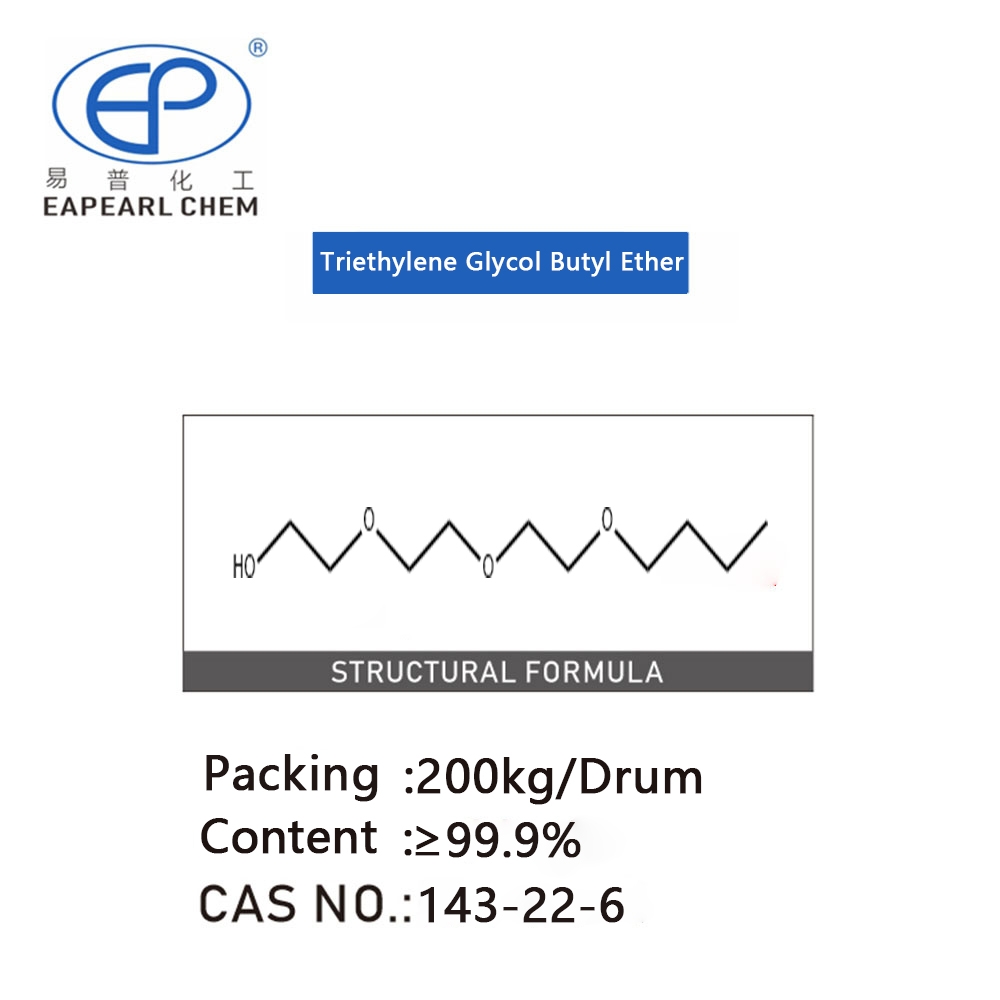

Triethylene Glycol Butyl Ether

Introduction:Triethylene Glycol Butyl Ether (TEGBE) is a multifunctional chemical solvent with applications across various industries. Known for its excellent solvency and compatibility, TEGBE is an essential ingredient for manufacturers seeking reliable performance and quality.

Synonyms :Triethylene Glycol Monobutyl Ether、Butyl Carbitol、Butyl Triethylene Glycol Ether、Ethylene Glycol Butyl Ether Triol、Ethylene Glycol Monobutyl Ether Triol、Ethylene Glycol Butyl Ether Triol、Triglycol Monobutyl Ether、3G3BE (Triethylene Glycol Butyl Ether)、Ethylene Glycol Monobutyl Ether Triol (EGMBE)

Nature and Characteristics:Triethylene glycol monobutyl ether is a colorless to light yellow liquid with low volatility and a slight special odor. It is soluble in many organic solvents, such as alcohols, ethers, esters, etc., and is also miscible with water. It has good surface activity and stability, and can maintain high stability under a variety of conditions. It is usually used as a solvent, plasticizer, and wetting agent, especially in the fields of decorative building materials and paints. It can be used in the formulation of water-based coatings, inks, fiber treatment agents, and can also be used as metal cleaning agents, adhesive components, softeners, detergents, etc.

