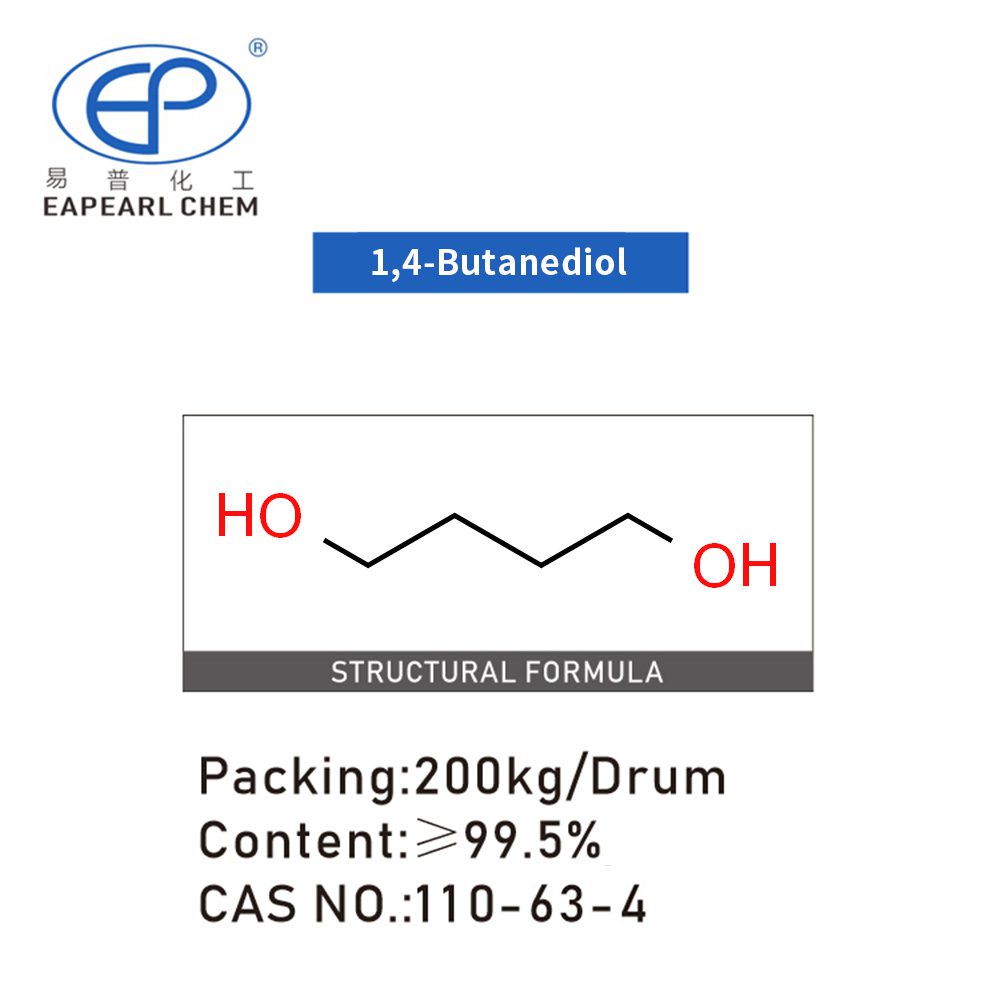

1,4-Butanediol(BDO)

1,4-Butanediol, commonly abbreviated as BDO, is a vital organic chemical compound with the formula C4H10O2. Known for its versatility, BDO is a colorless viscous liquid that plays a crucial role in the production of various industrial and consumer products.

Synonyms:

BDO; butane-1,4-diol; butane-1,1-diol; 1,4-DIHYDROXYBUTANE; 1,4-BUTYLENE GLYCOL; 1,4-Butylene glycol; TETRAMETHYLENE GLYCOL; Tetramethylene glycol; VERSALINK CURATIVE 1,4 BDO; AKOS BBS-00004303;

Nature:

As a diol, 1,4-Butanediol possesses two hydroxyl groups (-OH) attached to its butane backbone, making it highly reactive and a valuable intermediate in chemical synthesis. It is soluble in water and most organic solvents, which contributes to its wide range of applications. The boiling point of BDO is 235 °C, and it has a melting point of 20 °C.

