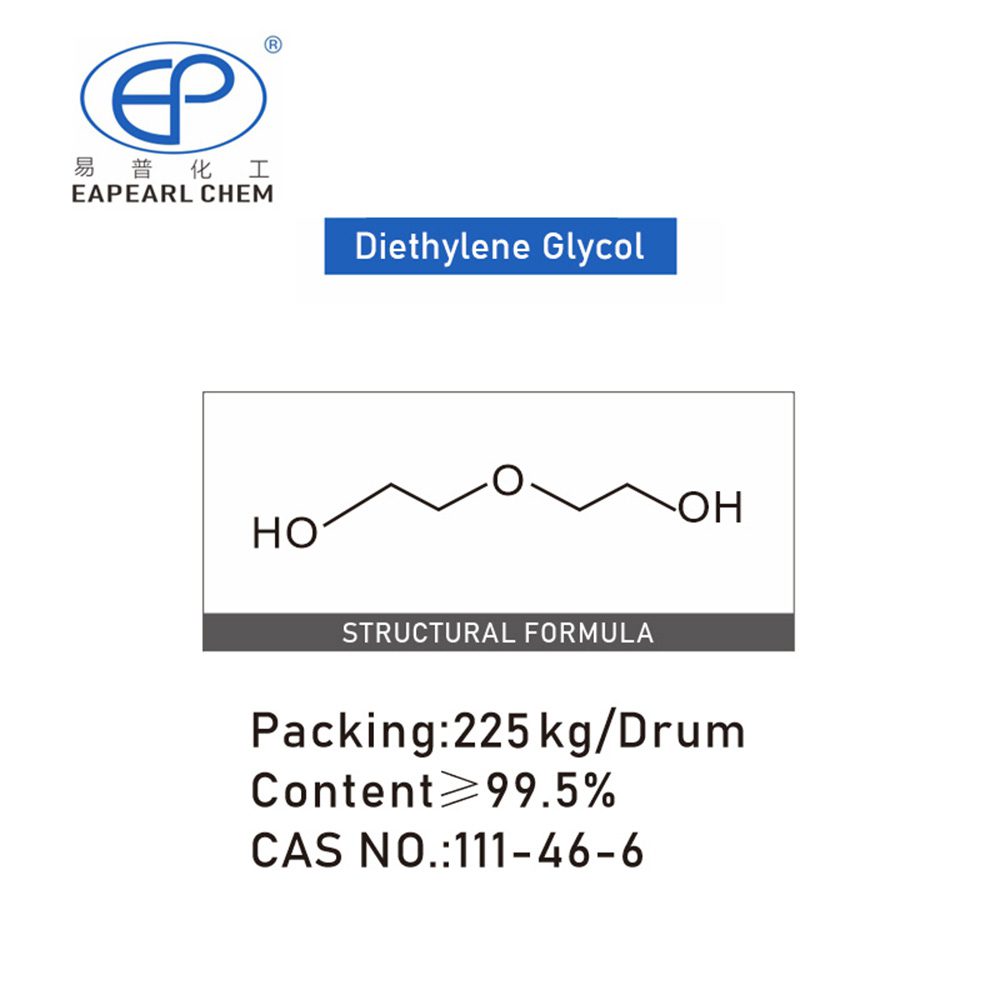

Diethylene Glycol (DEG)

| CAS | 111-46-6 |

| chemical formula | C4H10O3 |

| molecular weight | 106.12 |

| purity | ≥99.5% |

| packing | 225kg/drum |

Are you in search of a chemical solution that can truly elevate your industrial processes? Look no further than Diethylene Glycol (also known as DEG, 2,2′-Oxybis(ethan-1-ol), Diethylene glycol, Ethylene diglycol, Diglycol, 2,2′-Oxybisethanol, Dihydroxy diethyl ether, Digenos, Digol). It’s more than just a chemical, it’s your key to enhanced performance. Ideal as a high-efficiency solvent, a reliable lubricant, and a versatile chemical intermediate, our Diethylene Glycol is tailored for diverse industrial needs.

