Sodium Lauryl Ether Sulfate(SLES)

Sodium Lauryl Ether Sulfate (SLES), often regarded as a premier surfactant in various industrial and consumer products, is a substance known for its effective cleaning properties and its role as a foaming agent. This chemical compound, synonymous with its efficiency and versatility, plays a pivotal role in the formulation of numerous personal care and cleaning products worldwide.

Synonyms: SODIUMLAURYLETHERSULFATE;NAXOLATEES-130;NAXOLATEES-230;NAXOLATEES-330;NAXOLATEES-360;Laurylethersulfate,sodiumsalt;Poly(oxy-Chemicalbook1,2-ethanediyl),.alpha.-sulfo-.omega.-hydroxy-,C10-16-alkylethers,sodiumsalts;(C10-C16)Alkylethoxylatesulfuricacid,sodiumsalt

Nature: SLES is an anionic detergent and surfactant found in many personal care products. It is a clear or slightly yellowish liquid, soluble in water, and produces a copious foam. This compound is derived from ethoxylated lauryl alcohol and then sulfated, resulting in a molecule that combines excellent solubility, foaming properties, and mildness to the skin. Its nature as a surfactant allows it to lower the surface tension between ingredients, making it an effective emulsifier and cleaner.

SLES Packaging Information

| SLES packaging | Capacity | 20GP | 40GP |

| drum | 170 kg /drum | total 80 drums, Net 13.6 ton | total 148 drums, Net 25.16 ton |

| IBC drum | 1 ton /IBC drum | total 20 IBC drums, Net 20 ton | total 26 IBC drums, Net 26 ton |

| flexibag | 25 ton /flexibag | 1 flexibag, Net 25 ton | N/A |

| ISO Tank | 25 ton /ISO Tank | 1 ISO Tank, Net 25 ton | N/A |

For SLES, we welcome you to test and check the quality, if you need a sample please contact our sales team to discuss your sample requirements, we believe that our product quality is suitable for the specific application, we provide samples free of charge but the shipping cost will be borne by you.

Applications of SLES

Sodium Lauryl Ether Sulfate (SLES) is a versatile surfactant and detergent found in a multitude of products across various industries. Below, we delve into the specific applications of SLES, detailing each to illuminate its importance in everyday products and industrial processes.

Personal Care Products:

Shampoos and Conditioners: SLES is widely used as a primary surfactant in shampoos and conditioners due to its ability to produce rich foam, effectively remove dirt and oil from the hair and scalp, and leave the hair feeling clean and manageable.

Body Washes and Shower Gels: It is a key ingredient in body washes and shower gels for its cleansing and foaming properties. SLES helps to create a luxurious lather that effectively cleanses the skin without causing excessive dryness.

Facial Cleansers: In facial cleansers, SLES helps to remove makeup, dirt, and impurities from the skin’s surface while maintaining a gentle and non-irritating formulation suitable for daily use.

Household Cleaning Products:

Liquid Dish Soaps: SLES is commonly used in liquid dish soaps for its ability to cut through grease and grime on dishes and utensils. It helps to lift away food residues and leave dishes sparkling clean.

Laundry Detergents: In laundry detergents, SLES acts as a surfactant to disperse soil and stains from fabrics, allowing them to be easily rinsed away during the washing process. It contributes to the overall cleaning efficiency and foaming performance of the detergent.

Industrial and Institutional Cleaners:

Industrial Degreasers: SLES is utilized in industrial degreasers and heavy-duty cleaners for its powerful cleaning properties. It effectively removes oils, greases, and other stubborn contaminants from machinery, equipment, and industrial surfaces.

Car Wash Formulations: It is an essential ingredient in car wash formulations for its ability to produce a rich foam that encapsulates dirt and grime, facilitating their removal during the washing process without scratching the vehicle’s surface.

Pet Care Products:

- Pet Shampoos: SLES is incorporated into pet shampoos for its gentle yet effective cleansing action on pet fur and skin. It helps to remove dirt, oils, and odors while maintaining a pH-balanced formulation suitable for pets’ sensitive skin.

Agricultural Applications:

- Pesticide Formulations: In agricultural applications, SLES is sometimes used as a surfactant in pesticide formulations to improve the spreading and wetting properties of the spray solution. It assists in the uniform distribution of the active ingredients on plant surfaces for better pest control.

