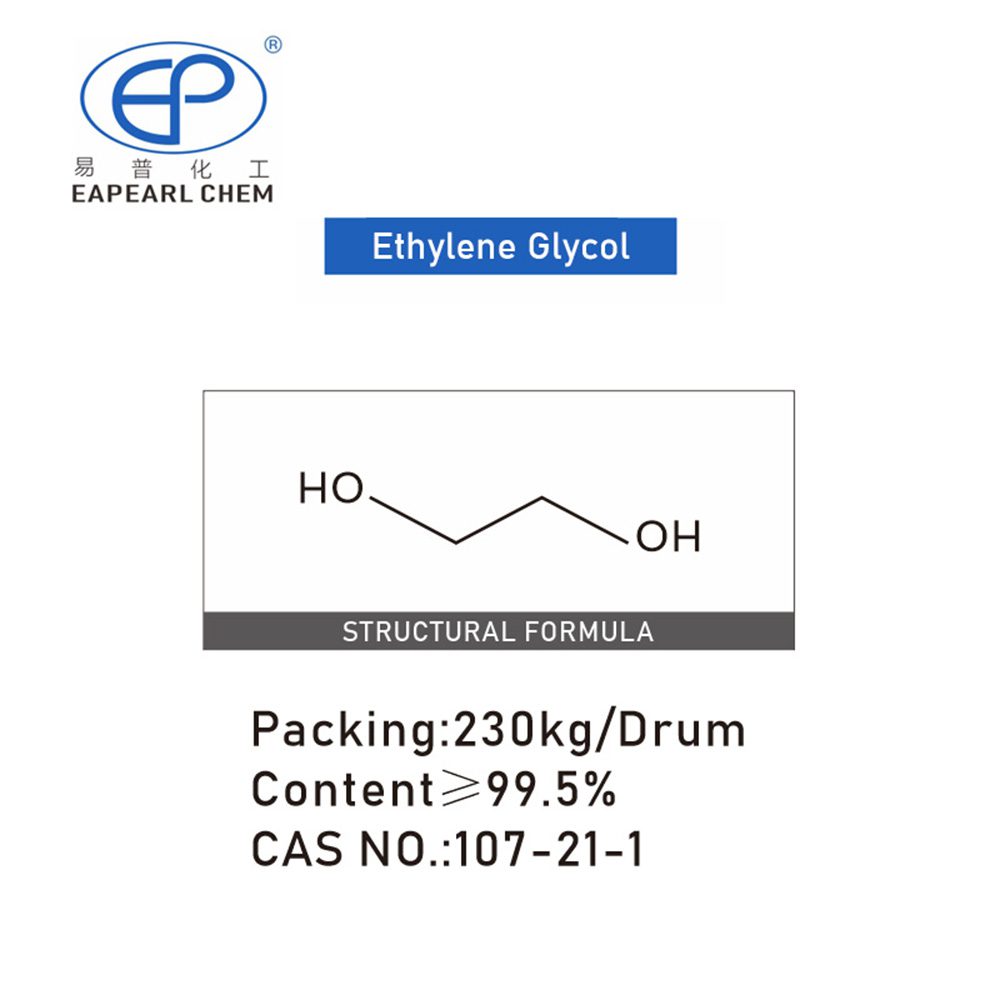

Ethylene Glycol

Unveiling the Versatility of Ethylene Glycol: From Industrial Marvel to Everyday Essential

Exploring the Applications, Benefits, and Controversies Surrounding this Widely Used Chemical Compound

Ethylene glycol is a colorless, viscous, sweet liquid that is almost odorless at room temperature. It has a high boiling point and a low freezing point. It is used as an antifreeze and in coolants, detergents, paints, lacquers, pharmaceuticals, adhesives and cosmetics. It can harm the eyes, skin, kidneys, and respiratory system. Ethylene glycol can cause death if swallowed. Workers may be harmed from exposure to ethylene glycol. The level of exposure depends upon the dose, duration, and work being done.

| Product Name | Ethylene glycol |

| Synonyms | EG, MEG, dowtherm, ethane-1, Athylenglykol, Aliphatic diol, 1,2-Ethanediol, ethane-1,2-diol, Dihydroxyethane, 2-Hydroxyethanol, Monoethylene glycol |

| CAS | 107-21-1 |

| EINECS | 203-473-3 |

| Chemical Formula | C2H6O2 |

| Molecular Weight | 62.07 |

| Purity | ≥99.9% |

For over 15 years, Eapearl has been synonymous with consistency, offering superior Ethylene Glycol that embodies quality and reliability. Recognizing the critical importance of a seamless and reliable supply chain, Eapearl has positioned itself as a trusted partner for businesses seeking efficient and uninterrupted operations.

