Exploring 2-Butanone: A Comprehensive Guide for Informed Decisions

Everything You Need to Know About 2-Butanone

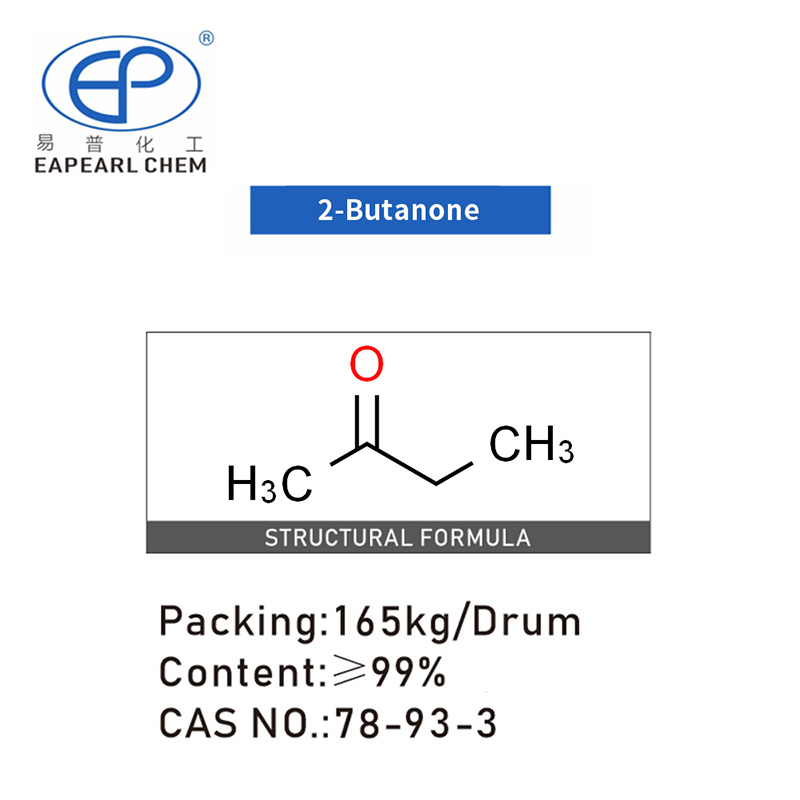

2-Butanone (MEK)

| Product Name | 2-Butanone |

| Common name | 2-Butanone;Butanone;Ethyl methyl ketone;MEK;3-Butanone;Methyl ethyl ketone;Superbutanox M 50 |

| CAS | 78-93-3 |

| EINECS | 201-159-0 |

| Chemical Formula | C4H8O |

| Molecular Weight | 72.11 |

| Purity | ≥99% |

2-Butanone, or methyl ethyl ketone (MEK), is a colorless, flammable liquid with a sharp, sweet odor. It is a solvent of considerable utility in industrial applications.

- Solubility: Miscible with water, alcohol, ether, and organic solvents.

- Chemical Structure: Consists of a four-carbon chain, with a ketone group on the second carbon atom.

- Reactivity: Reactive with solid oxidizers, acids, bases, and can form explosive peroxides.

2-Butanone Packaging Information

Metal Drum

IBC Drum

Flexible Bag

ISO Tank

| DPMA packaging | capacity | 20GP | 40GP |

| drum | 200 kg /drum | total 80 drums, Net 16 ton | total 128 drums, Net 25.6 ton |

| IBC | 1 ton /IBC | total 20 IBC, Net 20 ton | total 26 IBC, Net 26 ton |

| flexibag | 24 ton /flexibag | 1 flexibag, Net 24 ton | N/A |

| ISO Tank | 24 ton /ISO Tank | 1 ISO Tank, Net 24 ton | N/A |

For 2-Butanone, we welcome you to test and check the quality; if you need a sample, please contact our sales team to discuss your sample requirements; we believe our product quality suits the specific application. We provide samples free of charge, but you will bear the shipping cost.