Triethylene Glycol Butyl Ether Packaging Information

| Triethylene Glycol Butyl Ether Packaging | Capacity | 20GP | 40GP |

| Drum | 200 kg /drum | total 80 drums, Net 13.6 ton | total 148 drums, Net 25.16 ton |

| IBC drum | 860 kg /IBC | total 20 IBC, Net 17.2 ton | total 30 IBC, Net 25.8 ton |

| ISO Tank | 20.5 ton /ISO Tank | 1 ISO Tank, Net 20.5 ton | N/A |

For Triethylene Glycol Butyl Ether, we welcome you to test and check the quality, if you need a sample please contact our sales team to discuss your sample requirements, we believe that our product quality is suitable for the specific application. We provide samples free of charge but the shipping cost will be borne by you.

REQUEST A QUOTE FOR MORE DETAILS

Applications of Triethylene Glycol Butyl Ether

Triethylene glycol butyl ether is an alcohol ether organic compound and an important chemical raw material, widely used in many industries.

Coatings and Paints Industry Applications

TEGBE serves as a solvent in coatings and paints, facilitating uniform application and enhancing durability and corrosion resistance.

- Solvent and Diluent: TEGBE serves as a solvent and diluent in coating formulations, aiding in adjusting viscosity and improving flow characteristics, which ultimately enhances the application properties of coatings.

- Plasticizer: In certain cases, it functions as a plasticizer, enhancing the flexibility and durability of coatings.

- Additive: As an additive, it can improve drying time and surface quality, making coatings more suitable for different application scenarios.

Cleaners Industry Applications

It is employed in industrial and household cleaners for its excellent solvency and stain removal capabilities, particularly effective on metals, glass, and other hard surfaces.

- Degreaser: Due to its excellent solvency and cleaning performance, TEGBE is commonly used as a major component in degreasers, effectively removing oils, dirt, and other surface contaminants.

- Surfactant: In cleaner formulations, it can also act as a surfactant, aiding in better penetration and cleaning of target surfaces.

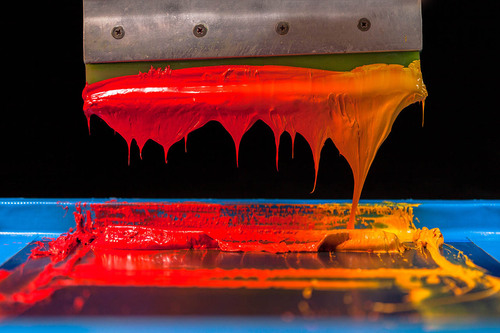

Inks Industry Applications

TEGBE acts as a solvent in printing inks, enhancing drying speed and print quality, suitable for various printing processes.

- Solvent and Modifier: TEGBE is used as a solvent and modifier in ink formulations, helping to increase viscosity and flowability, making it easier for inks to be printed and dried.

- Pigment Dispersant: In some cases, it also serves as a dispersant for pigments, helping to evenly disperse pigments and improve the color stability and quality of printed materials.

Textile and Dye Industry Applications

Used as a textile auxiliary, TEGBE improves dye penetration and dispersion, aiding in even dye distribution and colorfastness.

Agricultural Chemicals Applications

It serves as a solvent in pesticides and herbicides, effectively enhancing their stability and activity.

Cosmetics and Personal Care Products Applications

In cosmetics and personal care products, TEGBE functions as a moisturizer and solvent, improving product texture and feel.

Lubricants Applications

Used in the production of specialty lubricants, TEGBE provides excellent lubricating properties and thermal stability, suitable for high-temperature and demanding environments.

REQUEST A QUOTE FOR MORE DETAILS

Production of Triethylene Glycol Butyl Ether (TEGBE)

Triethylene Glycol Butyl Ether (TEGBE) is produced through the reaction of butanol with triethylene glycol. The process involves etherification, typically catalyzed by acidic catalysts. Here’s an overview of the production process:

1.Raw Materials

- Triethylene Glycol (TEG): A polyether compound used as a precursor.

- Butanol: An alcohol that reacts with TEG to form TEGBE.

- Catalysts: Typically acidic catalysts such as sulfuric acid, p-toluenesulfonic acid, or other strong acids.

2.Production Process

a.Preparation

- Purify triethylene glycol and butanol to remove any impurities that could affect the reaction.

b.Reaction Setup

- The reaction is carried out in a reactor equipped with a heating system, a stirring mechanism, and a condenser.

- Add triethylene glycol and butanol to the reactor in the desired stoichiometric ratios.

- Introduce the acidic catalyst to facilitate the etherification reaction.

c.Etherification Reaction

- Heat the reaction mixture to the required temperature, typically between 120°C to 180°C.

- Maintain constant stirring to ensure uniform mixing of reactants.