From optimizing antifreeze formulations in automotive applications to driving advancements in polymer production across the manufacturing sector, DEG seamlessly adapts to your specific requirements. With its exceptional hygroscopic properties and outstanding low-temperature performance, DEG stands as the preferred choice for professionals seeking both efficiency and unwavering reliability.

Eapearl’s Diethylene Glycol (DEG) guarantees a consistently high-quality raw material, what’s even more impressive? Eapearl ensures prompt delivery, eliminating any concerns about supply disruptions. Eapearl offers more than just chemicals, it provides a versatile solution for improving industrial processes. With Eapearl’s 15 years of expertise, commitment to quality, and efficient delivery, partnering with Eapearl is not just a product purchase, but an investment in a solution that will improve your operations and contribute to your long-term success.

Experience the difference with DEG from Eapearl, where versatility meets excellence.

Diethylene Glycol (DEG) Information

| DEG packaging | Capacity | 20GP | 40GP |

| drum | 225 kg /drum | total 80 drums, Net 18 ton | total 108 drums, Net 24.3 ton |

| IBC drum | 1 ton /IBC | total 20 IBC drums, Net 20 ton | total 26 IBC drums, Net 26 ton |

| flexibag | 25 ton /flexibag | 1 flexibag, Net 25 ton | N/A |

| ISO Tank | 25 ton /ISO Tank | 1 ISO Tank, Net 25 ton | N/A |

For diethylene glycol, we welcome you to test and check the quality, if you need a sample please contact our sales team to discuss your sample requirements, we believe that our product quality is suitable for the specific application, we provide samples free of charge but the shipping cost will be borne by you.

How is Diethylene Glycol (DEG) Produced?

The production of diethylene glycol primarily occurs as a by-product in the production of monoethylene glycol (MEG). This process involves several key steps:

Oxidation of Ethylene: The process begins with the oxidation of ethylene. This is done at a high temperature, typically using a silver oxide catalyst. The oxidation of ethylene results in the formation of ethylene oxide, a crucial intermediate in the production of various glycols.

Hydration of Ethylene Oxide: The ethylene oxide then undergoes a hydration process. In this step, the ethylene oxide reacts with water, leading to the formation of different types of glycols. This reaction produces monoethylene glycol (MEG), diethylene glycol (DEG), and triethylene glycol (TEG), among others.

Product Separation: Once the hydration reaction takes place, the different glycols are separated out based on their properties. While the primary aim of this process is often the production of MEG due to its extensive industrial applications, DEG and TEG are valuable by-products.

The chemical industry tends to focus on maximizing the production of MEG because of its high demand in various applications such as in the manufacturing of polyester fibers, polyethylene terephthalate (PET) resins, and antifreeze formulations. However, diethylene glycol also finds its use in a variety of applications, including as a solvent, humectant, a plasticizer, and in the manufacture of unsaturated polyester resins, polyurethanes, and plasticizers. As such, even though it’s a by-product, DEG is a valuable component in the chemical industry.

How can we handle your order?

step 1

We will communicate with you within 24 hours after you send an enquiry.

step 2

If you need sample testing, we will send samples within 5 days,≤50kg, Express delivery recommended, usually called as DDU service; delivery time 5-7 days. Door to door service.

step 3

If you need bulk goods after the sample test is qualified, we will ship the goods to the port and keep the samples within 6 days after the order is confirmed. Sea shipping recommended, usually called as FOB, CFR, or CIF service.delivery time 10-45 days. Port to port service.

step 4

After waiting for you to receive the goods, we will arrange professional staff to pay a return visit within 7 days.