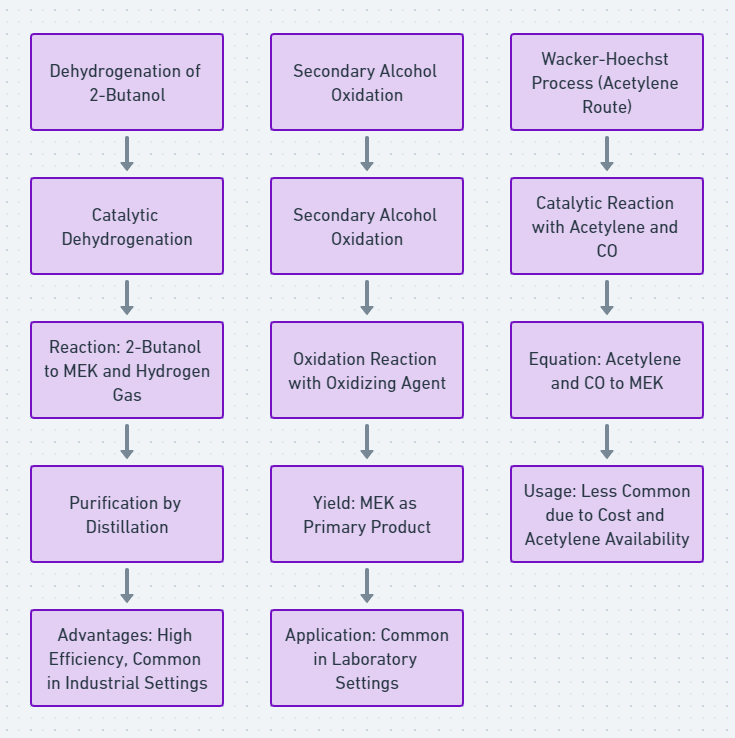

Preparation Method of 2-Butanone

1. Dehydrogenation of 2-Butanol

- Raw Material: The most common method of producing MEK is through the dehydrogenation of 2-butanol.

- Process Steps:

- Catalytic Dehydrogenation: 2-Butanol vapor is passed over a catalyst, typically copper, zinc, or bronze, at high temperatures (about 400°C to 600°C).

- Reaction: CH3CH(OH)CH2CH3→CH3COCH2CH3+H2CH3CH(OH)CH2CH3→CH3COCH2CH3+H2

- The reaction yields MEK and hydrogen gas.

- Purification: The MEK is then separated and purified, typically through distillation.

- Advantages: This method is highly efficient and is the most commonly used process in industrial settings.

2. Secondary Alcohol Oxidation

- Raw Material: Secondary alcohols, including 2-butanol.

- Process Overview:

- Oxidation Reaction: The alcohol is oxidized using a suitable oxidizing agent, such as potassium dichromate in a mixture of dilute sulfuric acid.

- Yield: This process also produces MEK as the primary product.

- Application: This method is more common in laboratory settings than in industrial production.

3. Wacker-Hoechst Process (Acetylene Route)

- Raw Material: This older method uses acetylene and carbon monoxide.

- Process Overview:

- Catalytic Reaction: Acetylene and carbon monoxide react in the presence of a palladium chloride catalyst to form MEK.

- Equation: HCCH+CO→CH3COCH2CH3HCCH+CO→CH3COCH2CH3

- Usage: This method is less common now due to the high cost and less availability of acetylene.

How can we handle your order?

step 1

We will communicate with you within 24 hours after you send an enquiry.

step 2

If you need sample testing, we will send samples within 5 days,≤50kg, Express delivery recommended, usually called as DDU service; delivery time 5-7 days. Door to door service.

step 3

If you need bulk goods after the sample test is qualified, we will ship the goods to the port and keep the samples within 6 days after the order is confirmed. Sea shipping recommended, usually called as FOB, CFR, or CIF service.delivery time 10-45 days. Port to port service.

step 4

After waiting for you to receive the goods, we will arrange professional staff to pay a return visit within 7 days.

2-Butanone Technical Data

| Name | 2-Butanone (MEK) |

| CAS | 78-93-3 |

| EINECS | 201-159-0 |

| Molecular Formula | C4H8O |

| Molar Mass | 72.11 |

| Density | 0.806 g/cm³ 25°C(lit.) |

| Melting Point | -85.9 ℃ |

| Boling Point | 79.6 ℃ |

| Flash Point | -9 ℃(CC) |

| Water Solubility | 290 g/L (20 ºC) |

| Vapor Presure | 9.49kPa(20℃) |

| Appearance | clear liquid |

| Color | Colorless |

| Odor | Smells like acetone |

| Storage Condition | Store below +30°C. |

| Explosive Limit | 1.7%-11.4%(V) |

| Refractive Index | n20/D 1.379(lit.) |

| LogP | 0.3 at 25℃ |

| Toxicity | low toxicity |

| HS Code | 29141200 |

Downloadable Documents of 2-Butanone

REQUEST A QUOTE FOR MORE DETAILS

2-Butanone (MEK) Applications

Solvent in Paints and Coatings

MEK is extensively used as a solvent in paint and coating formulations. It effectively dissolves various resins and polymers, making it ideal for high-performance coatings. In automotive paints, it helps achieve the desired viscosity and evaporation rate, contributing to a smooth, even finish on vehicles. MEK is also prevalent in industrial coatings due to its strong solvency and quick-drying properties.

Adhesive Manufacturing

In adhesive production, MEK dissolves rubber, creating high-strength and flexible adhesives. It’s beneficial in pressure-sensitive adhesives found in tapes and labels. MEK-based adhesives are known for their strong bond and durability, especially in bonding materials like plastics, metals, and composites.

