Reliable Quality & Fast Delivery for Your Business

Ensure Uninterrupted Production with a Reliable Supplier – Delivered On-Time, Every Time

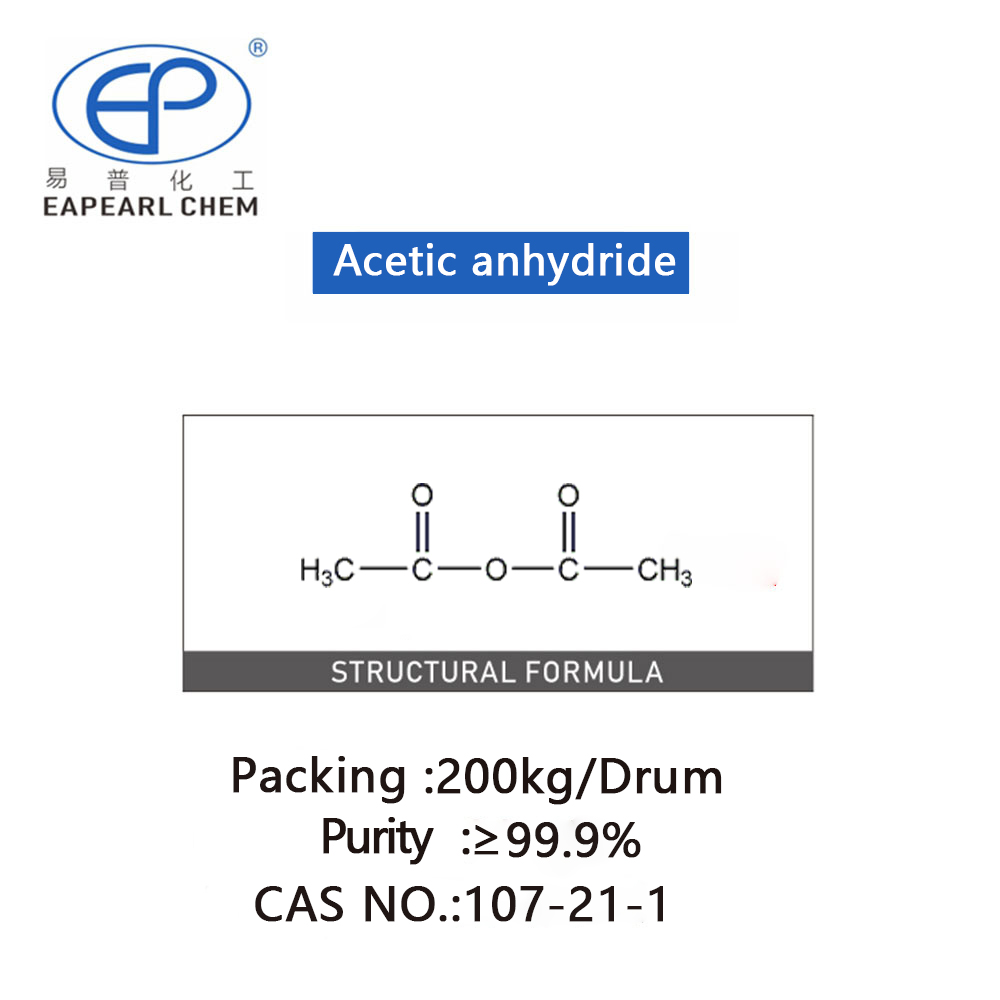

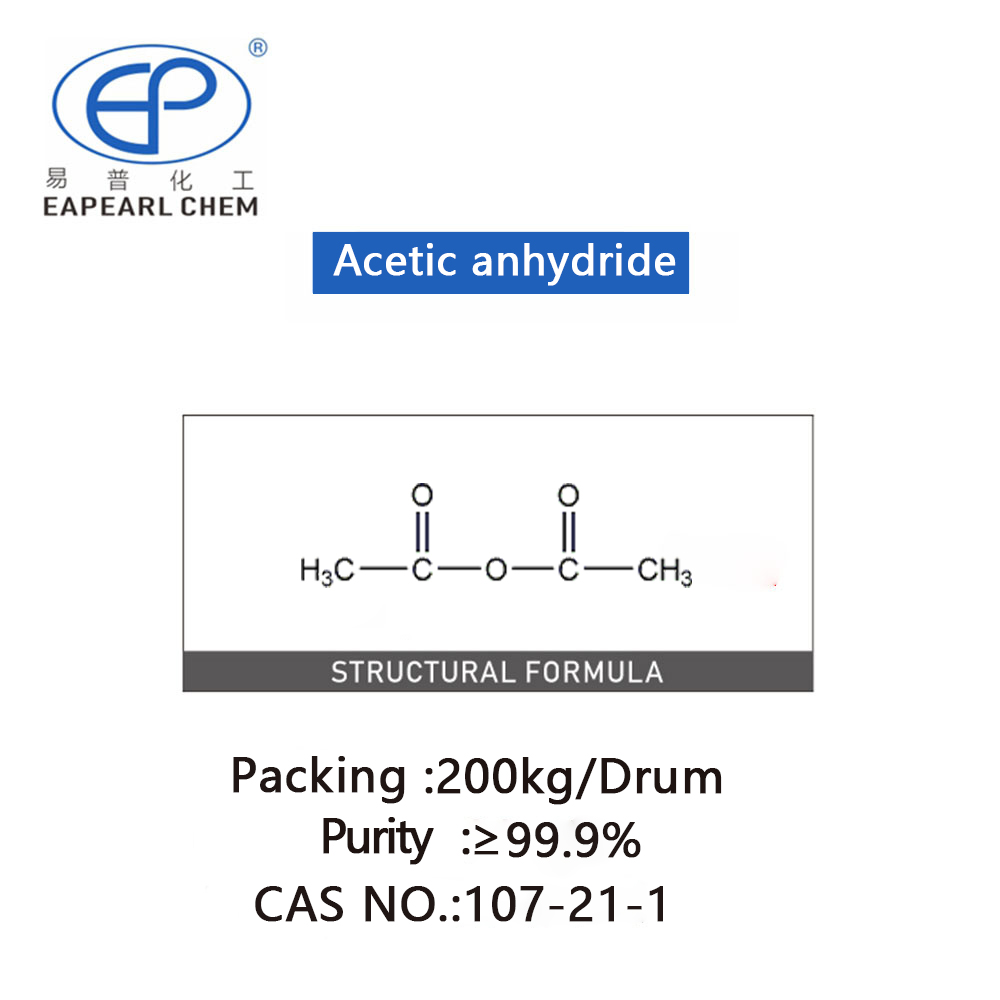

Nature of Acetic Anhydride

Acetic Anhydride, with the chemical formula (CH₃CO)₂O, is an organic compound widely used as a powerful acetylating agent in industrial processes. It is a clear, colorless, and volatile liquid with a strong, pungent odor resembling acetic acid.

- Molecular Weight: 102.09 g/mol

- Boiling Point: 139°C (282°F)

- Melting Point: -73°C (-99.4°F)

- Density: 1.08 g/cm³ at 20°C

- Solubility: Reacts with water, forming acetic acid.

Key Characteristics

a) High Reactivity

Acetic Anhydride readily reacts with alcohols, phenols, and amines to form acetate derivatives.

This makes it essential for chemical synthesis, including pharmaceuticals, resins, dyes, and fragrances.

b) Acetylating Agent

Its strong acetylating properties are critical for producing cellulose acetate (used in textiles and plastics) and acetylsalicylic acid (aspirin).

c) Stability and Storage

Acetic Anhydride is stable under standard storage conditions but requires careful handling to avoid moisture.

Proper storage in sealed containers ensures quality retention.

d) Physical Appearance

Appearance: Colorless, transparent liquid.

Odor: Pungent, acetic odor.

Volatility: Highly volatile and must be handled with proper ventilation.

Acetic Anhydride Packaging Information

| Acetic Anhydride | Capacity | 20GP | 40GP |

| Drum | 200 kg /drum | total 80 drums, Net 13.6 ton | total 148 drums, Net 25.16 ton |

| IBC drum | 860 kg /IBC | total 20 IBC, Net 17.2 ton | total 30 IBC, Net 25.8 ton |

| ISO Tank | 20.5 ton /ISO Tank | 1 ISO Tank, Net 20.5 ton | N/A |

For Acetic Anhydride, we welcome you to test and check the quality, if you need a sample please contact our sales team to discuss your sample requirements, we believe that our product quality is suitable for the specific application. We provide samples free of charge but the shipping cost will be borne by you.

REQUEST A QUOTE FOR MORE DETAILS

How Acetic Anhydride is Used in Various Industries

Acetic Anhydride is a versatile and essential chemical compound that serves as a critical raw material in numerous industries. Its strong acetylating properties make it indispensable in processes requiring high precision and quality.