Sodium Lauryl Ether Sulfate (SLES) finds widespread use across various industries and applications, including personal care products, household cleaners, industrial degreasers, pet care products, and agricultural formulations. Its versatile properties make it a key ingredient in formulations designed for effective cleaning, foaming, and emulsification. If you have any questions about other specific applications of SLES, please contact our team of experts.

REQUEST A QUOTE FOR MORE DETAILS

Benefits of SLES

The benefits of Sodium Lauryl Ether Sulfate (SLES) are multifaceted and contribute to its widespread use in various personal care and household cleaning products:

Effective Cleansing: SLES is highly efficient at removing dirt, oil, and impurities from surfaces, including skin, hair, and household surfaces. Its surfactant properties enable thorough cleansing, leaving surfaces clean and refreshed.

Rich Foaming: SLES has excellent foaming properties, producing a rich and stable lather when mixed with water. This luxurious foam enhances the sensory experience of using products like shampoos, body washes, and dish detergents.

Emulsification: SLES facilitates the emulsification of oils and water, allowing for effective dispersion of oil-based substances in aqueous solutions. This property is particularly useful in formulations where oil and water need to be mixed evenly, such as creams and lotions.

Compatibility: SLES is compatible with a wide range of other ingredients, including other surfactants and additives. This versatility allows for the formulation of diverse products tailored to specific needs and preferences.

Solubility: SLES is highly soluble in water, ensuring easy incorporation into formulations and uniform distribution throughout the product. Its solubility also contributes to the effectiveness of the product when used in cleaning applications.

Mildness: While SLES is a strong cleanser, it is also relatively mild compared to other surfactants like Sodium Lauryl Sulfate (SLS). This makes it suitable for use in products intended for sensitive skin or frequent use.

Overall, SLES offers a combination of effective cleansing, rich foaming, emulsification, compatibility with other ingredients, solubility, and mildness, making it a versatile and desirable ingredient in a wide range of consumer products.

What's The Difference? SLS vs SLES

SLS (Sodium Lauryl Sulfate) and SLES (Sodium Lauryl Ether Sulfate) are both commonly used surfactants in personal care and household cleaning products, but they differ in their chemical structures and properties. Here’s a breakdown of the key differences between SLS and SLES:

1. Chemical Structure:

- SLS: Sodium Lauryl Sulfate is a simple anionic surfactant consisting of a hydrophilic sulfate (SO4) group attached to a hydrophobic lauryl (C12) chain.

- SLES: Sodium Lauryl Ether Sulfate is a more complex surfactant with an ethoxylation process, where ethylene oxide molecules are added to the lauryl chain before sulfation, resulting in a longer, more flexible ethoxy (CH2CH2O) chain.

2. Foaming Properties:

- SLS: SLS is known for its strong foaming ability and is often used in products where rich lather is desired, such as shampoos and body washes.

- SLES: SLES also exhibits foaming properties but tends to produce a milder, more stable foam compared to SLS. It is commonly used in formulations where a balance between foaming and mildness is desired.

3. Mildness:

- SLS: SLS is considered more harsh and can be drying or irritating to sensitive skin, especially when used in high concentrations or on a regular basis.

- SLES: SLES is generally milder and less irritating than SLS, making it suitable for use in products formulated for sensitive skin or frequent use.

4. Compatibility:

- SLS: SLS may interact negatively with certain ingredients, such as proteins and oils, leading to potential formulation challenges or skin irritation.

- SLES: SLES is more compatible with a wider range of ingredients and is often preferred in formulations where stability and compatibility are important considerations.

5. Applications:

- SLS: SLS is commonly found in a variety of personal care and cleaning products, including shampoos, toothpaste, and household cleaners.

- SLES: SLES is also widely used in personal care and cleaning products but is often chosen for formulations where a milder, gentler surfactant is desired, such as baby products or facial cleansers.

In summary, while both SLS and SLES are effective surfactants used in a wide range of products, SLES offers advantages in terms of mildness, compatibility, and stability, making it a preferred choice for certain formulations, especially those targeted towards sensitive skin or specific product requirements.

Is SLES Good or Bad?

Sodium Lauryl Ether Sulfate (SLES) has often been the subject of debate, with concerns raised about its safety and environmental impact. However, it’s essential to dispel misconceptions and provide evidence-based insights to help consumers make informed decisions about its usage.

