Ethylene carbonate

Discover the unparalleled versatility and efficiency of ethylene carbonate in powering today’s and tomorrow’s industries. From revolutionizing lithium-ion batteries to being a cornerstone in high-performance solvents, ethylene carbonate stands at the forefront of chemical innovation.

What is Ethylene Carbonate?

Ethylene carbonate, often referred to by its aliases such as ethylene glycol carbonate or 1,3-dioxolan-2-one, is a notable organic compound with the molecular formula (CH2O)2CO. This ester of ethylene glycol and carbonic acid is characterized by its clear to yellowish color and a somewhat sweet odor, reminiscent of esters. Its physical state at room temperature is solid, indicating its distinct nature among carbonate esters.

Ethylene carbonate is a high-value organic compound known for its exceptional solvency and electrolyte formulation capabilities. Produced through the reaction of ethylene oxide and carbon dioxide, this compound is pivotal in numerous applications, including but not limited to, advanced energy storage and polymer production.

Nature and Properties

Ethylene carbonate is known for its exceptional solvency and high dielectric constant, making it highly soluble in water and capable of dissolving a wide range of polar organic compounds. Its boiling point is remarkably high, at approximately 248°C (478°F), which underscores its stability under elevated temperatures. The compound’s chemical structure, featuring a cyclic carbonate group, is instrumental in its reactivity and application spectrum.