Technical of Diethylene Glycol (DEG)

| Diethylene glycol for short | DEG |

| Molecular Formula | C4H10O3 |

| Molar Mass | 106.12 |

| Density | 1.118g/mLat 25°C(lit.) |

| Melting Point | −10°C(lit.) |

| Boling Point | 245°C(lit.) |

| Flash Point | 143 °C |

| Water Solubility | SOLUBLE |

| Solubility | Miscible with water, insoluble in benzene, toluene, carbon tetrachloride. |

| Vapor Presure | 0.01 mm Hg ( 20 °C) |

| Vapor Density | 2.14 (vs air) |

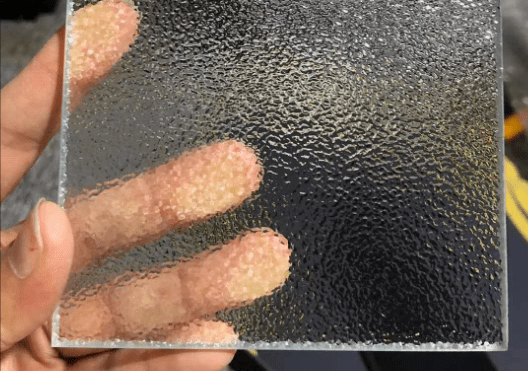

| Appearance | Colorless transparent oily liquid |

| Color | colorless |

| Odor | Practically odorless. |

| Maximum wavelength(λmax) | λ: 260 nm Amax: ≤0.02λ: 280 nm Amax: ≤0.01 |

| Merck | 143,119 |

| BRN | 969209 |

| pKa | 14.03±0.10(Predicted) |

| PH | 5.5-7.0 (25℃, 50mg/mL in H2O) |

| Storage Condition | Keep in dark place,Sealed in dry,Room Temperature |

| Stability | Hygroscopic |

| Sensitive | Hygroscopic |

| Explosive Limit | 2-12.3% |

| Refractive Index | n20/D 1.447(lit.) |

| MDL | MFCD00002882 |

| Physical and Chemical Properties | Appearance colorless or light yellow transparent liquid relative density (d 204) 1.1147~1.1180 boiling point ℃ ≥ 241 boiling range (distilling out 90% by volume)] ℃ ≤ 250 flash point ℃ 141 |

| PSA | 49.7 |

| LogP | -1.98 at 20℃ |

| Toxicity | LD50 in rats, guinea pigs (g/kg): 20.76, 13.21 orally (Smyth) |

| Flammability | this material is combustible, but will not ignite readily |

| HS Code | 29094100 |

| Specific Gravity | 1.1182 |

| EINECS | 203-872-2 |

| explosive limit | 2-12.3% |

Downloadable Documents

COA of DEG

TDS of DEG

MSDS of DEG

REQUEST A QUOTE FOR MORE DETAILS

Diethylene Glycol (DEG) Application

Diethylene glycol is known for its ability to depress the freezing point of substances. This property makes it useful in various applications, including:

- Latex Paint Antifreeze: DEG is used as an antifreeze agent in latex paint to prevent it from freezing at low temperatures.

- Antifreeze: It is a common component in automotive antifreeze formulations to protect engines from freezing during cold weather.

- Heat Transfer Fluids: DEG is used in heat transfer fluids to prevent them from solidifying in low-temperature environments.

Diethylene glycol is used as a chemical intermediate in various industrial processes, including:

- Unsaturated Polyester Resin: DEG is a key component in the production of unsaturated polyester resin, which is used in fiberglass-reinforced plastics and composites.

- Plasticizer Intermediate: It serves as an intermediate for plasticizers used in nitrocellulose lacquers, enamels, and adhesives.

- Polyester Polyols for Urethane Foam: DEG is used in the manufacture of polyester polyols, which are essential for producing urethane foam.

Diethylene glycol is employed as a lubricant in several industries, including:

- Glass-Grinding Aids: DEG acts as a grinding aid in the glass industry, improving the efficiency of glass grinding processes.

- Fiber-Finish Component: It is used as a component in finishes for fibers, enhancing their properties.

- Cement-Grinding Aids: DEG can be added to cement grinding processes to improve the grinding efficiency and quality of cement.

- Mold Release Agent: It is used as a mold release agent in the production of various molded products.

