -91 °C (lit.) |

| Boling Point | 123-125 °C/20 mmHg (lit.) |

| Flash Point | >230°F |

| Solubility | Chloroform (Soluble), DMSO (Slightly), Methanol (Slightly) |

| Vapor Presure | 0.0225mmHg at 25°C |

| Vapor Density | 3.2 (vs air) |

| Appearance | Oil |

| Color | Colourless |

| Odor | little to no odor |

| BRN | 1731422 |

| pKa | 14.51±0.10(Predicted) |

| Storage Condition | Sealed in dry,Room Temperature |

| Refractive Index | n20/D 1.445(lit.) |

| LogP | -0.740 (est) |

2-Methyl-1,3-Propanediol Production

The production of 2-Methyl-1,3-propanediol (MPO) can be achieved through several synthetic routes, with the most common method involving the hydrogenation of methyl acrylate to form MPO. This process is complex and requires careful control of reaction conditions to ensure high yield and purity of the final product. Below is a simplified outline of a typical production process for MPO:

1. Raw Material Preparation

- Starting Materials: The primary raw materials used in the production of MPO are methyl acrylate and hydrogen gas. Methyl acrylate serves as the carbon source that will be transformed into MPO through a series of chemical reactions.

- Purification: Prior to reaction, these materials may need to be purified to remove impurities that could interfere with the production process or degrade the quality of the final product.

2. Hydrogenation Reaction

- Catalyst Preparation: A catalyst, typically a transition metal catalyst such as palladium on carbon (Pd/C), is prepared and activated to facilitate the hydrogenation reaction.

- Reaction Setup: The reaction is conducted in a high-pressure reactor. Methyl acrylate and hydrogen gas are introduced into the reactor, along with the catalyst.

- Reaction Conditions: The hydrogenation of methyl acrylate is carried out under controlled temperature and pressure conditions. The temperature is typically maintained around 100-150°C, and the pressure is adjusted to ensure an excess of hydrogen is present to drive the reaction forward.

- Monitoring: Throughout the reaction, continuous monitoring is essential to ensure that the reaction proceeds as expected. Parameters such as temperature, pressure, and hydrogen uptake are closely watched.

3. Product Isolation and Purification

- Cooling and Decompression: After the completion of the reaction, the mixture is cooled and decompressed to ambient pressure.

- Separation of Catalyst: The catalyst is removed from the reaction mixture. This is often achieved through filtration or centrifugation.

- Distillation: The crude MPO is purified through distillation to remove unreacted starting materials, by-products, and other impurities. This step may involve multiple distillation stages under vacuum to achieve high purity.

- Quality Control: Samples of the purified MPO are tested for purity, chemical composition, and other properties to ensure they meet the required specifications for industrial use.

4. Packaging and Storage

- Packaging: The purified MPO is transferred to appropriate containers, such as drums or tanks, designed for safe storage and transportation.

- Storage Conditions: MPO should be stored in a cool, dry place away from light and heat sources to prevent degradation or unwanted reactions.

5. Waste Treatment and Environmental Compliance

- Waste Handling: By-products and waste materials generated during the production process are treated according to environmental regulations. This may involve neutralization, recycling, or disposal in designated facilities.

- Emissions Control: Efforts are made to minimize emissions of volatile organic compounds (VOCs) and other pollutants. This can include the use of scrubbers, filters, and adherence to strict environmental standards.

REQUEST A QUOTE FOR MORE DETAILS

How can we handle your order?

step 1

We will communicate with you within 24 hours after you send an enquiry.

step 2

If you need sample testing, we will send samples within 5 days,≤50kg, Express delivery recommended, usually called as DDU service; delivery time 5-7 days. Door to door service.

step 3

If you need bulk goods after the sample test is qualified, we will ship the goods to the port and keep the samples within 6 days after the order is confirmed. Sea shipping recommended, usually called as FOB, CFR, or CIF service.delivery time 10-45 days. Port to port service.

step 4

After waiting for you to receive the goods, we will arrange professional staff to pay a return visit within 7 days.

2-Methyl-1,3-Propanediol (MPO) Compared to Other Diols

2-Methyl-1,3-Propanediol (MPO), Propylene Glycol (PG), and 1,3-Propanediol (PDO) are diols with similar chemical structures but distinct properties. All are colorless, odorless liquids miscible with water and many solvents. They serve as solvents, humectants, and viscosity modifiers, finding applications in cosmetics, pharmaceuticals, and more. However, they differ in their chemical compositions and uses. MPO contains a methyl group, making it suitable for cosmetics and pharmaceuticals. PG, with hydroxyl groups on the first and second carbon atoms, is prevalent in food, pharmaceuticals, and e-liquids. PDO, with hydroxyl groups on the first and third carbon atoms, offers safer alternatives in antifreeze and polymer production.

| Property/Aspect | 2-Methyl-1,3-Propanediol (MPO) | Propylene Glycol (PG) | 1,3-Propanediol (PDO) |

|---|---|---|---|

| Chemical Structure | Contains a methyl group on the second carbon atom of the propane chain | Simple 3-carbon chain with two -OH groups | Simple 3-carbon chain with two -OH groups |

| Molecular Formula | C4H10O2 | C3H8O2 | C3H8O2 |

| IUPAC Name | 2-Methyl-1,3-propanediol | Propane-1,2-diol | Propane-1,3-diol |

| Melting Point (°C) | -40.5 | -59 | -28.6 |

| Boiling Point (°C) | 172.1 | 188.2 | 214.5 |

| Density (g/cm^3) | 0.993 | 1.036 | 1.059 |

| Reactivity | High, used in polymer production | Moderate, used in various applications | Moderate, used in various applications |

| Solubility | Soluble in water and many organic solvents | Highly soluble in water and miscible with most organic solvents | Soluble in water and many organic solvents |

| Applications | Polymer production, solvents, coatings | Food, pharmaceuticals, cosmetics | Solvents, antifreeze, plasticizers |

| Toxicity | Low to moderate toxicity, proper handling required | Generally recognized as safe for use in food and pharmaceuticals | Generally recognized as safe for use in food and pharmaceuticals |

| Environmental Impact | May vary, depending on application and disposal methods | Biodegradable, minimal environmental impact | Biodegradable, minimal environmental impact |