Why Choose Eapearl?

Unmatched Purity and Quality

Our BDO is synthesized through cutting-edge processes, ensuring a product of the highest purity and consistency. Ideal for a wide range of applications, from automotive components to electronic devices, our BDO enhances product durability and reliability.

Sustainability at the Core

We take pride in our sustainable BDO source, minimizing environmental impact while maximizing product efficiency. Our eco-friendly approach ensures that every drop of BDO not only contributes to your product’s performance but also to a greener planet.

Reliable Delivery and Supply

As a reliable 1,4-Butanediol supplier, we guarantee a steady and uninterrupted supply of BDO, ensuring your operations run smoothly without any hiccups. Our logistic solutions are tailored to meet your specific needs, delivering excellence, on time, every time.

Hear from Our Satisfied Customers

Don’t just take our word for it. Explore how businesses across industries have transformed their products with our high-purity BDO. From increased product lifespan to enhanced performance, our customers’ success stories are a testament to our commitment to excellence.

Ready to Transform Your Operations?

Request a Sample Today

Take the first step towards redefining your products with our high-purity, sustainable BDO. Contact us today to request a sample or get a quote, and experience the difference that quality and reliability can make in your operations.

1,4-Butanediol Packaging Information

| BDO Packaging | Capacity | 20GP | 40GP |

| drum | 200 kg /drum | total 80 drums, Net 16 ton | total 128 drums, Net 25.6 ton |

| IBC | 1 ton /IBC | total 20 IBC, Net 20 ton | total 26 IBC, Net 26 ton |

| flexibag | 24 ton /flexibag | 1 flexibag, Net 24 ton | N/A |

| ISO Tank | 24 ton /ISO Tank | 1 ISO Tank, Net 24 ton | N/A |

For 1,4-Butanediol, we welcome you to test and check the quality, if you need a sample please contact our sales team to discuss your sample requirements, we believe that our product quality is suitable for the specific application, we provide samples free of charge but the shipping cost will be borne by you.

Applications of 1,4-Butanediol

Indeed, the versatility of 1,4-Butanediol (BDO) in various industries cannot be overstated. It’s fascinating how this one chemical compound can play such pivotal roles across a broad spectrum of applications. Let’s dive a bit deeper into these uses and understand their importance:

Manufacture of Key Industrial Chemicals

- Tetrahydrofuran (THF): As the backbone for producing THF, BDO’s role is crucial in generating a solvent that’s widely used across different sectors, including as a precursor to polymers and as a solvent in PVC and coatings.

- γ-Butyrolactone (GBL): BDO’s conversion into GBL, which subsequently is used to produce N-methylpyrrolidone (NMP) and other solvents, highlights its importance in applications requiring high-performance solvents for electronics, paint removal, and more.

Polyurethane Production

- BDO is a critical component in the production of polyurethane, which is used in foam products, elastomers, adhesives, and coatings. Polyurethane’s flexibility, durability, and resistance to abrasion and impacts make it essential in automotive interiors, footwear, furniture, and insulation materials.

Thermoplastic Engineering Plastic: PBT Resin

- The application of BDO in manufacturing Polybutylene Terephthalate (PBT) resin underscores its significance in creating high-performance engineering plastics. PBT’s uses in electrical components, automotive parts, and as a material for high-precision mechanical parts highlight BDO’s contribution to advanced manufacturing.

N-Methylpyrrolidone (NMP) and Pyrrolidone Derivatives

- The synthesis of NMP and N-vinylpyrrolidone from BDO points to its role in creating solvents and monomers that are pivotal in pharmaceuticals, polymer production, and electronics. These derivatives are key to producing polymers, fibers, and resins with specialized applications.