DEG can be used as a solvent and can be used as a solvent coupler. DEG has low volatility, which makes it suitable for applications where low vapor pressure is required such as binder for foundry sand-molding. Diethylene glycol exhibits hygroscopic properties,this property makes it useful in applications like gas dehydration and plasticizer for paper, composition cork, glues, adhesives, bookbinding and coatings.

These diverse characteristics and properties of diethylene glycol make it a versatile chemical compound with a wide range of industrial applications across various sectors. The following table describes the features and applications of DEG.

| DEG characteristics & properties | DEG applications & uses |

| Freezing Point Depression | Latex paint antifreeze |

| Antifreeze | |

| Heat transfer fluids | |

| Drywall joint compound | |

| Belt wetting agent | |

| Chemical Intermediate | Unsaturated polyester resin |

| Plasticizer intermediate for nitrocellulose lacquers, enamels and adhesives | |

| Polyester polyols for urethane foam | |

| Thermoplastic polyurethanes | |

| Emulsifiers | |

| Lubricants | |

| Morpholine | |

| Lubricant | Glass-grinding aids |

| Fiber-finish component | |

| Cement-grinding aids | |

| Mold release agent | |

| Solvent | Aromatic and paraffinic hydrocarbon separations |

| Printing ink/paint pigments/dyes | |

| Solvent Coupler | Stabilizer for soluble oil dispersions |

| Compatibilizer for dye and printing ink components | |

| Low Volatility | Binder for foundry sand-molding |

| Hygroscopicity | Gas dehydration |

| Plasticizer for paper, composition cork, glues, adhesives, bookbinding and coatings |

REQUEST A QUOTE FOR MORE DETAILS

Knowledge Base of Diethylene Glycol (DEG)

Feedback of Diethylene Glycol (DEG)

Nguyen Thi Anh, Vietnam

The purity of diethylene glycol supplied by your company is 99.96%, which meets the specifications provided, and there are no obvious impurities. The product performs satisfactorily as a dehydrating agent in resin production, with efficient dehydrating effects and consistent quality in different batches. The packaging is safe, appropriate and in compliance with Vietnamese regulations. Overall, we are pleased with the quality of diethylene glycol and appreciate the attention to detail in its production and delivery, and look forward to continuing the business relationship.

Arthit Chalermsuk, Thailand

We applied your diethylene glycol to our antifreeze production and the results were immediate and impressive. The chemical stability and efficiency of our antifreeze has been significantly improved, and this formulation improvement has improved the performance of our vehicle cooling systems, ensuring better engine protection and efficiency. This means our customers have reduced maintenance needs, lengthened replacement intervals and reinforced our brand’s commitment to quality and reliability. Your diethylene glycol has not only improved our products, but also had a positive impact on our brand recognition in the market. We are very grateful for your quality products and professional services, and look forward to establishing a long-term and fruitful partnership with your company.

FAQs of Diethylene Glycol (DEG)

What is the difference between diethylene glycol and ethylene glycol?

How is the quality?

The purity of the diethylene glycol products exported by our company has reached more than 99.5%, and the quality is excellent with competitive pricing.

What are the payment options?

You can use Western Union, which has a lower fee, or PayPal if you can accept a slightly higher fee, but please note that for new customers, we only accept the 30% T/T of the payment, or if you have been with us for years and run into cash flow pressure, we do offer OA credit.

How long does it usually take for me to receive the goods?

Depending on the speed of customs clearance and logistics, we can guarantee that the product will be shipped to the port within 5 working days of the order being confirmed, and we have customers in Singapore who receive the goods within 3 weeks.

What is your minimum order quantity for diethylene glycol?

For diethylene glycol, our minimum order quantity is 1 ton. Of course, if you order a large quantity, we can give you a discount on the price.

What information should I let you know if I want to get a quote?

As a supplier, in order to provide you with an accurate quote for your product, please inform us of the quantity you require, the required purity specifications, any specific packaging needs, your shipping location, and whether your application requires any customization requirements or certifications.