Safety Considerations:

- Skin Sensitivity: Contrary to common misconceptions, SLES is generally considered safe for use in personal care products. Numerous studies have shown that when used in appropriate concentrations, SLES is well-tolerated by most individuals and does not cause skin irritation or sensitization.

- Eye Irritation: While SLES may cause mild eye irritation in some cases, formulations containing SLES are carefully balanced to minimize the risk of eye irritation. Proper rinsing can further reduce any potential discomfort.

Environmental Impact:

- Biodegradability: SLES is biodegradable under aerobic conditions, meaning it breaks down naturally in the environment over time. Studies have demonstrated that SLES degrades readily in water, reducing the risk of environmental accumulation.

- Ecotoxicity: Research indicates that SLES exhibits low to moderate levels of ecotoxicity, posing minimal risk to aquatic ecosystems when used as directed. Regulatory agencies, such as the Environmental Protection Agency (EPA), have established guidelines to ensure the safe use of SLES in consumer products.

Responsible Usage:

- Concentration: Like any ingredient, the safety and environmental impact of SLES depend on its concentration in the product formulation. Manufacturers adhere to strict guidelines and regulations to ensure that SLES is used at safe and effective levels.

- Formulation: SLES is often used in conjunction with other ingredients to enhance its efficacy and stability. Formulations are carefully balanced to maximize cleaning performance while minimizing potential risks to human health and the environment.

Conclusion: In conclusion, SLES is a widely used surfactant with a proven track record of safety and efficacy when used responsibly. By dispelling misconceptions and providing evidence-based insights into its safety and environmental impact, we can strengthen SLES as a responsible choice for personal care and household cleaning products. With proper formulation and usage, SLES offers effective cleansing performance without compromising on safety or sustainability.

