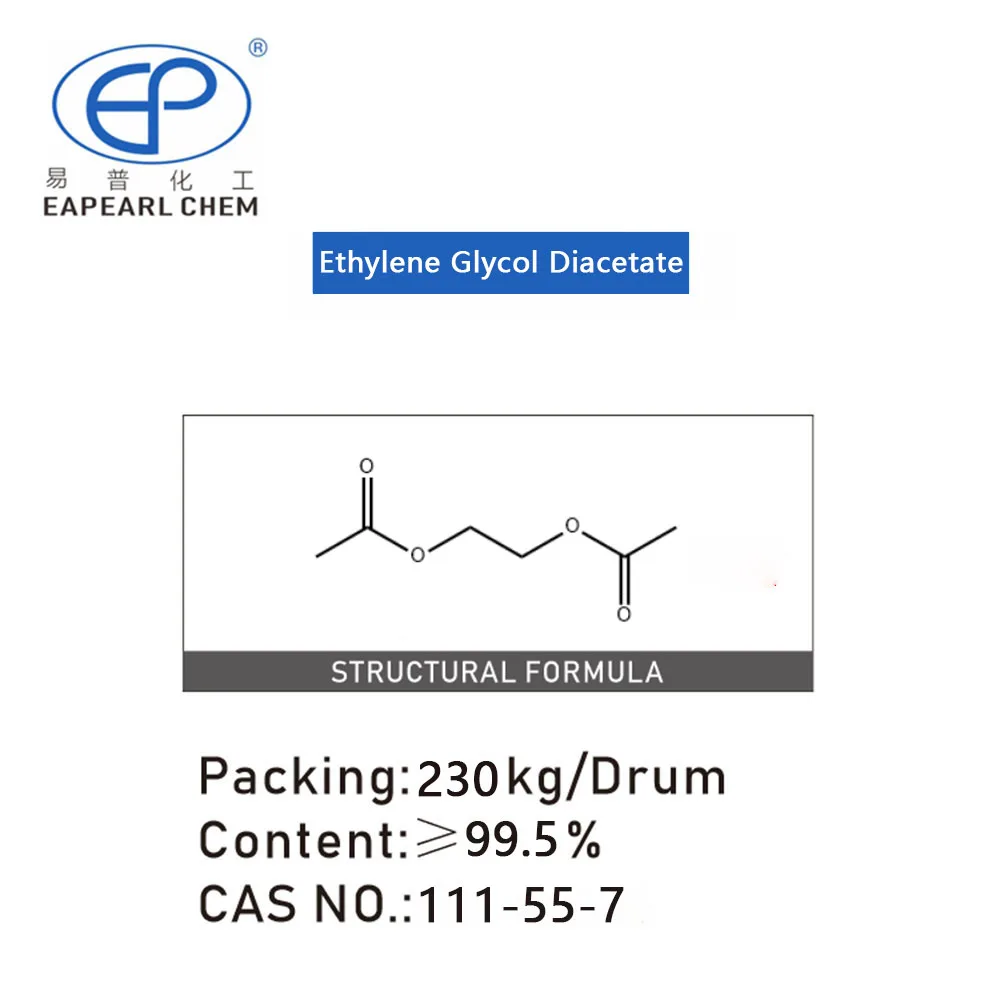

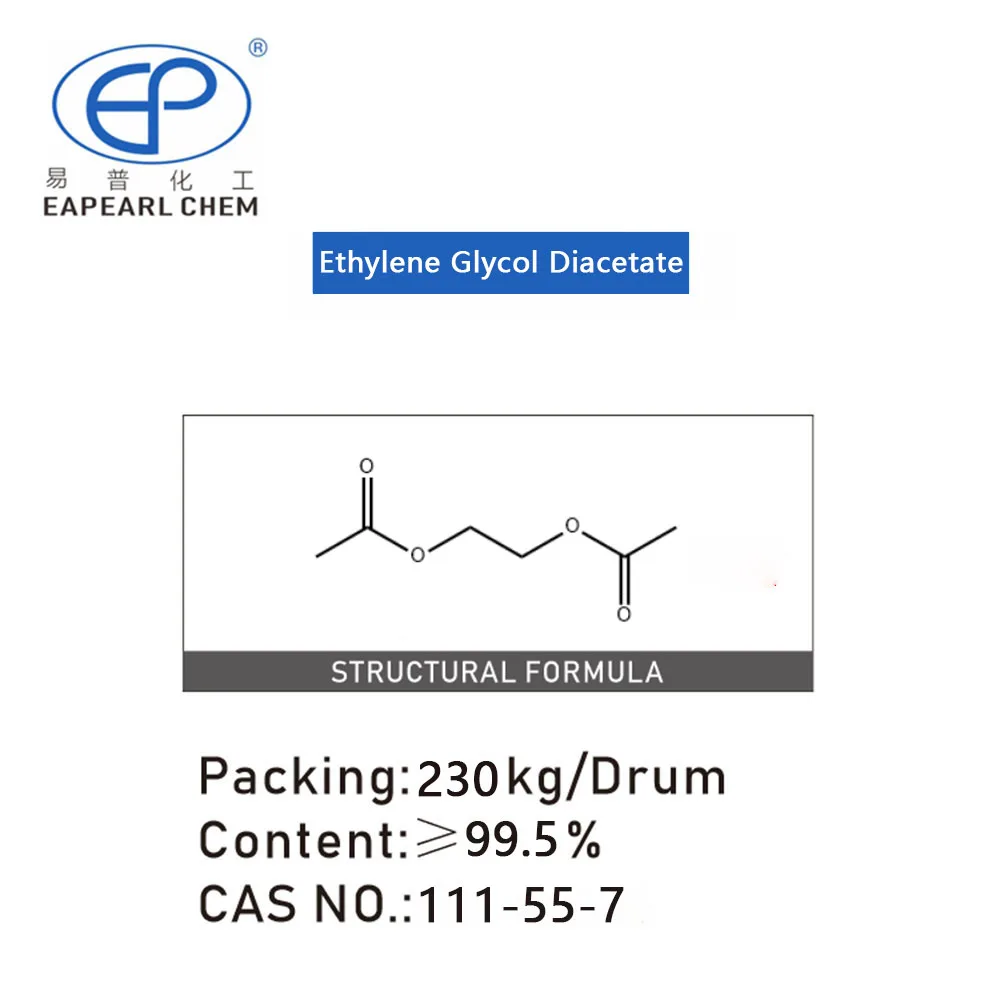

Ethylene Glycol Diacetate(EGDA)

| Product Name | Ethylene glycol diacetate |

| CAS | 111-55-7 |

| EINECS | 203-881-1 |

| Chemical Formula | C6H10O4 |

| Molecular Weight | 146.14 |

| Purity | ≥99.5% |

| Grade | industrial grade |

EGDA full name is ethylene glycol diacetate, short for EGDA, also know as ethylene acetate, ethylene glycol di-acetate, ethylene diacetin, ethylenediethanoate, aceticacid2-acetoxy-ethylester, 1,2-diacetoxyethane, ethylene gycol diacetate, it is a colorless transparent liquid famous for itsenvironmental friendiness and safty property. It is a new generation of environmentally friendly products to replace ethylene glycol butyl ether acetate BGA, dimethyl dioxate DBE, EEP, IBIB, 150#, 200#, propylene glycol methyl ether acetate PMA, DMA, EMA, cyclohexanone CYC, isophorone 783, CAC, ethylene glycol monobutyl ether (anti-white water BCS), diacetone alcohol DAA, and other solvents.

EGDA can be easily dissolved inalcohols , ethers solvent as well as water. EGDA will to be hydrolyse intoalcohol and acetic acid in caustic alkai and inorganic acid. EGDA’s advantageis its low odour , excellent solubility and environmental and safe. EGDA iswildly used in resin industry, paint and coating industry, printing inks,adhesives and chemical intermediates.