Table of Contents

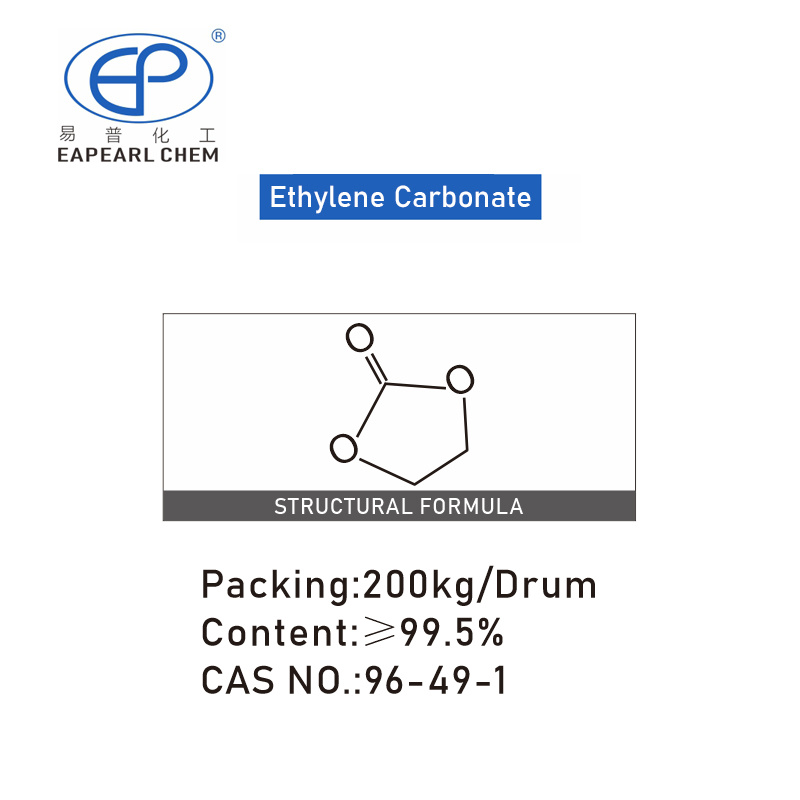

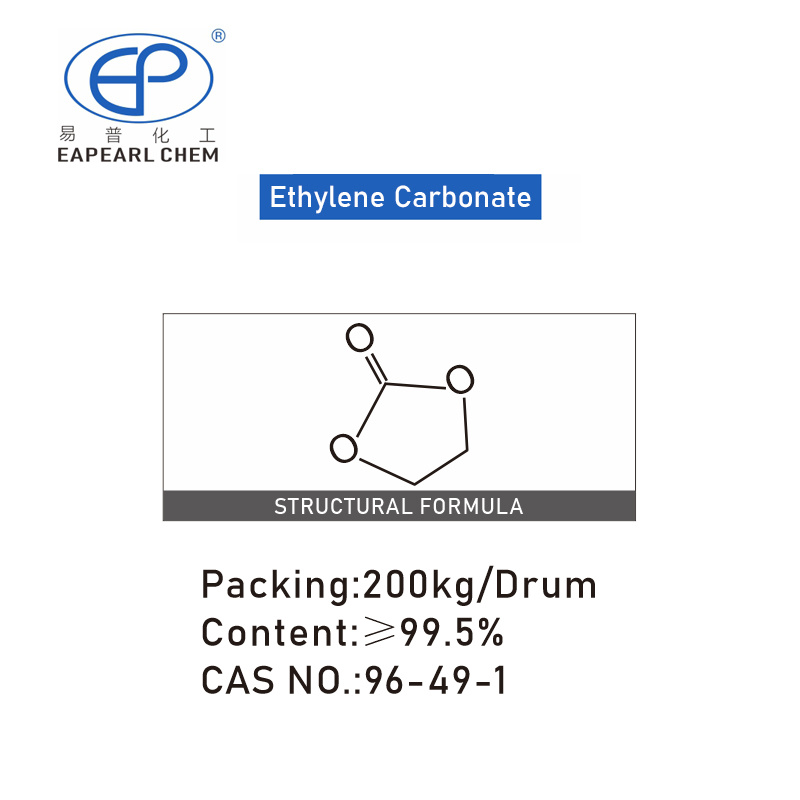

Ethylene Carbonate Packaging Information

| EC packaging | Capacity | 20GP | 40GP |

| drum | 200 kg /drum | total 80 drums, Net 16 ton | total 128 drums, Net 25.6 ton |

| IBC drum | 800 kg /IBC | total 20 IBC, Net 16 ton | total 32 IBC, Net 25.6 ton |

| ISO Tank | 18.5 ton /ISO Tank | 1 ISO Tank, Net 18.5 ton | N/A |

For ethylene carbonate, we welcome you to test and check the quality, if you need a sample please contact our sales team to discuss your sample requirements, we believe that our product quality is suitable for the specific application. We provide samples free of charge but the shipping cost will be borne by you.

Applications of Ethylene Carbonate

Ethylene carbonate is a versatile organic compound with a wide array of applications across various industries due to its unique chemical properties, such as high dielectric constant, excellent solvency, and ability to participate in chemical reactions. Here’s a detailed look at its specific applications:

Electrolyte Solvent in Lithium-Ion Batteries

Ethylene carbonate is indispensable in the electrolyte formulations of lithium-ion batteries due to its superior electrochemical stability and ability to facilitate efficient lithium ion transport. When used in electrolytes, ethylene carbonate undergoes decomposition to form a solid electrolyte interface (SEI) on the anode surface. This SEI is critical in preventing the electrolyte’s direct contact with the lithium anode, thereby enhancing the battery’s safety and performance by reducing the risk of thermal runaway and extending the battery’s life by minimizing capacity fade over cycles. The presence of ethylene carbonate in the electrolyte solution significantly improves the ionic conductivity, ensuring efficient charge and discharge cycles crucial for high-performance applications like electric vehicles and portable electronics.

Solvent for Polymer Production

In polymer production, particularly in synthesizing polycarbonates, ethylene carbonate acts as a solvent and a monomer. Its high boiling point and ability to dissolve various precursors make it an excellent medium for carrying out polymerization reactions under controlled conditions. This application is pivotal in producing high-grade plastics with applications ranging from compact discs and DVDs to lenses and other components requiring materials with high transparency, durability, and thermal resistance. The solvent properties of ethylene carbonate facilitate the production of polymers with consistent molecular weights and properties, essential for manufacturing advanced materials.