- The reaction leads to the formation of TEGBE and water as a by-product.

d.Water Removal

- Continuously remove the water formed during the reaction using a distillation column or a Dean-Stark apparatus.

- Removing water drives the reaction towards completion according to Le Chatelier’s principle.

e.Reaction Completion

- Monitor the reaction progress by sampling and analyzing the reaction mixture using techniques such as gas chromatography (GC) or high-performance liquid chromatography (HPLC).

- Once the reaction is complete, cool the mixture to room temperature.

f.Separation and Purification

- Separate the reaction mixture to remove any unreacted butanol, triethylene glycol, and catalyst residues.

- Purify TEGBE using distillation or other suitable purification techniques to achieve the desired purity level.

g.Quality Control

- Test the final product for purity, composition, and other quality parameters to ensure it meets the required specifications.

- Analytical methods such as GC, HPLC, and spectroscopy can be used for quality control.

By adhering to the outlined production process, TEGBE can be produced efficiently , meeting the quality standards required for its various applications. If you have further questions or need detailed technical support, please feel free to reach out.

The Dangers and Safety Precautions of Triethylene Glycol Butyl Ether

Dangers

Toxicity: TEGBE can cause irritation to the skin, eyes, and respiratory system upon prolonged or repeated exposure. Ingestion or inhalation of high concentrations may lead to adverse health effects.

Flammability: Although TEGBE has a relatively high flash point, it is still flammable and can form flammable vapor-air mixtures. Exposure to ignition sources may result in fire or explosion.

Environmental Impact: Improper disposal or release of TEGBE into the environment can have adverse effects on aquatic organisms and ecosystems due to its low biodegradability.

Safety Precautions

Ventilation: Ensure adequate ventilation in areas where TEGBE is handled to prevent the buildup of vapor concentrations. Use local exhaust ventilation or work in well-ventilated areas.

Personal Protective Equipment (PPE):

Wear appropriate PPE, including chemical-resistant gloves, safety goggles, and protective clothing, to prevent skin and eye contact.

Use respiratory protection, such as a NIOSH-approved respirator, if airborne exposure levels exceed recommended limits.

Handling and Storage:

Avoid contact with skin, eyes, and clothing. In case of contact, immediately remove contaminated clothing and wash skin thoroughly with soap and water.

Store TEGBE in tightly sealed containers in a cool, well-ventilated area away from heat, sparks, and open flames. Keep away from incompatible materials.

Fire Safety:

Keep ignition sources, such as open flames, smoking, and sparks, away from areas where TEGBE is handled or stored.

Use non-sparking tools and equipment to minimize the risk of ignition.

Spill and Leak Response:

In case of spills or leaks, contain the spill to prevent further spread and minimize environmental contamination.

Use absorbent materials, such as vermiculite or sand, to absorb spills. Dispose of contaminated materials properly according to local regulations.

Emergency Procedures:

In the event of a fire, evacuate the area immediately and contact emergency services. Use appropriate fire extinguishing agents, such as foam or carbon dioxide, to extinguish the fire.

In case of accidental ingestion or inhalation, seek medical attention immediately and provide the SDS (Safety Data Sheet) or product label to healthcare professionals.

By following these safety precautions and guidelines, individuals can minimize the risks associated with handling Triethylene Glycol Monobutyl Ether (TEGMBE) and ensure a safe working environment.

REQUEST A QUOTE FOR MORE DETAILS

Advantages of the Chinese Triethylene Glycol Butyl Ether (TEGBE) Market

The Chinese market for Triethylene Glycol Butyl Ether (TEGBE) offers several advantages that make it an attractive option for international buyers and businesses. Here are some key benefits:

1. Cost Competitiveness

- Lower Production Costs:China benefits from lower labor and raw material costs, leading to more cost-effective production of TEGBE compared to many Western countries.

- Economies of Scale: Large-scale production facilities and advanced manufacturing capabilities in China contribute to lower unit costs, providing competitive pricing for TEGBE.

2. Advanced Manufacturing Infrastructure

- Technological Expertise: Chinese chemical manufacturers have invested significantly in modern technologies and infrastructure, ensuring high-quality production processes.

- Large Production Capacity: China’s extensive industrial base allows for large-scale production, meeting the demands of both domestic and international markets efficiently.

3. Quality Assurance

- Strict Quality Control: Many Chinese manufacturers adhere to stringent quality control measures and international standards (such as ISO certification) to ensure the production of high-quality TEGBE.

- Continuous Improvement: Ongoing investments in research and development (R&D) enhance product quality and innovation, maintaining a competitive edge in the global market.

4. Favorable Regulatory Environment

- Government Support: The Chinese government provides substantial support to the chemical industry through favorable policies, subsidies, and incentives, promoting growth and development.

