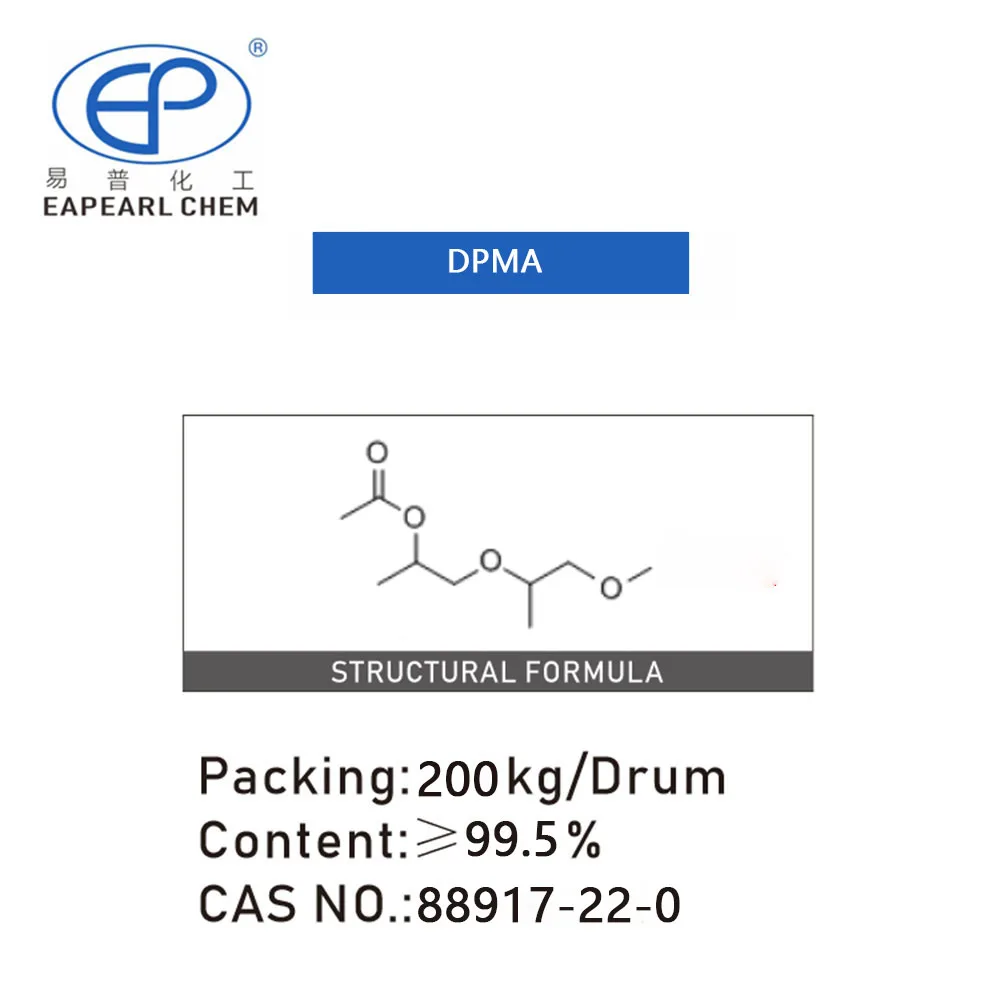

Di(propylene glycol) Methyl Ether Acetate(DPMA)

| Product Name | di(propylene glycol) methyl ether acetate |

| CAS | 88917-22-0 |

| EINECS | 429-830-5 |

| Chemical Formula | C9H18O4 |

| Molecular Weight | 190.24 |

| Purity | ≥99% |

| Grade | industrial grade |

DPMA, alias di(propylene glycol) methyl ether acetate, also know as PD-125944, dowanol dpma, Arcosolv DPMA, DOWANOL(R) DPMA, 1-(3-methoxypropoxy)propyl acetate, Dipropylene glycol monomethyl ether acetate, is a colorless transparent liquid, flammable liquid with a slight ether odor, low toxicity. It has low viscosity, strong solubility, moderate evaporation rate and good coupling ability. It has good solubility to most resins such as acrylic resin, epoxy resin, alkyd resin and polyester resin. Mainly used in inkjet solvent, high solid paint solvent, polyurethane coatings, inks, cleaning agents, solvent based paint and screen printing ink.

Eapearl’s commitment to excellence sets us apart. We guarantee consistently high-quality raw materials and efficient shipping within seven days. Our multi-functional solutions, driven by advanced technology and strict quality control, optimize industrial processes and product quality. Partner with Eapearl for 15 years of expertise, quality, and efficient collaboration that boosts your bottom line and long-term success.

DPMA Packaging Information

| DPMA packaging | capacity | 20GP | 40GP |

| drum | 200 kg /drum | total 80 drums, Net 16 ton | total 128 drums, Net 25.6 ton |

| IBC | 1 ton /IBC | total 20 IBC, Net 20 ton | total 26 IBC, Net 26 ton |

| flexibag | 24 ton /flexibag | 1 flexibag, Net 24 ton | N/A |

| ISO Tank | 24 ton /ISO Tank | 1 ISO Tank, Net 24 ton | N/A |

For DPMA, we welcome you to test and check the quality, if you need a sample please contact our sales team to discuss your sample requirements, we believe that our product quality is suitable for the specific application. We provide samples free of charge but the shipping cost will be borne by you.