Intermediate in Chemical Synthesis

As an intermediate in chemical synthesis, ethylene carbonate is used to produce a wide range of chemical compounds, including urethanes, ureas, and various carbonate esters. Its reactivity with amines to form carbamates is leveraged in synthesizing active pharmaceutical ingredients (APIs) and agrochemicals. This versatility makes ethylene carbonate a valuable starting material in organic synthesis, enabling the development of compounds with specific functionalities required in medical, agricultural, and industrial applications. The ability to undergo reactions with nucleophiles opens pathways to synthesizing complex molecules, highlighting ethylene carbonate’s role in facilitating innovative chemical processes.

Plasticizer

As a plasticizer, ethylene carbonate is integrated into polymer matrices to enhance their flexibility and processability. This application is crucial in producing soft PVC (polyvinyl chloride) used in flexible cables, flooring, roofing membranes, and other applications where material flexibility is paramount. Ethylene carbonate’s incorporation into polymers reduces intermolecular forces, thereby improving the material’s ductility and durability. This plasticizing effect is essential for manufacturing consumer goods, packaging materials, and various industrial products requiring customized mechanical properties.

Surface Coatings

In surface coatings, ethylene carbonate’s role extends beyond merely being a solvent. It acts as a coalescing agent, enhancing the film formation process and ensuring uniformity and durability of the coating. The incorporation of ethylene carbonate in paint formulations improves the wetting properties, flow characteristics, and drying times, resulting in smooth, durable finishes with enhanced aesthetic and protective qualities. This application is particularly beneficial in automotive, architectural, and industrial coatings, where performance and longevity are critical.

Cosmetics and Personal Care Products

In the cosmetics industry, ethylene carbonate’s solubility and non-toxic nature make it an ideal solvent and performance enhancer for skincare, haircare, and fragrance products. It helps to solubilize and stabilize active ingredients, ensuring they remain effective throughout the product’s lifespan. Additionally, its use in formulations can impart a desirable texture and consistency, enhancing the user experience. The role of ethylene carbonate in personal care products underscores the importance of chemical innovation in developing safe, effective, and consumer-friendly cosmetic solutions.

Electrochemistry and Other Industrial Applications

In electrochemistry, ethylene carbonate’s high dielectric constant and stability under electrochemical conditions make it suitable for use in supercapacitors and fuel cells, where it functions as an electrolyte or a component thereof. These applications exploit its ability to support high energy density and rapid charging/discharging cycles, critical for energy storage technologies. Furthermore, its solvent properties are utilized in industrial cleaning and degreasing operations, offering an effective solution for removing stubborn residues from metal parts and electronic assemblies, highlighting its versatility and importance across various technological and industrial fields.

Ethylene carbonate is a compound of significant industrial importance, attributed to its unique chemical properties and wide range of applications. From playing a crucial role in the energy sector through its use in lithium-ion batteries to serving as a versatile solvent and intermediate in chemical synthesis, its contributions to modern technology and industrial processes are invaluable. As industries continue to evolve and seek sustainable and efficient materials, ethylene carbonate’s relevance is poised to grow, reflecting its essential role in driving innovation and environmental sustainability.

REQUEST A QUOTE FOR MORE DETAILS

Technical of Ethylene Carbonate

| Name | Ethylene carbonate |

| Synonyms | EC, Ethylencarbonat, 1,3-Dioxolan-2-one, Cyclic ethylene ester, ETHYLENE CARBONATE (EC), cyclicethylenecarbonate, 2-hydroxyethyl carbonate, Cyclic ethylene carbonate, carbonicacid,ethyleneester |

| CAS | 96-49-1 |

| EINECS | 202-510-0 |

| Molecular Formula | C3H4O3 |

| Molar Mass | 88.06 |

| Density | 1.321g/mLat 25°C(lit.) |

| Melting Point | 35-38°C(lit.) |

| Boling Point | 243-244°C740mm Hg(lit.) |

| Flash Point | 320°F |

| Water Solubility | 214 g/L (20 ºC) |

| Solubility | H2O: 1M at20°C, clear, colorless |

| Vapor Presure | 0.02 mm Hg ( 36.4 °C) |

| Vapor Density | 3.04 (vs air) |

| Appearance | Crystallization |

| Specific Gravity | 1.321 |

| Color | White to yellow |

| BRN | 106249 |

| pKa | 3.86[at 20 ℃] |

| PH | 7 (200g/l, H2O, 20℃) |

| Storage Condition | Store below +30°C. |

| Stability | Stable. Incompatible with strong oxidizing agents, acids, bases, reducing agents. |