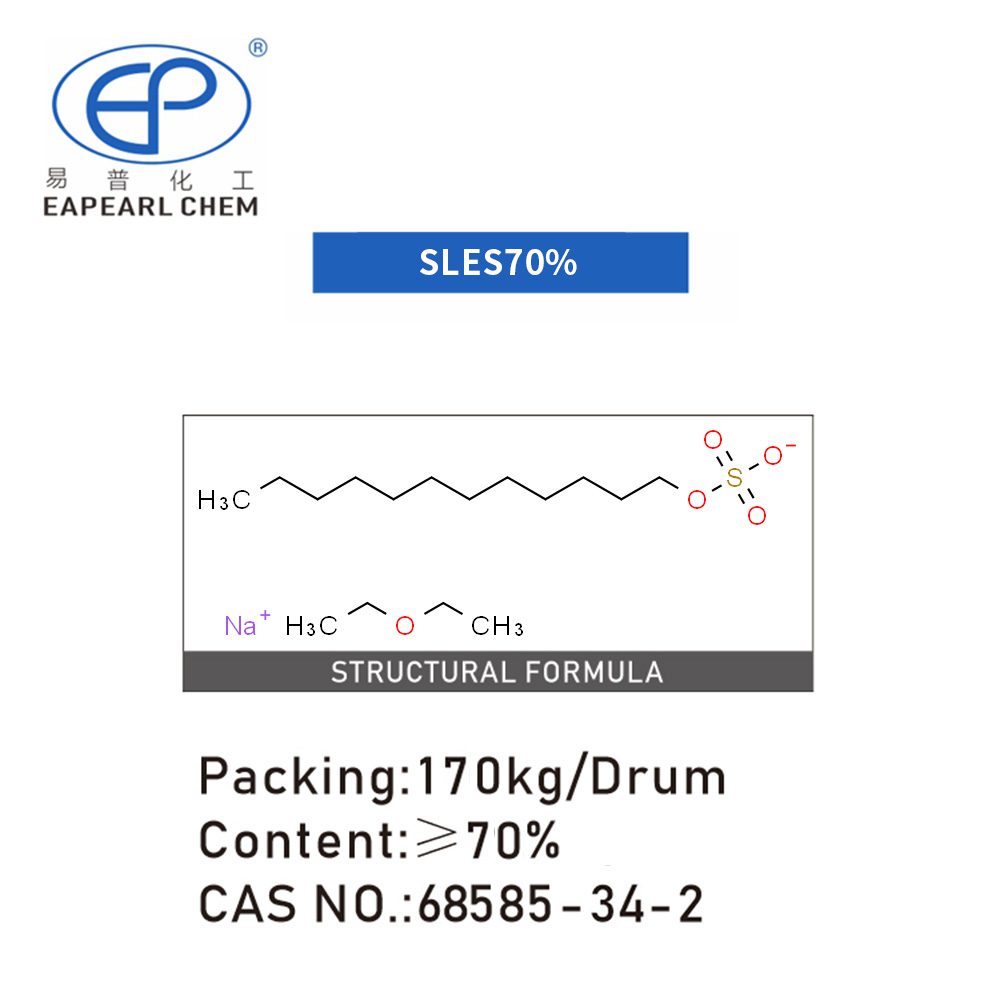

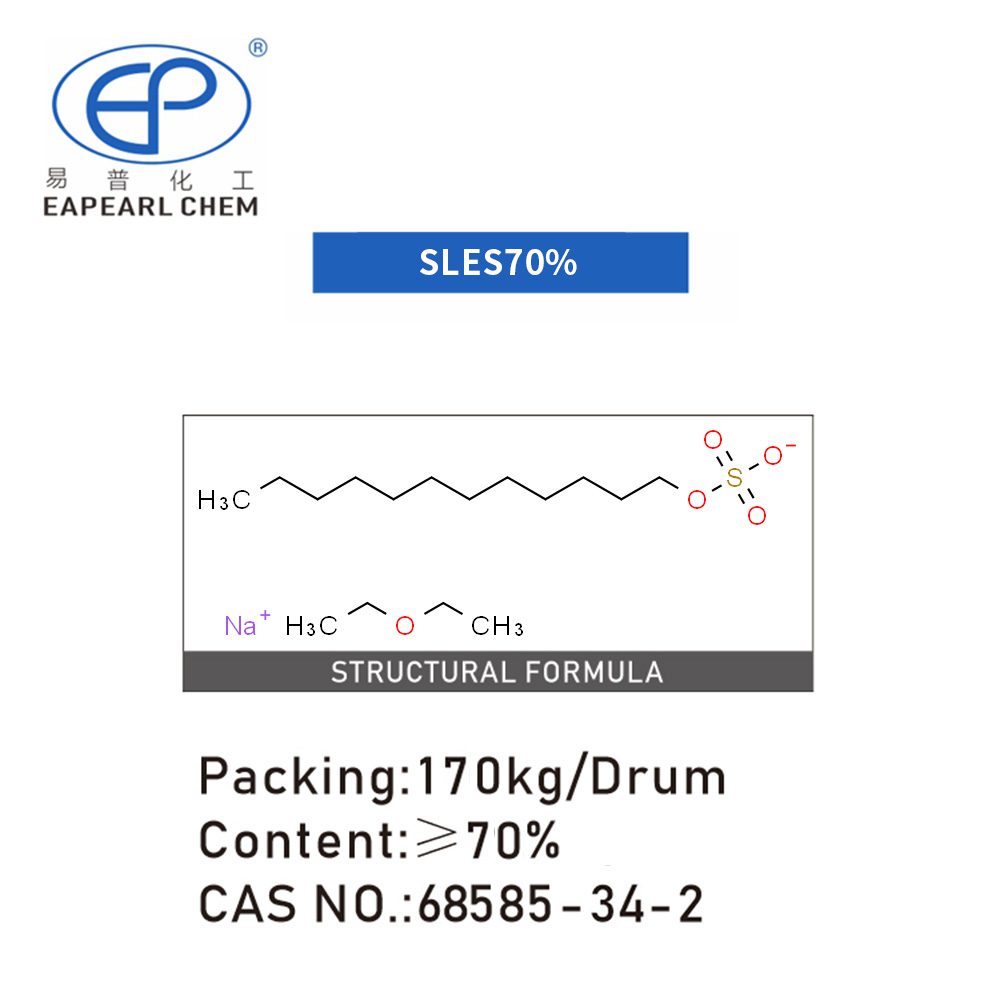

Technical Data of SLES

| Name | Sodium Lauryl Ether Sulfate (SLES) |

| Synonyms | SODIUMLAURYLETHERSULFATE;NAXOLATEES-130;NAXOLATEES-230;NAXOLATEES-330;NAXOLATEES-360;Laurylethersulfate,sodiumsalt;Poly(oxy-Chemicalbook1,2-ethanediyl),.alpha.-sulfo-.omega.-hydroxy-,C10-16-alkylethers,sodiumsalts;(C10-C16)Alkylethoxylatesulfuricacid,sodiumsalt |