Preparation Method of DPMA

The preparation of Di(propylene glycol) methyl ether acetate (DPMA) typically involves chemical processes where reactants are combined under controlled conditions. Here’s a general overview of a common method used to prepare DPMA:

1. Starting Materials

- Reactants: The synthesis of DPMA generally starts with dipropylene glycol methyl ether (DPM) and acetic acid or acetic anhydride as the primary reactants.

- Catalyst: A catalyst may be used to facilitate the reaction. Common catalysts include sulfuric acid or other acid catalysts.

2. Reaction Process

- Esterification or Transesterification:

- In the esterification process, DPM is reacted with acetic acid to produce DPMA and water.

- Alternatively, in transesterification, DPM can be reacted with acetic anhydride, resulting in the formation of DPMA and a by-product, usually acetic acid.

3. Controlling Conditions

- Temperature and Pressure: The reaction is typically carried out under controlled temperature and pressure conditions to optimize the yield and purity of DPMA.

- Reactant Ratios: The ratio of DPM to acetic acid or acetic anhydride is carefully measured to ensure effective conversion to DPMA.

4. Post-Reaction Processing

- Separation and Purification: After the reaction, the mixture is processed to separate DPMA from the other by-products and unreacted materials. This can involve distillation or other separation techniques.

- Quality Control: The final product is tested to ensure that it meets required specifications. Techniques such as gas chromatography (GC), mass spectrometry (MS), and nuclear magnetic resonance (NMR) spectroscopy are often used for this purpose. These techniques are essential in quality control and research settings to ensure the purity, consistency, and desired properties of DPMA.

How can we handle your order?

step 1

We will communicate with you within 24 hours after you send an enquiry.

step 2

If you need sample testing, we will send samples within 5 days,≤50kg, Express delivery recommended, usually called as DDU service; delivery time 5-7 days. Door to door service.

step 3

If you need bulk goods after the sample test is qualified, we will ship the goods to the port and keep the samples within 6 days after the order is confirmed. Sea shipping recommended, usually called as FOB, CFR, or CIF service.delivery time 10-45 days. Port to port service.

step 4

After waiting for you to receive the goods, we will arrange professional staff to pay a return visit within 7 days.

Technical of DPMA

| Name | di(propylene glycol) methyl ether acetate |

| Molecular Formula | C9H18O4 |

| CAS | 88917-22-0 |

| EINECS | 429-830-5 |

| Molar Mass | 190.24 |

| Density | 0.97g/mLat 25°C(lit.) |

| Melting Point | 200℃ |

| Boling Point | 200°C(lit.) |

| Flash Point | 186°F |

| Water Solubility | 183g/L at 20℃ |

| Solubility | 750g/L in organic solvents at 20 ℃ |

| Vapor Presure | 10.4Pa at 20℃ |

| Appearance | Transparent liquid |

| Storage Condition | Room Temprature |

| Sensitive | Easily absorbing moisture |

| Refractive Index | n20/D 1.417(lit.) |

| LogP | 0.61 at 20℃ |

| HS Code | 29153900 |

| Acid Number | ≤0.015 |

| MDL | MFCD00144160 |

| Viscosity | 2.522mm2/s |

Application of DPMA

DPMA is widely used in various industries due to its low odor, low viscosity, strong dissolution ability, moderate evaporation rate and good coupling ability. The following table shows its specific application in these industries and the benefits it provides:

| Industry/Application | Use of DPMA | Benefit |

| Coatings | Solvent in paint and surface coatings | Enhances smoothness and uniformity; improves application properties |

| Ink Manufacturing (especially Silkscreening) | Solvent for ink components | Aids in achieving desired consistency and drying time; improves print quality |

| Adhesives | Solvent in adhesive production | Assists in achieving the right viscosity and bonding characteristics |

| Cleaning Solutions | Cleaning agent for removing oils, greases, etc. | Effective in various cleaning applications due to strong solvent properties |

| Plastics Manufacturing | Plasticizer for producing plastic films, pipes, sheets | Enhances flexibility and processability of plastics |

| Chemical Synthesis | Catalyst carrier in chemical reactions | Increases reaction efficiency and product quality |

| Surfactant Production | Ingredient in manufacturing detergents, emulsifiers, softeners | Enhances cleaning efficiency and fabric care |

| Pharmaceutical Industry | Raw material for synthesizing antibiotics, analgesics; drug adjuvant | Improves drug solubility, bioavailability, and therapeutic effect |

| Cosmetics | Component in hair dye, perfume, lipstick | Enhances skin penetration, moisturizing, and softening effects |

| Industrial Applications | Fuel additive, lubricant, antifreeze | Enhances fuel efficiency, reduces emissions, and protects equipment |

DPMA’s versatility and its benefits across different applications make it a valuable solvent in the chemical industry. It’s particularly noted for its ability to improve product quality, enhance application processes, and provide safer alternatives to more traditional solvents.