- Regulatory Compliance: Manufacturers comply with international regulations and standards, ensuring that TEGBE produced in China meets global safety and environmental requirements.

5. Strong Supply Chain Network

- Integrated Supply Chain: China’s well-developed supply chain infrastructure ensures reliable and efficient sourcing of raw materials, production, and distribution of TEGBE.

- Logistics and Transportation: Advanced logistics and transportation networks facilitate timely delivery and reduce lead times, ensuring a consistent supply to global markets.

6. Access to Raw Materials

- Abundant Resources: China has abundant resources of raw materials needed for TEGBE production, ensuring a stable and uninterrupted supply chain.

- Local Sourcing: Proximity to raw material sources reduces transportation costs and enhances the overall efficiency of the production process.

7. Strategic Location

- Proximity to Key Markets: China’s geographical location allows easy access to major markets in Asia, Europe, and the Americas, making it a strategic hub for chemical exports.

- Trade Agreements: China has numerous trade agreements and favorable tariffs with various countries, facilitating smoother international trade and export processes.

8. Innovation and R&D

- Research Capabilities: Chinese manufacturers invest in research and development to innovate and improve the efficiency and quality of TEGBE production.

- Collaborations: Partnerships with academic institutions and international research organizations drive technological advancements and product development.

The Chinese market for Triethylene Glycol Butyl Ether (TEGBE) offers numerous advantages, including cost competitiveness, advanced manufacturing infrastructure, quality assurance, a favorable regulatory environment, a strong supply chain network, access to raw materials, strategic location, and innovation in R&D. These factors make China an attractive and reliable source for high-quality TEGBE, catering to the diverse needs of global industries. If you need further details or assistance in sourcing TEGBE from China, please feel free to reach out.

Technical Data of Triethylene Glycol Butyl Ether

| Name | Triethylene Glycol Butyl Ether |

| Synonyms | Triethylene Glycol Monobutyl Ether、Butyl Carbitol、Butyl Triethylene Glycol Ether、Ethylene Glycol Butyl Ether Triol、Ethylene Glycol Monobutyl Ether Triol、Ethylene Glycol Butyl Ether Triol、Triglycol Monobutyl Ether、3G3BE (Triethylene Glycol Butyl Ether)、Ethylene Glycol Monobutyl Ether Triol (EGMBE) |

| CAS | 143-22-6 |

| EINECS | 205-592-6 |

| Molecular Formula | C10H22O4 |

| Density | 0.990 g/mL at 20 °C (lit.) |

| Melting Point | -48°C |

| Boiling Point | 265-350 °C (lit.) |

| Flash Point | 156°C |

| Water Solubility | It is soluble in water. |

| Vapor Presure | 0.02-0.33Pa at 20-24.85℃ |

| Refractive Index | 1.441 |

| Stability | Stablize. Incompatible with acids, strong bases, and strong oxidants. |

| Exterior | Transparent liquid |

FAQs of Triethylene Glycol Butyl Ether (TEGBE)

Triethylene Glycol Butyl Ether (TEGBE) is a multifunctional chemical solvent with applications across various industries. Known for its excellent solvency and compatibility, TEGBE is an essential ingredient for manufacturers seeking reliable performance and quality.

Triethylene glycol monobutyl ether has strong solubility and low toxicity. It is usually used as a solvent, plasticizer, and wetting agent, especially in the fields of decorative building materials and paints. It can be used in the formulation of water-based coatings, inks, fiber treatment agents, and can also be used as metal cleaning agents, adhesive components, softeners, detergents, etc.

Absolutely. We offer 100g-200g samples, with the client only covering shipping costs.

Standard lead times are approximately 2-4 weeks, varying based on order size and destination.

Our standard payment terms include a 30% advance and the balance against delivery, but terms can be negotiated for long-term partnerships.

Yes, we offer comprehensive after-sales support, addressing any post-purchase queries or concerns.

As a supplier, in order to provide you with an accurate quote for your product, please inform us of the quantity you require, the required purity specifications, any specific packaging needs, your shipping location, and whether your application requires any customization requirements or certifications.

How can we handle your order?

step 1

We will communicate with you within 24 hours after you send an enquiry.

step 2

If you need sample testing, we will send samples within 5 days,≤50kg, Express delivery recommended, usually called as DDU service; delivery time 5-7 days. Door to door service.

step 3

If you need bulk goods after the sample test is qualified, we will ship the goods to the port and keep the samples within 6 days after the order is confirmed. Sea shipping recommended, usually called as FOB, CFR, or CIF service.delivery time 10-45 days. Port to port service.

step 4

After waiting for you to receive the goods, we will arrange professional staff to pay a return visit within 7 days.