| CAS | 68585-34-2 |

| EINECS | 500-223-8 |

| Molecular Formula | C12H26Na2O5S |

| Molar Mass | 328.38 |

| Water Solubility | soluble in hot water |

| Solubility | Chloroform (Slightly), Methanol (Sparingly), Water (Slightly) |

| Appearance | Gel |

| Color | Colourless to Off-White |

| Storage Condition | Hygroscopic, Refrigerator, Under inert atmosphere |

| Stability | Hygroscopic |

| Use | Description: it has excellent decontamination, emulsification and foaming properties, and is easily dissolved in water. As well as favor hard waterproofing and high biodegradation. |

| Application: widely used in shampoo soap, bath shampoo, detergent. It can also be used for spraying and textile industry more clearly. | |

| Application: it has good wetting, emulsifying and cleaning performance. |

Downloadable Documents of SLES

SLES Production

The production of Sodium Lauryl Ether Sulfate (SLES) typically involves several steps, primarily including ethoxylation and sulfation of lauryl alcohol. Here’s a detailed overview of the specific production process:

Production Process of Sodium Lauryl Ether Sulfate (SLES):

1. Ethoxylation:

- Starting Material: The primary starting material for SLES production is lauryl alcohol, which is derived from natural sources such as coconut or palm kernel oil, or synthesized from petrochemicals.

- Ethoxylation Reaction: Lauryl alcohol undergoes ethoxylation, a chemical reaction in which ethylene oxide (EO) molecules are added to the hydroxyl group (-OH) of the lauryl alcohol molecule. This reaction is typically catalyzed by alkaline catalysts such as potassium hydroxide (KOH) or sodium hydroxide (NaOH).

- Formation of Ethoxylates: Ethoxylation results in the formation of a mixture of lauryl alcohol ethoxylates, which are surfactant molecules with varying numbers of ethylene oxide units attached to the lauryl alcohol backbone. The degree of ethoxylation determines the properties of the final SLES product.

2. Sulfation:

- Neutralization: The ethoxylated lauryl alcohol is neutralized with an alkaline substance such as sodium hydroxide (NaOH) or sodium carbonate (Na2CO3) to form a sodium salt.

- Sulfation Reaction: The ethoxylated lauryl alcohol sodium salt is then reacted with sulfur trioxide (SO3) or chlorosulfonic acid (HSO3Cl) to sulfonate the molecule. This sulfation reaction involves the replacement of one of the ethoxy groups with a sulfate group (-OSO3Na).

- Formation of SLES: The sulfation reaction produces Sodium Lauryl Ether Sulfate (SLES), which is the final product of the process. SLES is a mixture of various ethoxylated derivatives of lauryl alcohol with sulfate groups attached, typically containing a range of ethylene oxide units.

3. Purification and Quality Control:

- Neutralization: Any excess sulfur trioxide or chlorosulfonic acid is neutralized with an alkaline solution to ensure the product’s safety and stability.

- Purification: The crude SLES product may undergo purification steps such as filtration, washing, and drying to remove impurities and residual reactants.

- Quality Control: The final SLES product is subjected to rigorous quality control measures to ensure compliance with specifications regarding purity, composition, and performance characteristics.

4. Packaging and Distribution:

- Packaging: The purified Sodium Lauryl Ether Sulfate (SLES) is packaged into containers such as drums, totes, or bulk tanks, depending on the intended use and market requirements.

- Distribution: The packaged SLES is then distributed to various industries and customers for use in formulations of personal care products, household cleaners, industrial applications, and more.

Conclusion:

The production of Sodium Lauryl Ether Sulfate (SLES) involves ethoxylation and sulfation of lauryl alcohol, followed by purification and quality control steps to ensure the final product meets specifications. SLES is a versatile surfactant widely used in diverse applications due to its excellent foaming, cleaning, and emulsifying properties.

REQUEST A QUOTE FOR MORE DETAILS

Advantages of the Chinese SLES Market

In recent years, the Chinese Sodium Lauryl Ether Sulfate (SLES) market has emerged as a pivotal player on the global stage, boasting remarkable growth and resilience. Backed by data from Transparency Market Research, let’s delve into the key advantages that propel the Chinese SLES market forward.