Printing Inks

MEK is crucial in the printing industry, especially flexographic and gravure printing inks. It dissolves ink components effectively, providing the right consistency for printing processes. MEK ensures quick drying and high-quality print on various substrates, including plastics, making it suitable for packaging and labeling.

Cleaning Agent

As a cleaning agent, MEK is employed to degrease and clean machinery, tools, and metal parts. Its ability to dissolve oils, greases, and other contaminants makes it valuable in maintenance and refurbishing. MEK is also used in the electronics industry for cleaning components during manufacturing and repair.

Pharmaceutical Applications

In pharmaceuticals, MEK extracts and purifies certain drugs and pharmaceutical ingredients. Its solvent properties enable the effective extraction of active components, which are vital in producing various medicinal products.

Plastic Welding

MEK is used as a welding agent in the plastics industry, particularly for joining pieces of polystyrene, ABS, and acrylics. It works by dissolving the surfaces of the plastic parts to be joined, forming a solid bond upon evaporation. This application is vital in industries that require the fabrication of plastic components and products.

Electronic Industry

In electronics, MEK is used to clean and degreasing electronic components, especially during assembly. Its effectiveness in removing flux residues and other contaminants ensures the reliability and performance of electronic devices.

REQUEST A QUOTE FOR MORE DETAILS

Market Analysis About 2-Butanone (MEK)

Summary

The global market for Methyl Ethyl Ketone (MEK) is projected to grow from USD 3.8 billion in 2023 to USD 5.9 billion by 2033 at a CAGR of 4.7%. Due to its excellent solvency power and fast evaporation rate, MEK is extensively used as a solvent in various industries, notably in paints, coatings, adhesives, and sealants. It is also used in pharmaceuticals, construction, and automotive industries. The market is driven by growth in construction activities, infrastructural development, and automotive production, especially in emerging economies. However, fluctuations in raw material prices pose challenges.

Supply Dynamics and Production

- Significant Producers: Include China, the United States, and European countries.

- Production Techniques: Primarily produced by dehydrogenation of 2-butanol; also through secondary alcohol oxidation and the Wacker-Hoechst process.

- Raw Material Fluctuations: The cost of production is influenced by the availability and price of raw materials like 2-butanol.

Market Trends

- Environmental Regulations: Increasingly stringent environmental regulations can impact production and use, pushing towards greener alternatives.

- Technological Advancements: Innovations in production processes to reduce environmental impact and improve efficiency.

- Economic Factors: Global economic conditions, including automotive and construction industry health, significantly influence demand.

Regional Market Insights

- Asia-Pacific: The fastest-growing market, primarily due to expanding manufacturing sectors in countries like China and India.

- North America and Europe: Mature markets with steady demand, focusing on environmentally friendly and sustainable production methods.

Future Outlook and Challenges

- Growth Opportunities: Emerging in green solvents and sustainable production methods.

- Challenges: Include managing environmental impact, fluctuating raw material costs, and competition from alternative solvents.

- Market Prediction: Expected to grow moderately, emphasizing balancing industrial needs and environmental concerns.

Conclusion

The 2-butanone market is characterized by its strong demand in key industrial sectors, evolving with technological advancements and regulatory changes. While it faces challenges in terms of environmental impact and raw material costs, the market is expected to adapt and grow, especially in the Asia-Pacific region. Companies in the MEK market are likely to focus more on sustainable practices and innovation to meet global demand while complying with environmental regulations.

Advantages of China's 2-Butanone (MEK) market

The Chinese market stands out in the production of 2-Butanone (MEK) due to its strong manufacturing base and expertise in chemical production. China’s well-developed infrastructure, cost advantages, and economies of scale make it a major player in the global chemical industry. This contributes to its significant market share in MEK production, supported by numerous end-use industries like automotive and construction. The growth of these sectors further drives MEK demand in China.

FAQs of 2-Butanone (MEK)

MEK is primarily used as a solvent in paint thinners, varnishes, and glues and in the production of plastics.

Quality is based on purity levels, the absence of impurities, and formulation consistency.

Raw material costs, manufacturing overheads, and market demand-supply dynamics influence prices.

MEK is a VOC; it can impact air quality and should be used in well-ventilated areas.

Suppliers often provide bulk options but ensure storage capabilities meet safety standards.

Store in a cool, dry place away from heat sources and ensure containers are tightly sealed.

It’s transported in specialized containers under hazardous material regulations.

For purchasing MEK, buyers must have appropriate qualifications to handle hazardous chemicals and adhere to regional regulations. Different regions have specific rules governing the sale and use of dangerous substances, making compliance with these regulations essential. Buyers should be familiar with local and international hazardous chemical purchases and usage laws.

Yes, in limited applications, primarily as a solvent or extraction agent.

Alternatives include acetone, ethyl acetate, and green solvents like methyl coyote.