Pharmaceutical and Agricultural Applications

- In pharmaceuticals, BDO is used in the synthesis of vitamin B6 and other medicinal compounds, showcasing its utility in health and wellness sectors. Additionally, its use in pesticides and herbicides demonstrates its importance in agriculture, contributing to crop protection and management.

Solvents, Plasticizers, and Lubricants

- BDO’s role as a solvent, plasticizer, and lubricant in various processes reflects its versatility. Its ability to improve the properties of plastics, act as a medium in solvent applications, and enhance lubrication in industrial processes underscores its wide-ranging utility.

Electroplating Industry

- In electroplating, BDO serves as a softener, adhesive, and brightener, improving the quality and durability of electroplated coatings. This application is crucial for enhancing the appearance, corrosion resistance, and surface properties of metal parts.

BDO’s multifaceted applications highlight not just its chemical versatility but also its integral role in supporting and advancing a wide range of industrial and commercial processes. From the synthesis of complex polymers to the enhancement of products in pharmaceuticals, agriculture, and electroplating, BDO’s contributions are foundational to the development of high-quality, durable, and effective products across sectors. Its role in these diverse applications underscores the interconnectedness of modern industry and the essential nature of chemical innovation in driving progress across various fields.

REQUEST A QUOTE FOR MORE DETAILS

Technical Data of 1,4-Butanediol

| Name | 1,4-Butanediol |

| Synonyms | BDO; butane-1,4-diol; butane-1,1-diol; 1,4-DIHYDROXYBUTANE; 1,4-BUTYLENE GLYCOL; 1,4-Butylene glycol; TETRAMETHYLENE GLYCOL; Tetramethylene glycol; VERSALINK CURATIVE 1,4 BDO; AKOS BBS-00004303; |

| CAS | 110-63-4 |

| EINECS | 203-786-5 |

| Molecular Formula | C4H10O2 |

| Molar Mass | 90.12 |

| Density | 1.017 g/mL at 25 °C (lit.) |

| Melting Point | 16 °C (lit.) |

| Boling Point | 230 °C (lit.) |

| Flash Point | 135 °C |

| Water Solubility | Miscible |

| Solubility | Slightly soluble in ether, miscible with water, soluble in ethanol, etc. |

| Vapor Density | 3.1 (vs air) |

| Appearance | Transparent micro viscous liquid |

| Color | Clear colorless |

| Odor | Odorless |

| BRN | 1633445 |

| pKa | 14.73±0.10(Predicted) |

| PH | 7-8 (500g/l, H2O, 20℃) |

| Storage Condition | Store below +30°C. |

| Stability | Stable. Combustible. Incompatible with strong oxidizing agents, mineral acids, acid chlorides, acid anhydrides. |

| Sensitive | Hygroscopic |

| Explosive Limit | 1.95-18.3%(V) |

| Refractive Index | n20/D 1.445(lit.) |

| MDL | MFCD00002968 |

| Physical and Chemical Properties | Colorless oily liquid. |

| melting point 20.2 ℃ | |

| boiling point 228 ℃ | |

| relative density 1.0171 | |

| refractive index 1.4461 | |

| flash point 121 ℃ | |

| solubility is miscible with water. Soluble in methanol, ethanol, acetone, slightly soluble in ether. | |

| HS Code | 29053980 |

| Toxicity | LD50 orally in Rabbit: 1525 mg/kg LD50 dermal Rabbit > 2000 mg/kg |

| LogP | -0.88 at 25℃ |

1,4-Butanediol Production

The production of 1,4-Butanediol (BDO) involves several industrial processes, each with its specific methodologies and chemical reactions. The most common production methods include the Reppe process, the Butadiene process, and the Propylene Oxide process. Here’s a detailed look at each of these specific production processes:

1. Reppe Process

The Reppe process is named after Walter Reppe, a German chemist who developed this method. It involves the catalytic reaction of acetylene with formaldehyde under high pressure and temperature, followed by hydrogenation.