If you have specific questions or need more detailed information about any of these applications, feel free to ask. I’m here to provide the insights you need for your business considerations.

REQUEST A QUOTE FOR MORE DETAILS

DPMA Limitations and Future Directions

DPMA has low acute toxicity and its effects depend on the type of exposure. Inhalation of DPMA vapor can cause respiratory irritation, while skin and eye contact can cause irritation and corrosion. Exposure to DPMA has also been associated with liver dysfunction and reproductive system disorders. Due to its toxicity, the application of DPMA in the pharmaceutical industry and DPMA as a solvent is limited. Efforts are under way to find less toxic and more environmentally friendly solvents to replace DPMA.

DPMA has potential applications in various research and industrial fields such as electronics and nanotechnology. It can be used as a solvent to prepare conductive organic polymer films for electronic devices. DPMA can also be used to synthesize nanoparticles for biomedical applications. Although there are many industrial applications, future research should also focus on the potential use of DPMA as a solvent in emerging fields such as nanotechnology and materials science.

DPMA is a versatile solvent that is used in a variety of industrial and scientific experiments. Its physical and chemical properties make it ideal for many applications. However, due to its toxicity and adverse effects on human and environmental health, it must be handled with caution. Researchers and industry players should explore alternative solvents that are less toxic and more environmentally friendly. Overall, DPMA has a promising future as a solvent in various scientific applications and industries.

Why Us

As a supplier of Di(propylene glycol) Methyl Ether Acetate (DPMA), we are proud to highlight several compelling reasons why our product is an exceptional choice for your industrial needs:

Superior Solvent Properties: DPMA is known for its excellent solvency characteristics. This makes it highly effective in a variety of applications, including in coatings, inks, cleaners, and adhesives. Its ability to dissolve a wide range of materials makes it a versatile choice for many industrial processes.

Low Toxicity and Eco-Friendliness: Our DPMA has a lower toxicity profile compared to many other industrial solvents. This aspect is crucial in today’s environmentally conscious market, as it helps in reducing health risks for workers and minimizing environmental impact.

High Boiling Point and Slow Evaporation Rate: The high boiling point and slow evaporation rate of DPMA make it ideal for applications that require a longer working time. This property is particularly beneficial in the coatings industry, where it allows for better flow and leveling of paints and varnishes.

Compatibility with a Wide Range of Materials: DPMA is compatible with many resins and other solvents, which enhances its utility in complex formulations. This compatibility is essential for ensuring the stability and performance of the final product.

Stable Supply Chain and Scalability: We have established a robust and reliable supply chain that ensures consistent availability of DPMA. We are also equipped to scale up production to meet increasing demands, ensuring that we can accommodate your business growth.

Quality Assurance and Compliance: Our DPMA meets stringent quality standards, ensuring that you receive a high-grade product every time. We also adhere to all relevant environmental and safety regulations, providing you with a product that not only meets but exceeds industry standards.

Customized Solutions and Technical Support: We understand that each client has unique needs. Our team is committed to providing customized solutions and technical support to help you integrate our DPMA into your specific industrial processes effectively.

- Cost-Effectiveness: Despite its high quality, our DPMA is competitively priced. This cost-effectiveness, combined with its superior performance, makes it an economically advantageous choice for your business.

By choosing our DPMA, you are opting for a solvent that not only enhances the efficiency and quality of your industrial processes but also aligns with environmental and health safety standards. We are dedicated to providing you with not just a product, but a comprehensive solution that contributes to the success of your business.

Our Team

FAQs of DPMA

A1: Our di(propylene glycol) methyl ether acetate (DPMA) is of the highest quality with a purity greater than 99%, meets stringent industry standards, has consistent purity, excellent solubility and low toxicity for a wide range of industrial applications.

A2: Sure, we’re equipped to handle large-volume orders and guarantee consistent supply. Our robust production capabilities and efficient logistics network enable us to meet high demand while maintaining the quality and reliability that our customers expect.

A3: To ensure consistent availability of our products, we employ a robust supply chain management strategy. This includes maintaining strategic inventory levels, developing strong relationships with reliable suppliers, utilizing advanced forecasting techniques, and implementing efficient logistics solutions. These measures collectively help us respond swiftly to market demands and minimize disruptions, ensuring a steady supply for our customers.

A4: As a supplier, in order to provide you with an accurate quote for your product, please inform us of the quantity you require, the required purity specifications, any specific packaging needs, your shipping location, and whether your application requires any customization requirements or certifications.

A5: Our minimum order quantity for DPMA is 1 ton. We also offer price discounts for large volume orders, providing a cost-effective solution for customers who require large volume orders. Of course, we also provide samples 100g-200g only charge shipping.

A6: The average lead time for the delivery of our products, including DPMA, ranges from 7 to 40 days following order confirmation. This timeframe varies depending on your specific location and the size of your order. We strive to ensure timely and efficient delivery to meet our customers’ needs.