Why Choose Eapearl?

Proven Legacy: With a legacy spanning over a decade, Eapearl understands the paramount importance of delivering consistent, high-quality Ethylene Glycol to meet the diverse needs of industries.

Comprehensive Solutions: Beyond providing a superior chemical product, partnering with Eapearl means embracing a comprehensive solution that elevates the quality and functionality of your end products. We are committed to enhancing your industrial processes.

Dedication to Excellence: Eapearl’s unwavering commitment to excellence is evident in every aspect of our operations. From stringent quality control measures to efficient logistics, we ensure that your operations benefit from the very best Ethylene Glycol available in the market.

Choose Eapearl as your trusted partner, and propel your business towards long-term industrial success with the assurance of quality, reliability, and excellence in Ethylene Glycol solutions.

Ethylene Glycol (EG) Information

| MEG packaging | Capacity | 20GP | 40GP |

| drum | 225 kg /drum | total 80 drums, Net 18 ton | total 120 drums, Net 27 ton |

| IBC drum | 1.1 ton /IBC drum | total 18 IBC drums, Net 19.8 ton | total 24 IBC drums, Net 26.4 ton |

| flexibag | 25 ton /flexibag | 1 flexibag, Net 25 ton | N/A |

| ISO Tank | 25 ton /ISO Tank | 1 ISO Tank, Net 25 ton | N/A |

For ethylene glycol, we welcome you to test and check the quality, if you need a sample please contact our sales team to discuss your sample requirements, we believe that our product quality is suitable for the specific application, we provide samples free of charge but the shipping cost will be borne by you.

Ethylene glycol production process

There are many methods for synthesizing ethylene glycol, and the ethylene oxide hydration method is generally used in industry. The production of ethylene glycol from ethylene oxide involves a process known as ethylene oxide hydration. This chemical transformation is a critical step in the synthesis of ethylene glycol, here’s a detailed description of the ethylene glycol ethylene oxide hydration process:

Feedstock Preparation:

- The process begins with the preparation of ethylene oxide (EO) as the starting material. Ethylene oxide is typically obtained through the direct oxidation of ethylene, a hydrocarbon gas derived from petrochemical sources.

Hydration Reaction:

- Ethylene oxide undergoes hydration in the presence of water to form ethylene glycol. The chemical equation for the hydration of ethylene oxide is as follows: C2H4O+H2O→HO−CH2−CH2−OH.

Catalyst:

- The hydration reaction is catalyzed by an acidic catalyst. Common catalysts include sulfuric acid or a solid acid catalyst like zeolites. The catalyst enhances the reaction rate and selectivity, facilitating the conversion of ethylene oxide to ethylene glycol.

Reaction Conditions:

- The hydration reaction is typically conducted at elevated temperatures and pressures. The specific conditions may vary, but temperatures in the range of 150 to 200 degrees Celsius and pressures ranging from 100 to 300 psi are common. These conditions promote the efficiency of the reaction.

Separation and Purification:

- After the hydration reaction, the mixture contains ethylene glycol, unreacted ethylene oxide, water, and possibly other by-products. The mixture undergoes separation processes, such as distillation or fractional distillation, to isolate and purify the desired ethylene glycol product.

Recycling and By-Product Handling:

- Unreacted ethylene oxide may be separated and recycled back into the process to improve overall efficiency and reduce waste. By-products generated during the reaction may undergo further treatment or processing.

Product Refinement:

- The isolated ethylene glycol undergoes additional refining steps to meet specific quality standards. These steps may involve additional purification processes to remove impurities and ensure the desired purity of ethylene glycol.

Storage and Distribution:

- The final ethylene glycol product is stored and distributed for various industrial applications. Ethylene glycol is widely used as an antifreeze agent, in the production of polyester fibers and resins, and in other applications where its properties are valuable.

How can we handle your order?

step 1

We will communicate with you within 24 hours after you send an enquiry.

step 2

If you need sample testing, we will send samples within 5 days,≤50kg, Express delivery recommended, usually called as DDU service; delivery time 5-7 days. Door to door service.

step 3

If you need bulk goods after the sample test is qualified, we will ship the goods to the port and keep the samples within 6 days after the order is confirmed. Sea shipping recommended, usually called as FOB, CFR, or CIF service.delivery time 10-45 days. Port to port service.

step 4

After waiting for you to receive the goods, we will arrange professional staff to pay a return visit within 7 days.