1. Pharmaceutical Industry

Application: Acetic Anhydride is widely used in the production of Aspirin (acetylsalicylic acid), one of the most commonly used pain-relief and anti-inflammatory drugs.

Other Uses: It is also a key intermediate for synthesizing various active pharmaceutical ingredients (APIs) and drug formulations.

Benefit: High-purity Acetic Anhydride ensures consistent product quality in pharmaceutical manufacturing.

2. Textile Industry

Application: Used to manufacture Cellulose Acetate, a critical component for textiles, fibers, and film applications.

End Products:

Synthetic fibers for apparel and home textiles.

Film bases for photographic films and transparent sheets.

Benefit: Its acetylating properties enhance the durability, luster, and moisture resistance of textile products.

3. Chemical Industry

Application: Acetic Anhydride acts as a key acetylating agent for producing chemical intermediates.

End Products:

Acetate Esters: Used in fragrances, coatings, and adhesives.

Resins and Polymers: Essential for industrial coatings and plastic materials.

Dyes and Pigments: Improves color vibrancy and stability.

Benefit: Reliable quality supports high efficiency and consistent yields in chemical synthesis.

5. Fragrance and Flavor Industry

Application: Essential for creating acetate derivatives, which serve as fragrance ingredients and flavoring agents.

End Products: Perfumes, air fresheners, and flavoring compounds for food and beverages.

Benefit: High-purity Acetic Anhydride ensures the production of safe and high-quality aromatic compounds.

6. Agrochemical Industry

Application: Used to synthesize pesticides and herbicides.

End Products: Crop protection chemicals that enhance agricultural yields.

Benefit: Reliable supply ensures timely production to meet seasonal demand.

7. Explosives Manufacturing

Production of TNT (Trinitrotoluene): Acetic anhydride is used as a precursor in the production of TNT, an essential military-grade explosive.

Summary

Acetic anhydride plays a crucial role in pharmaceuticals, textiles, food, agriculture, chemicals, and explosives production. Its ability to act as an acetylating agent makes it essential for producing high-value intermediates and finished products across multiple industries.

REQUEST A QUOTE FOR MORE DETAILS

The Dangers and Safety Precautions of Acetic Anhydride

While Acetic Anhydride is a critical industrial chemical, its handling requires strict safety measures due to its reactive and hazardous nature. Below is a breakdown of the potential dangers and the necessary precautions to ensure safe usage and storage.

1. Potential Dangers of Acetic Anhydride

a) Health Hazards

- Inhalation: Vapors can cause severe irritation to the respiratory system, leading to coughing, shortness of breath, and potential lung damage with prolonged exposure.

- Skin Contact: Causes burns and irritation upon contact with skin.

- Eye Contact:Can result in severe eye irritation or even permanent damage.

- Ingestion:Harmful if swallowed; may cause damage to the gastrointestinal tract.

b) Environmental Hazards

- Acetic Anhydride reacts with water to form acetic acid, which can harm aquatic life if released into the environment.

- Improper disposal can lead to soil contamination and air pollution.

c) Physical and Chemical Risks

- Highly corrosive to metals.

- Reacts violently with water, alcohols, and bases, producing heat and acetic acid vapors.

- Flammability: Although not highly flammable, vapors may ignite under high temperatures, creating a fire hazard.

2. Safety Precautions for Handling Acetic Anhydride

a) Personal Protective Equipment (PPE)

To ensure worker safety, appropriate PPE must always be worn:

- Respiratory Protection: Use NIOSH-approved respirators in areas with vapor exposure.

- Eye Protection: Chemical safety goggles or a full-face shield.

- Skin Protection: Acid-resistant gloves, long-sleeved protective clothing, and safety boots.

- Ventilation: Use in well-ventilated areas or under local exhaust systems to control vapor concentration.

b) Storage Precautions

- Store in a cool, dry, and well-ventilated area away from heat sources and direct sunlight.

- Keep away from water, alcohols, strong bases, and oxidizing agents to prevent violent reactions.

- Use airtight, corrosion-resistant containers (e.g., stainless steel or HDPE drums).

- Clearly label containers and store them separately from incompatible materials.

c) Handling Guidelines

- Use dedicated equipment and tools when transferring or working with Acetic Anhydride.

- Avoid breathing vapors or allowing skin and eye contact.

- Use spill trays and containment measures when handling large quantities.

- Workers must be trained in safe handling procedures and emergency responses.

3. Emergency Measures

a) In Case of Spills or Leaks

- Evacuate the area and ensure proper ventilation.