Eapearl’s commitment to providing high-quality ethylene glycol diacetate (EGDA) goes beyond just offering a superior chemical product. Our company understands the vital importance of a reliable and consistent supply chain in maintaining the smooth and efficient operations of its clients. When you choose Eapearl’s EGDA, you’re not merely buying a chemical, you’re investing in a comprehensive solution that aims to enhance both your products and processes.

EGDA Information

| EGDA packaging | capacity | 20GP | 40GP |

| drum | 220 kg /drum | total 80 drums, Net 17.6 ton | total 120drums, Net 26.4 ton |

| IBC | 1 ton /IBC | total 20 IBC, Net 20 ton | total 26 IBC, Net 26 ton |

| flexibag | 24 ton /flexibag | 1 flexibag, Net 24 ton | N/A |

| ISO Tank | 24 ton /ISO Tank | 1 ISO Tank, Net 24 ton | N/A |

For EGDA, we welcome you to test and check the quality, if you need a sample please contact our sales team to discuss your sample requirements, we believe that our product quality is suitable for the specific application, we provide samples free of charge but the shipping cost will be borne by you.

Ethylene Glycol Diacetate(EGDA) Preparation Method

The most common synthesis method of Ethylene Glycol Diacetate (EGDA) is the direct esterification of ethylene glycol and acetic acid. The process is generally conducted in the presence of an acid catalyst. Here’s a basic outline of the method:

Reactants:

- Ethylene Glycol (C2H6O2): This is the alcohol component of the reaction.

- Acetic Acid (CH3COOH): The carboxylic acid component.

Reaction Mechanism: In this esterification reaction, the hydroxyl group (OH) of the ethylene glycol reacts with the carboxyl group (COOH) of acetic acid. The reaction results in the formation of EGDA and water as a byproduct.

Catalysis: The reaction is typically catalyzed by an acid. Common catalysts include sulfuric acid or p-toluenesulfonic acid. The catalyst speeds up the reaction by lowering the activation energy required.

Reaction Conditions: The reaction is usually conducted under reflux to maintain the reaction temperature and prevent the loss of reactants. A molar excess of acetic acid is often used to drive the reaction towards the formation of more EGDA.

Purification: After the reaction is complete, the mixture is cooled and the EGDA is separated from the other components. Distillation is commonly employed for this purpose, as EGDA will have a different boiling point than the unreacted ethylene glycol and acetic acid.

Quality Control: The purity and properties of the synthesized EGDA are checked to ensure it meets the desired specifications.

This esterification method is widely used due to its straightforward nature and the relative ease of obtaining the reactants. The direct esterification process is efficient and scalable, making it suitable for industrial production of EGDA.

How can we handle your order?

step 1

We will communicate with you within 24 hours after you send an enquiry.

step 2

If you need sample testing, we will send samples within 5 days,≤50kg, Express delivery recommended, usually called as DDU service; delivery time 5-7 days. Door to door service.

step 3

If you need bulk goods after the sample test is qualified, we will ship the goods to the port and keep the samples within 6 days after the order is confirmed. Sea shipping recommended, usually called as FOB, CFR, or CIF service.delivery time 10-45 days. Port to port service.

step 4

After waiting for you to receive the goods, we will arrange professional staff to pay a return visit within 7 days.

Technical of EGDA

| Molecular Formula | C6H10O4 |

| CAS | 111-55-7 |

| EINECS | 203-881-1 |

| Molar Mass | 146.14 |

| Density | 1.104 g/mL at 20 °C (lit.) |

| Melting Point | -41 °C (lit.) |

| Boling Point | 186-187 °C (lit.) |

| Flash Point | 198°F |

| Water Solubility | 160 g/L (20 ºC) |

| Solubility | 160g/l |

| Vapor Presure | 0.2 mm Hg ( 20 °C) |

| Vapor Density | 5.04 (vs air) |

| Appearance | Colorless liquid |

| Color | blue |

| Odor | at 100.00 %. green floral estery alcoholic |

| Merck | 143,799 |

| BRN | 1762308 |

| MDL | MFCD00008718 |

| Storage Condition | 2-8°C |

| Explosive Limit | 1.6%, 135°F |

| Refractive Index | n20/D 1.431(lit.) |

| Physical and Chemical Properties | Colorless liquid. Melting Point -31 °c, boiling point 190-191 °c, relative density 1.1063(20/20 °c), refractive index 1.4159, flash point 82 °c. With ethanol, ether, benzene miscible, soluble in 7 water. |