1. Strong Market Growth: The global SLES market, valued at US$ 1.4 billion in 2021, is on a trajectory of robust expansion. Forecasted to grow at a Compound Annual Growth Rate (CAGR) of 4.3% from 2022 to 2031, the market is poised to reach a significant milestone, with an estimated value of US$ 2.0 billion by the end of 2031. This steady growth trajectory positions the Chinese SLES market as a beacon of opportunity amidst a dynamic global landscape.

2. Expansive Consumer Base: With a burgeoning population and a burgeoning middle class, China’s consumer market presents a vast playground for SLES products. The increasing purchasing power and evolving lifestyles of Chinese consumers drive demand for personal care and household cleaning products, where SLES serves as a key ingredient. This burgeoning consumer base offers a fertile ground for market expansion and penetration.

3. Rising Demand for Personal Care Products: The Chinese market’s insatiable appetite for personal care products has propelled the demand for SLES. From shampoos and shower gels to facial cleansers and toothpaste, SLES finds wide-ranging applications in the formulation of these everyday essentials. As Chinese consumers prioritize personal grooming and hygiene, the demand for SLES-infused products continues to soar.

4. Thriving Industrial Landscape: China’s industrial prowess extends to the chemical sector, where SLES production flourishes. Leveraging advanced manufacturing technologies and economies of scale, Chinese SLES manufacturers churn out high-quality products to meet domestic and international demand. This thriving industrial landscape fosters innovation, efficiency, and competitiveness within the Chinese SLES market.

5. Regulatory Compliance and Quality Assurance: China’s regulatory framework for chemical products underscores a commitment to quality and safety standards. Stringent regulations and quality control measures ensure that SLES products meet or exceed industry standards, instilling confidence in consumers and fostering trust in the market. Compliance with regulatory requirements enhances the reputation of Chinese SLES manufacturers and bolsters their competitive edge in the global market.

6. Strategic Investments and Collaborations: Chinese SLES manufacturers are actively engaged in strategic investments and collaborations to fortify their market position. Partnerships with global industry players, investments in research and development, and expansion of production capacities bolster the resilience and competitiveness of the Chinese SLES market. These strategic initiatives position Chinese companies as key players in the global SLES landscape.

In conclusion, the Chinese SLES market stands at the forefront of innovation, growth, and opportunity. With a strong foundation, expansive consumer base, regulatory compliance, and strategic investments, the Chinese SLES market is poised for sustained success and leadership in the global arena. As the market continues to evolve, Chinese SLES manufacturers are well-positioned to capitalize on emerging opportunities and drive future growth.

Our Team

FAQs of SLES

SLES, or Sodium Lauryl Ether Sulfate, is a surfactant commonly used in personal care and household cleaning products. It serves as a foaming agent and emulsifier, helping to remove dirt, oil, and impurities from surfaces.

Yes, when used in accordance with regulations and guidelines, SLES is considered safe for use in personal care products. It undergoes thorough testing to ensure its safety and efficacy.

While SLES is biodegradable under certain conditions, its environmental impact depends on factors such as concentration, usage, and disposal methods. It’s important to use SLES-containing products responsibly and follow proper disposal practices.

While SLES is generally well-tolerated by most individuals, some people with sensitive skin may experience irritation or allergic reactions. It’s advisable to perform a patch test before using products containing SLES, especially for those with known skin sensitivities.

SLES-containing products should be stored in a cool, dry place away from direct sunlight and heat sources. Proper storage helps maintain the stability and effectiveness of the product over time.

SLES is commonly found in a variety of personal care products marketed for infants and children, such as baby shampoos and bubble baths. However, it’s important to choose products specifically formulated for the delicate skin of infants and young children to minimize the risk of irritation.

Absolutely. We offer 100g-200g samples, with the client only covering shipping costs.

Standard lead times are approximately 2-4 weeks, varying based on order size and destination.

Our standard payment terms include a 30% advance and the balance against delivery, but terms can be negotiated for long-term partnerships.

Yes, we offer comprehensive after-sales support, addressing any post-purchase queries or concerns.

As a supplier, in order to provide you with an accurate quote for your product, please inform us of the quantity you require, the required purity specifications, any specific packaging needs, your shipping location, and whether your application requires any customization requirements or certifications.