| Sensitive | Easily absorbing moisture |

| Explosive Limit | 3.6-16.1%(V) |

| Refractive Index | 1.4199 |

| MDL | MFCD00005382 |

| Physical and Chemical Properties | Appearance white solid |

| melting point 35-37°C | |

| HS Code | 29209010 |

| Toxicity | LD50 orally in Rabbit: > 5000 mg/kg LD50 dermal Rabbit > 2000 mg/kg |

| LogP | 0.11 at 20℃ |

Ethylene Carbonate Production

The production of ethylene carbonate typically involves the reaction between ethylene oxide and carbon dioxide under specific conditions. This process, known as the carbonylation of ethylene oxide, is a well-established industrial method that yields ethylene carbonate as the primary product. Here’s a detailed description of the specific production process:

1. Raw Materials Preparation

- Ethylene Oxide: Obtained either as a direct byproduct of ethylene oxidation or through other chemical processes involving ethylene.

- Carbon Dioxide: Sourced from industrial gas suppliers or as a byproduct from other chemical processes, ensuring purity to avoid unwanted side reactions.

2. Reaction Process

- The production process begins with the introduction of ethylene oxide and carbon dioxide into a reaction vessel. The vessel is typically equipped with stirring mechanisms to ensure thorough mixing of the reactants.

- The reaction between ethylene oxide and carbon dioxide is catalyzed by a variety of catalysts. Common catalysts include quaternary ammonium or phosphonium salts, which facilitate the formation of ethylene carbonate at lower temperatures and pressures compared to uncatalyzed reactions.

- The process is typically carried out under elevated pressure (ranging from 5 to 20 MPa) and moderate temperatures (between 120°C to 180°C). These conditions are optimized based on the catalyst used and the desired reaction rate and product yield.

3. Product Recovery and Purification

- After the reaction is deemed complete, the reaction mixture is cooled, and the pressure is reduced. Ethylene carbonate, being a solid at room temperature, crystallizes out of the mixture.

- The crude ethylene carbonate is then separated from the reaction mixture, often through filtration or centrifugation, to remove any unreacted materials and catalyst residues.

- Further purification is achieved through recrystallization or distillation. Recrystallization involves dissolving the crude product in a suitable solvent at elevated temperatures, then cooling the solution to precipitate purified ethylene carbonate. Distillation, albeit less common due to ethylene carbonate’s high boiling point, can be employed under reduced pressure to obtain high-purity product.

4. Quality Control

- The final product undergoes rigorous quality control tests to ensure it meets the required purity and quality specifications. These tests typically include gas chromatography (GC), high-performance liquid chromatography (HPLC), and spectroscopic analyses to quantify purity and identify any impurities.

- The product’s physical properties, such as melting point and solubility, are also tested to confirm consistency with expected standards.

5. Packaging and Storage

- Once approved by quality control, the purified ethylene carbonate is packaged in appropriate containers, such as drums or bags, depending on the quantity and customer requirements. Packaging materials are chosen to prevent moisture ingress and product degradation.

- The packaged product is stored in a cool, dry place to maintain its stability and prolong its shelf life. Proper storage conditions are crucial to prevent product degradation, as ethylene carbonate can slowly decompose in the presence of moisture.

REQUEST A QUOTE FOR MORE DETAILS

Ethylene Carbonate: Storage and Environmental Disposal

Ethylene carbonate is an organic compound widely used across various industries due to its versatile applications, including as a solvent in lithium-ion batteries, in the synthesis of polymers, and as an intermediate in chemical manufacturing. Proper storage and disposal practices are crucial to ensure safety and minimize its environmental impact. This part provides a comprehensive overview of the best practices for storing ethylene carbonate and the environmentally responsible methods for its disposal.