| Dielectric constant | 37.7(25℃) |

| LogP | 0.1 at 40℃ |

| Toxicity | LD50 orally in rats: 6.86 g/kg (Smyth) |

| HS Code | 29153900 |

Ethylene Glycol Diacetate(EGDA) Application

Ethylene glycol diacetate (EGDA) has a wide range of applications across various industries due to its solvent properties, compatibility, and environmental friendliness. Here’s a breakdown of its key uses and benefits:

| Industry/Application | Use of EGDA | Benefit |

| Coatings | As a solvent in the production of various types of coatings. | Improves leveling, adjusts the drying rate of paint films, offers faster drying than DBE. |

| Printing Inks | Used in printing inks for its solubility and compatibility. | Enhances ink quality, ensures smooth application. |

| Resin Industry | In the manufacture and processing of resins. | Acts as a safer alternative to more toxic solvents, compatible with various resins. |

| Cleaning Agents | As a component in cleaning products. | Effective in dissolving grime and dirt, non-toxic, and low odor. |

| Cosmetics | Utilized in cosmetic formulations. | Non-toxic and low odor, making it safe and pleasant for personal care products. |

| Pharmaceutical | In pharmaceutical applications. | Safe for use due to non-toxicity, useful as a solvent or carrier. |

| Flavoring Industry | Used in the formulation of spices and flavorings. | Enhances solubility of flavor compounds, non-toxic. |

| Floor and Leather Brighteners | As a solvent in brightening products for floors and leather. | Enhances the appearance, effective in formulation. |

| Electronic Inks | In the production of electronic inks, such as for PCBs. | Ensures consistent quality and application in electronic components. |

| Waterborne Adhesives | Used in water-based adhesive formulations. | Improves adhesive properties, environmentally friendly. |

| Substitution for High Boiling Point Solvents | Partially replaces solvents like cyclohexanone, isophorone, and DBE. | Provides a more environmentally friendly option with lower toxicity. |

EGDA’s diverse applications across these industries underscore its value as a solvent that is not only effective but also aligns with safety and environmental considerations. Its ability to improve product performance and replace more harmful solvents makes it a preferred choice in these sectors.

If you have specific questions or need more detailed information about any of these applications, feel free to ask. I’m here to provide the insights you need for your business considerations.

REQUEST A QUOTE FOR MORE DETAILS

EGDA Market Size Status and Development Trend

The ethylene glycol diacetate (EGDA) market shows promising growth trends and offers various opportunities over the forecast period from 2023 to 2030. The global EGDA market is projected to grow steadily, with a significant compound annual growth rate (CAGR) of 4.5% from 2023 to 2030.

The Asia Pacific region, particularly China, plays a dominant role in the EGDA market, accounting for over 45% of the global market share as of 2019. This is driven by high industrial output and rapid urbanization.

The growth of the EGDA market is mainly driven by increasing demand in industries such as paints and coatings, cosmetics, pharmaceuticals, resins, adhesives, and others. Additionally, growing awareness of the benefits of EGDA over other solvents and stringent environmental regulations regarding VOC emissions are likely to propel market growth. Increased demand from various end-use industries and rising investments for the expansion of production capacities are anticipated to provide further impetus to the market growth during the forecast period.

Overall trends indicate a positive growth trend in the EGDA market, driven by widespread adoption and increasing preference for environmentally friendly solvents.