- Contain spills using non-reactive absorbents like sand or inert material.

- Avoid water contact; clean up the spill with specialized equipment and dispose of waste properly.

b) First Aid Procedures

- Inhalation: Move the person to fresh air immediately; provide oxygen if breathing is difficult.

- Skin Contact: Wash affected areas thoroughly with water for at least 15 minutes; remove contaminated clothing.

- Eye Contact: Rinse eyes with clean water for at least 15 minutes; seek immediate medical attention.

- Ingestion: Do not induce vomiting; seek emergency medical care.

c) Fire-Fighting Measures

- Use foam, carbon dioxide (CO₂), or dry chemical extinguishers for fires involving Acetic Anhydride.

- Avoid using water, as it can react violently with the chemical.

4. Compliance and Documentation

We provide all necessary safety documents to support proper handling and compliance:

- Material Safety Data Sheet (MSDS)

- Certificate of Analysis (COA)

REQUEST A QUOTE FOR MORE DETAILS

Technical Data of Acetic Anhydride

| CAS No. | 108-24-7 |

| Chemical Name | Acetic anhydride |

| Molecular Formula | C4H6O3 |

| Molecular Weight | 102.09 |

| Melting Point | -73.1 °C |

| Boiling Point | 140 °C |

| Density | 1.087 |

| Vapor Density | 3.5 (vs air) |

| Vapor Pressure | 10mmHg ( 36 °C) |

| Refractive Index | n20/D 1.390(lit.) |

| Flash Point | 130 °F |

| Solubility | Miscible with ether, chloroform and benzene. |

| Form | Liquid |

| Color | Colorless |

| Specific Gravity | 1.082 |

| PH | 3 (10g/l, H2O, 20°C) |

| Odor | Very strong; pungent; vinegar-like characteristic odor. |

| Odor Type | Acidic |

| explosive limit | 2.0-10.2%(V) |

| Water Solubility | REACTS |

| Sensitive | Moisture Sensitive |

| Merck | 14,56 |

| BRN | 385737 |

| Dielectric Constant | 20 |

| Exposure limits | NIOSH REL: ceiling 5 ppm (20 mg/m3), IDLH 200 ppm; OSHA PEL: 5 ppm; ACGIH TLV: ceiling 5 ppm. |

| Stability | Stability Flammable. Incompatible with strong oxidizing agents, water, strong bases, alcohols. |

| LogP | -0.58 at 20℃ |

FAQs of Acetic anhydride

Acetic Anhydride, with the chemical formula (CH₃CO)₂O, is an organic compound widely used as a powerful acetylating agent in industrial processes. It is a clear, colorless, and volatile liquid with a strong, pungent odor resembling acetic acid.

As indicated by its organic chemistry, Ac2O is mainly used for acetylations leading to commercially significant materials. Its largest application is for the conversion of cellulose to cellulose acetate, which is a component of photographic film and other coated materials. Similarly it is used in the production of aspirin (acetylsalicylic acid), which is prepared by the acetylation of salicylic acid.It is also used as a wood preservative via autoclave impregnation to make a longer lasting timber.

In starch industry, acetic anydride is a common acetylation compound, used for the production of modified starches

Because of its use for the synthesis of heroin by the diacetylation of morphine, acetic anhydride is listed as a U.S. DEA List II precursor, and restricted in many other countries.

Absolutely. We offer 100g-200g samples, with the client only covering shipping costs.

Standard lead times are approximately 2-4 weeks, varying based on order size and destination.

Our standard payment terms include a 30% advance and the balance against delivery, but terms can be negotiated for long-term partnerships.

Yes, we offer comprehensive after-sales support, addressing any post-purchase queries or concerns.

As a supplier, in order to provide you with an accurate quote for your product, please inform us of the quantity you require, the required purity specifications, any specific packaging needs, your shipping location, and whether your application requires any customization requirements or certifications.

REQUEST A QUOTE FOR MORE DETAILS

How can we handle your order?

step 1

We will communicate with you within 24 hours after you send an enquiry.

step 2

If you need sample testing, we will send samples within 5 days,≤50kg, Express delivery recommended, usually called as DDU service; delivery time 5-7 days. Door to door service.

step 3

If you need bulk goods after the sample test is qualified, we will ship the goods to the port and keep the samples within 6 days after the order is confirmed. Sea shipping recommended, usually called as FOB, CFR, or CIF service.delivery time 10-45 days. Port to port service.

step 4

After waiting for you to receive the goods, we will arrange professional staff to pay a return visit within 7 days.