Storage of Ethylene Carbonate

Ethylene carbonate is a stable compound under normal storage conditions, but certain precautions are necessary to maintain its integrity and prevent hazards.

Conditions

- Temperature: Store ethylene carbonate in a cool, well-ventilated area away from direct sunlight and sources of heat. Although ethylene carbonate is solid at room temperature, maintaining a stable, cool environment helps preserve its quality.

- Containers: Use appropriate, sealed containers made of materials compatible with ethylene carbonate, such as stainless steel or certain types of plastics, to prevent contamination and moisture ingress.

- Ventilation: Storage areas should be well-ventilated to prevent the accumulation of any vapors that may be released, especially if the compound is heated above room temperature.

- Segregation: Keep ethylene carbonate away from incompatible substances, such as strong acids or bases, and oxidizing agents, to prevent reactive incidents.

Handling Precautions

- Personal Protective Equipment (PPE): Handlers should wear appropriate PPE, including gloves, eye protection, and long-sleeved clothing, to prevent skin and eye contact.

- Spill Management: Establish spill management procedures, including the use of inert absorbent materials and proper waste containers for containment and disposal.

Environmental Disposal of Ethylene Carbonate

Ethylene carbonate should be disposed of in accordance with local, state, and federal regulations to minimize its environmental impact. Improper disposal can lead to soil and water contamination, posing risks to wildlife and human health.

Methods of Disposal

- Chemical Recycling: Whenever possible, ethylene carbonate should be recycled chemically, transforming it into useful products or intermediates for further industrial applications.

- Incineration: Controlled incineration in facilities equipped with gas scrubbers and filters can be used to minimize air emissions. This method ensures the complete breakdown of ethylene carbonate into non-hazardous gases.

- Hazardous Waste Facilities: For larger quantities or contaminated ethylene carbonate, disposal should be conducted through certified hazardous waste management facilities capable of handling chemical wastes safely and in compliance with environmental standards.

The safe storage and environmentally responsible disposal of ethylene carbonate are critical to preventing health hazards and environmental pollution. By adhering to recommended storage conditions, handling precautions, and disposal methods, industries can mitigate the risks associated with this valuable chemical compound. Continuous efforts to comply with regulatory requirements and advancements in waste management technologies are essential for sustainable industrial practices involving ethylene carbonate.

Advantages of the Chinese Ethylene Carbonate Market

The Chinese ethylene carbonate market has experienced significant growth and development over the past few years, emerging as a pivotal player in the global landscape. This growth is attributed to several strategic advantages that China holds in the production, application, and export of ethylene carbonate. This part explores the key factors contributing to the success and attractiveness of the Chinese ethylene carbonate market.

Strategic Industrial Positioning

1. Robust Manufacturing Base

China boasts one of the world’s largest chemical manufacturing sectors, with ethylene carbonate production being a notable part of it. The country’s extensive manufacturing capabilities are supported by advanced technological infrastructure, large-scale plants, and a continuous focus on innovation. This robust manufacturing base allows for the efficient, large-scale production of ethylene carbonate, meeting both domestic and international demands.

2. Supply Chain Integration

The Chinese chemical industry benefits from highly integrated supply chains, encompassing raw material suppliers, manufacturers, and distributors. This integration ensures a seamless flow of materials and products, reducing production costs and lead times. For ethylene carbonate, the availability of key raw materials such as ethylene oxide and carbon dioxide within the country further streamlines the production process.

Cost Competitiveness

3. Economies of Scale

The significant scale of production facilities in China, combined with the high volume of ethylene carbonate produced, results in economies of scale that can significantly lower production costs. These cost advantages make Chinese ethylene carbonate competitively priced in the global market, attracting a wide range of international buyers.