Advantages of the Chinese 2-Methyl-1,3-Propanediol Market

The Chinese 2-Methyl-1,3-propanediol (MPO) market has been witnessing significant growth and development, driven by a combination of factors that underscore its competitive advantages on the global stage. This part explores the key strengths and benefits of the Chinese MPO market, highlighting its position as a leading player in the chemical industry.

Strategic Industry Support

One of the foundational pillars of China’s success in the MPO market is the robust support from the government. Strategic initiatives aimed at bolstering the chemical sector’s growth, including investments in research and development, subsidies for innovation, and favorable policies for chemical manufacturing, have paved the way for advancements in MPO production technologies. This government backing has facilitated the development of a thriving ecosystem for chemical manufacturing, making China a hub for MPO production.

Advanced Manufacturing Capabilities

Chinese manufacturers possess advanced production technologies that enable the efficient and high-quality production of MPO. Leveraging state-of-the-art catalysis, hydrogenation processes, and purification technologies, Chinese companies have optimized the MPO production process, ensuring high purity levels and excellent product quality. These technological advancements not only enhance the competitiveness of Chinese MPO on the global market but also contribute to reducing production costs, making Chinese MPO more affordable.

Scalability and Flexibility

The Chinese MPO market benefits from the scalability of its manufacturing operations. The vast industrial base, coupled with a skilled workforce, allows for the rapid scaling of production to meet increasing global demand. Moreover, manufacturers exhibit a high degree of flexibility in production, capable of adjusting processes and outputs in response to market trends and customer needs. This adaptability ensures a reliable supply of MPO, even amidst fluctuating market conditions.

Extensive Supply Chain Network

China’s well-established and comprehensive supply chain network is a critical advantage in the MPO market. From raw material sourcing to final product distribution, the efficiency of China’s supply chain logistics ensures timely and cost-effective delivery of MPO worldwide. The integration of modern logistics, transportation infrastructure, and digital tracking technologies further enhances the reliability and speed of the supply chain.

Competitive Pricing

The combination of advanced manufacturing technologies, government support, and efficient supply chain management allows Chinese MPO producers to offer competitive pricing without compromising quality. This pricing advantage makes Chinese MPO an attractive option for buyers seeking high-quality diols at lower costs, contributing to China’s growing share in the international market.

Commitment to Sustainability

In recent years, Chinese manufacturers have increasingly focused on sustainability and environmental responsibility in MPO production. Investments in cleaner production technologies, waste management, and emissions reduction initiatives reflect China’s commitment to minimizing the environmental impact of its chemical industry. This focus on sustainability not only aligns with global environmental standards but also appeals to eco-conscious consumers and businesses.

Our Team

FAQs of 2-Methyl-1,3-Propanediol

A1: 2-Methyl-1,3-Propanediol (MPO) is a versatile organic compound used in various industries, including polymer production, cosmetics, and pharmaceuticals. It serves as a key monomer in polyurethane and polyester resin formulations, offering benefits like enhanced durability and chemical resistance.

A2: MPO is extensively used in creating high-performance polyurethanes, durable polyester resins, effective industrial solvents, and in cosmetic and pharmaceutical formulations. Its unique properties make it ideal for products requiring flexibility, stability, and safety.

A3: As a leading supplier of 2-Methyl-1,3-Propanediol (MPO), we pride ourselves on offering a product of unparalleled purity, exceeding 99.5%. Our MPO is rigorously tested to ensure it meets the highest industry standards for quality and performance, guaranteeing optimal results for all applications.

A4: Safety measures include:

Proper Storage: Store MPO in a cool, well-ventilated area away from direct sunlight and heat sources.

Use of PPE: Wear suitable protective clothing, gloves, and eye/face protection when handling MPO.

Spill Management: Familiarize yourself with spill management procedures and have spill kits readily available.

Ventilation: Ensure adequate ventilation in areas where MPO is stored or used to prevent vapor accumulation.

A5: Yes, MPO can be shipped internationally, subject to compliance with international transport regulations for chemicals. Ensure your supplier is familiar with and adheres to these regulations, including proper labeling, packaging, and documentation requirements.

A6: In skincare products, 2-Methyl-1,3-Propanediol (MPO) functions as a potent humectant and solvent. It effectively attracts and retains moisture in the skin, enhancing hydration levels. Additionally, MPO improves product texture and stability, making formulations more pleasant to use.

A7: Absolutely. We offer 100g-200g samples, with the client only covering shipping costs.

A8: Standard lead times are approximately 2-4 weeks, varying based on order size and destination.

A9: Our standard payment terms include a 30% advance and the balance against delivery, but terms can be negotiated for long-term partnerships.

A10: Yes, we offer comprehensive after-sales support, addressing any post-purchase queries or concerns.

A11: As a supplier, in order to provide you with an accurate quote for your product, please inform us of the quantity you require, the required purity specifications, any specific packaging needs, your shipping location, and whether your application requires any customization requirements or certifications.