Step 1: Synthesis of Butynediol

Acetylene and formaldehyde are reacted in the presence of a catalyst (usually a base such as sodium or potassium hydroxide) to produce 2-butyn-1,4-diol.Step 2: Hydrogenation

The 2-butyn-1,4-diol undergoes hydrogenation (addition of hydrogen) in the presence of a metal catalyst (such as palladium or nickel) to convert the triple bond into a single bond, resulting in 1,4-Butanediol.

This process is notable for its efficiency and is widely used due to the availability of acetylene, though the cost and safety considerations of handling acetylene can be challenging.

2. Butadiene Process

The Butadiene process starts with butadiene as the main feedstock, which undergoes a series of reactions to produce BDO.

Step 1: Hydroformylation

Butadiene is reacted with synthesis gas (a mixture of carbon monoxide and hydrogen) in the presence of a rhodium or cobalt catalyst to form butyraldehyde via hydroformylation.Step 2: Aldol Condensation

The butyraldehyde then undergoes aldol condensation to form 2-ethylhexenal.Step 3: Hydrogenation

Finally, the 2-ethylhexenal is hydrogenated to produce 1,4-Butanediol. This step also uses a metal catalyst, similar to the Reppe process.

This process is advantageous for its use of butadiene, a readily available by-product of ethylene and propylene production, making it cost-effective for large-scale operations.

3. Propylene Oxide Process

The Propylene Oxide process, also known as the Davy process, involves several steps starting from propylene oxide.

Step 1: Chlorohydrination

Propylene oxide is reacted with hydrochloric acid to produce dichloropropanol.Step 2: Dehydrochlorination

Dichloropropanol is then treated with a base to remove the chlorine atoms, resulting in the formation of allyl alcohol.Step 3: Hydroformylation

Allyl alcohol undergoes hydroformylation with synthesis gas to form 4-hydroxybutyraldehyde.Step 4: Hydrogenation

The final step involves the hydrogenation of 4-hydroxybutyraldehyde to produce 1,4-Butanediol, similar to the final steps in the Reppe and Butadiene processes.

This method is attractive for its use of propylene oxide, a common industrial chemical, and produces BDO alongside other valuable co-products, enhancing overall process efficiency.

REQUEST A QUOTE FOR MORE DETAILS

How can we handle your order?

step 1

We will communicate with you within 24 hours after you send an enquiry.

step 2

If you need sample testing, we will send samples within 5 days,≤50kg, Express delivery recommended, usually called as DDU service; delivery time 5-7 days. Door to door service.

step 3

If you need bulk goods after the sample test is qualified, we will ship the goods to the port and keep the samples within 6 days after the order is confirmed. Sea shipping recommended, usually called as FOB, CFR, or CIF service.delivery time 10-45 days. Port to port service.

step 4

After waiting for you to receive the goods, we will arrange professional staff to pay a return visit within 7 days.

Advantages of the Chinese 1,4-Butanediol Market

The Chinese 1,4-Butanediol (BDO) market stands as a significant player in the global chemical industry, attributed to its extensive production capabilities, innovation, and strategic market positioning. This part explores the advantages of the Chinese BDO market, highlighting its impact on both the domestic and international chemical sectors.

Introduction

1,4-Butanediol (BDO) is a crucial organic compound, widely utilized in the production of plastics, solvents, and synthetic fibers. As a pivotal component in manufacturing polyurethanes, thermoplastic polyurethanes (TPU), and polybutylene terephthalate (PBT), BDO’s global demand has consistently risen. China, as a leading producer and consumer, has developed a robust BDO market characterized by several competitive advantages.

Extensive Production Capacity

China’s significant investment in chemical manufacturing infrastructure has established it as one of the largest BDO producers globally. This extensive production capacity enables the country to meet both domestic and international demand efficiently. The scale of production also allows for competitive pricing, making Chinese BDO attractive in global markets.