4. Government Support and Subsidies

The Chinese government has been supportive of the chemical industry through various policies, subsidies, and incentives aimed at promoting research, development, and environmental sustainability. Such support has facilitated the growth of the ethylene carbonate market, encouraging innovation and the adoption of green manufacturing practices.

Innovation and Research & Development (R&D)

5. Focus on Innovation

Chinese companies and research institutions are at the forefront of innovation in chemical synthesis and application development. Significant investments in R&D have led to advancements in ethylene carbonate production technologies, including more efficient catalysts and processes that minimize environmental impact.

6. Diverse Application Development

China’s ethylene carbonate producers are not just focused on manufacturing; they are also pioneering new applications and uses for the compound. From advanced battery technologies to novel polymers and green solvents, the Chinese market is expanding the utility of ethylene carbonate, driving global demand.

Global Trade Dynamics

7. Export Capabilities

With its well-established logistics and transportation infrastructure, China is a leading exporter of ethylene carbonate, capable of efficiently reaching global markets. The country’s strategic maritime and land trade routes facilitate the cost-effective distribution of ethylene carbonate to major markets in Asia, Europe, and the Americas.

8. Strategic Partnerships and Collaborations

Chinese companies actively seek and engage in international partnerships, joint ventures, and collaborations, enhancing their global reach and technological capabilities. These partnerships not only expand market access but also foster technological exchange, driving further innovation in ethylene carbonate applications.

Environmental Regulations and Sustainability

9. Adherence to Environmental Standards

In response to global environmental concerns, Chinese ethylene carbonate manufacturers are increasingly adopting sustainable and eco-friendly production methods. Stricter environmental regulations and a growing commitment to green chemistry are leading to cleaner production processes, which is crucial for maintaining competitiveness in environmentally conscious markets.

Our Team

FAQs of Ethylene Carbonate

A1: we provide ethylene carbonate primarily for its use in lithium-ion batteries as an electrolyte solvent, and in the manufacturing of polycarbonates, solvents, and as an intermediate in various chemical synthesis processes.

A2: To purchase ethylene carbonate, the following qualifications are generally necessary:

- Business License: Proof of a legitimate business operation.

- Safety Compliance Certificate: Documentation proving your facility complies with local, state, and federal safety regulations.

- Hazardous Chemical Handling License: Specific to regions where this is required, indicating that your entity is authorized to handle dangerous chemicals.

- Professional Training Records: Showing that your staff has received proper training in handling hazardous materials.

A3: Ethylene carbonate should be handled with care, following these guidelines:

- Personal Protective Equipment (PPE): Always use appropriate PPE, including gloves, goggles, and protective clothing.

- Ventilation: Ensure adequate ventilation in storage and handling areas to prevent vapor accumulation.

- Temperature-Controlled Storage: Store ethylene carbonate in a cool, dry place away from direct sunlight and sources of heat.

- Segregation: Keep it away from incompatible materials, such as strong acids or bases and oxidizing agents.

A4: Improper handling can lead to health risks such as skin and eye irritation upon contact, respiratory issues if inhaled, and potential environmental hazards. Adhering to safety guidelines and using PPE minimizes these risks.

A5: No, ethylene carbonate should not be disposed of in regular waste. It requires disposal methods compliant with hazardous waste regulations, including recycling, chemical treatment, or incineration at a certified facility.

A6: Yes, due to its classification as a hazardous material, ethylene carbonate must be transported following regulations for dangerous goods. This includes proper labeling, packaging, and carrying the necessary documentation.

A7: Absolutely. We offer 100g-200g samples, with the client only covering shipping costs.

A8: Standard lead times are approximately 2-4 weeks, varying based on order size and destination.

A9: Our standard payment terms include a 30% advance and the balance against delivery, but terms can be negotiated for long-term partnerships.

A10: Yes, we offer comprehensive after-sales support, addressing any post-purchase queries or concerns.

A11: As a supplier, in order to provide you with an accurate quote for your product, please inform us of the quantity you require, the required purity specifications, any specific packaging needs, your shipping location, and whether your application requires any customization requirements or certifications.