Why Us

As a supplier of ethylene glycol diacetate (EGDA), there are several compelling reasons why our product stands out and represents an excellent choice for your industrial needs:

Superior Quality: Our EGDA is produced to the highest standards, ensuring consistent purity and performance. This superior quality makes it ideal for a wide range of applications, providing reliability and excellence in results.

Eco-Friendly and Safe: One of the key features of our EGDA is its environmental friendliness and safety. It is less harmful than many traditional solvents, making it a responsible choice for businesses looking to reduce their environmental impact and prioritize worker safety.

Versatile Applications: Our EGDA is incredibly versatile, suitable for use in various industries such as coatings, inks, adhesives, pharmaceuticals, and resins. This versatility allows it to serve as a multifunctional solvent, meeting diverse industrial requirements.

Enhanced Performance Characteristics: Our EGDA offers improved performance features like better leveling, enhanced gloss, and optimal drying speed in coatings and paints. This enhances the quality and finish of your products.

Cost-Effective Solution: We offer EGDA at a competitive price, making it a cost-effective solution without compromising on quality. This affordability, combined with its high performance, provides excellent value for your investment.

Reliable Supply Chain: We understand the importance of a dependable supply chain in industrial operations. Our robust logistics and supply chain management ensure timely and consistent delivery of our EGDA, helping you maintain smooth and uninterrupted production.

Technical Support and Expertise: Our team possesses extensive knowledge about EGDA and its applications. We provide comprehensive technical support and guidance to help you maximize the benefits of our product in your specific processes.

Regulatory Compliance: Our EGDA meets all relevant safety and environmental regulations, ensuring that your operations remain compliant with industry standards and legal requirements.

- SGS CANEC1412847502 Report conclusion: Based on the tests carried out on the samples submitted, the results of the tests for cadmium, lead, mercury, chromium VI, polybrominated biphenyles (PBBs), polybrominated diphenyl ethers (PBDEs) comply with the EU ROHS Directive 2002/95/EU reformulated 2011/65/EUI I Appendix limit requirements.

Choosing our EGDA means investing in a product that delivers in terms of quality, performance, environmental responsibility, and value, backed by a supplier committed to your success.

Our Team

FAQs of EGDA

A1: As a supplier, we pride ourselves on offering top-quality ethylene glycol diacetate(EGDA). Our product undergoes strict quality control and adheres to high manufacturing standards, ensuring consistent purity and performance. We ensure compliance with all relevant regulations, providing our clients with a reliable, high-grade solvent for various applications.

A2: Sure, we’re equipped to handle large-volume orders and guarantee consistent supply. Our robust production capabilities and efficient logistics network enable us to meet high demand while maintaining the quality and reliability that our customers expect.

A3: EGDA solvent offers several key advantages: It’s environmentally friendly, presenting a safer alternative to more harmful solvents. With its excellent solubility in water, alcohols, and ethers, EGDA is highly versatile for various industrial applications. It features a low odor, enhancing workplace comfort. EGDA also boasts superior chemical stability, ensuring consistent performance. Its capacity to improve paint film quality, such as leveling and gloss, along with cost-effectiveness, makes it a preferred choice in many sectors.

A4: To ensure consistent availability of our products, we employ a robust supply chain management strategy. This includes maintaining strategic inventory levels, developing strong relationships with reliable suppliers, utilizing advanced forecasting techniques, and implementing efficient logistics solutions. These measures collectively help us respond swiftly to market demands and minimize disruptions, ensuring a steady supply for our customers.

A5: Our minimum order quantity for EGDA is 1 ton. We also offer price discounts for larger volume orders, providing a cost-effective solution for customers needing bulk quantities.

A6: The average lead time for the delivery of our products, including EGDA, ranges from 7 to 40 days following order confirmation. This timeframe varies depending on your specific location and the size of your order. We strive to ensure timely and efficient delivery to meet our customers’ needs.

A7: As a supplier, in order to provide you with an accurate quote for your product, please inform us of the quantity you require, the required purity specifications, any specific packaging needs, your shipping location, and whether your application requires any customization requirements or certifications.