Technological Innovation

The Chinese BDO industry is at the forefront of technological innovation, focusing on improving production processes and developing new applications for BDO. Advances in catalysis, process optimization, and environmental sustainability have enhanced production efficiency and product quality. These innovations contribute to reducing production costs and minimizing environmental impact, further strengthening China’s position in the global market.

Strategic Market Positioning

China’s strategic market positioning, bolstered by its vast manufacturing base and growing economy, has made it a key player in the BDO market. The country’s focus on developing high-value applications for BDO in emerging sectors such as biodegradable plastics and renewable energy sources has opened new avenues for growth. Additionally, China’s trade policies and export incentives have facilitated access to international markets, enhancing its global market presence.

Competitive Pricing

The economies of scale achieved by China’s large-scale BDO production, combined with lower labor and overhead costs, contribute to competitive pricing. This pricing advantage enables Chinese BDO producers to capture significant market shares in both developed and developing countries, offering cost-effective solutions without compromising quality.

Supply Chain and Logistics

China boasts a well-developed supply chain and logistics network, ensuring efficient BDO distribution both domestically and internationally. The country’s investment in transportation infrastructure, including ports, railways, and highways, facilitates smooth and timely delivery of BDO to global markets. This logistical efficiency reduces lead times and costs, providing a competitive edge to Chinese BDO suppliers.

Focus on Sustainability

In response to global environmental concerns, the Chinese BDO industry is increasingly focusing on sustainable production methods. Initiatives to reduce waste, lower emissions, and recycle by-products in the BDO production process are gaining momentum. This commitment to sustainability not only addresses environmental regulations but also appeals to environmentally conscious consumers and businesses worldwide.

Our Team

FAQs of 1,4-Butanediol

A1: 1,4-Butanediol is an organic chemical compound, classified as a diol due to its two hydroxyl groups. It’s widely used in the production of polymers, plastics, and solvents. BDO is essential for manufacturing products like polyurethane, thermoplastic polyurethane (TPU), and polybutylene terephthalate (PBT).

A2: BDO must be stored in a cool, dry, and well-ventilated area away from direct sunlight and sources of ignition. Containers should be tightly sealed and made of materials compatible with BDO, such as stainless steel or certain plastics. Safety measures, including spill containment and proper labeling, are mandatory.

A3: 1,4-Butanediol (BDO) is a versatile chemical used primarily in the production of polymers, including polyurethanes, thermoplastic polyurethanes (TPU), and polybutylene terephthalate (PBT). It also serves as an industrial solvent and a precursor to gamma-butyrolactone (GBL), involved in manufacturing various pharmaceuticals and fine chemicals.

A4: 1,4-Butanediol is considered to have low acute toxicity but can be metabolized in the body to gamma-hydroxybutyric acid (GHB), a substance with potentially serious sedative and intoxicating effects. Direct ingestion or improper handling can lead to adverse health effects, necessitating caution and adherence to safety guidelines.

A5: 1,4-Butanediol (BDO) offers numerous benefits, including its versatility in polymer production for creating durable plastics and elastomers. It enhances product performance, ensuring high strength, flexibility, and resistance to chemicals and abrasion. BDO’s application extends to solvents and pharmaceutical intermediates, contributing to various industries’ advancements.

A6: Our 1,4-Butanediol (BDO) is of the highest quality, with a purity exceeding 99.5%. We maintain stringent quality control measures throughout the production process to ensure consistency and reliability. Our BDO is trusted by industries worldwide for its exceptional purity and performance.

A7: Absolutely. We offer 100g-200g samples, with the client only covering shipping costs.

A8: Standard lead times are approximately 2-4 weeks, varying based on order size and destination.

A9: Our standard payment terms include a 30% advance and the balance against delivery, but terms can be negotiated for long-term partnerships.

A10: Yes, we offer comprehensive after-sales support, addressing any post-purchase queries or concerns.

A11: As a supplier, in order to provide you with an accurate quote for your product, please inform us of the quantity you require, the required purity specifications, any specific packaging needs, your shipping location, and whether your application requires any customization requirements or certifications.