Technical of Ethylene Glycol (EG)

| Name | Ethylene glycol |

| Synonyms | EG, MEG, dowtherm, ethane-1, Athylenglykol, Aliphatic diol, 1,2-Ethanediol, ethane-1,2-diol, Dihydroxyethane, 2-Hydroxyethanol, Monoethylene glycol |

| Molecular Formula | C2H6O2 |

| Molar Mass | 62.07 |

| Density | 1.113 g/mL at 25 °C (lit.) |

| Melting Point | -13 °C (lit.) |

| Boling Point | 195-198 °C |

| Specific Rotation(α) | n20/D 1.431 (lit.) |

| Flash Point | 230°F |

| Water Solubility | miscible |

| Solubility | Miscible with water, miscible with ethanol, ether, etc. |

| Vapor Presure | 0.08 mm Hg ( 20 °C) |

| Vapor Density | 2.1 (vs air) |

| Appearance | Colorless transparent viscous liquid |

| Color | colorless |

| Odor | Odorless |

| Exposure Limit | Ceiling limit in air for vapor and mist50 ppm (~125 mg/m3) (ACGIH); TWA 10mg/m3 (particulates) (MSHA). |

| Maximum wavelength(λmax) | [‘λ: 260 nm Amax: ≤0.03’,, ‘λ: 280 nm Amax: ≤0.01’] |

| Merck | 143,798 |

| BRN | 505945 |

| pKa | 14.22(at 25℃) |

| PH | 6-7.5 (100g/l, H2O, 20℃) |

| Storage Condition | 2-8°C |

| Sensitive | Hygroscopic |

| Relative polarity | 0.79 |

| LogP | -1.36 at 25℃ |

| Explosive Limit | 3.2%(V) |

| Refractive Index | n20/D 1.431(lit.) |

| MDL | MFCD00002885 |

| Physical and Chemical Properties | Characteristics of colorless transparent viscous liquid, sweet, with hygroscopicity. |

| boiling point 198 ℃ | |

| freezing point -11.5 ℃ | |

| relative density 1.1088 | |

| refractive index 1.4318 | |

| flash point 116 ℃ | |

| solubility, lower aliphatic alcohols, glycerol, acetic acid, acetone and similar ketones, aldehydes, pyridine and similar coal tar alkali miscible, slightly soluble in ether, almost insoluble in benzene and its homologs, chlorinated hydrocarbons, petroleum ether and oils. | |

| HS Code | 29053100 |

| Toxicity | LD50 in rats, guinea pigs (g/kg): 8.54, 6.61 orally (Smyth); in mice (ml/kg): 13.79 orally (Bornmann) |

Downloadable Documents of Ethylene Glycol (EG)

REQUEST A QUOTE FOR MORE DETAILS

Ethylene Glycol (EG) Application

Ethylene glycol is a versatile chemical compound with a wide range of industrial and commercial applications. Some of the primary uses of ethylene glycol include:

Antifreeze and Coolant:

Ethylene glycol plays a crucial role in automotive antifreeze and coolant, preventing engine overheating or freezing. It is able to interfere with thehydrogen bonds in water, making it difficult for the water molecules to bind. This prevents the formation ofice crystals and in turn lowers the freezing point of water. It’s a vital component in deicing solutions for vehicles and runways, especially in winter conditions. The CDC states that minimal skin contact during antifreeze use poses no health risk. However, ethylene glycol can be toxic if ingested, leading to regulations in some states mandating the addition of a bittering agent to deter ingestion. This safety measure aims to reduce the risk of accidental poisoning.

Polyester Resins and Fibers:

Ethylene glycol is mainly used in the production of polyethylene terephthalate (PET) plastic resin. This resin is widely used to make soda, water and juice beverage containers. In addition, ethylene glycol plays a vital role in the production of polyester fibers, which are used to make clothing, upholstery, carpets and pillows. The versatility of ethylene glycol in these applications highlights its importance in a variety of everyday items, from packaging materials to textiles. Additionally, ethylene glycol is a key component in the production of fiberglass, which finds applications in items such as jet skis, bathtubs, and bowling balls.Importantly, many of these products boast energy-saving attributes, cost efficiency, and recyclability, aligning with sustainable and environmentally conscious practices.

Desiccant:

Leveraging the hygroscopic nature and high boiling point of ethylene glycol, it emerges as an excellent desiccant and dehydrating agent. Particularly well-suited for glycol dehydration, ethylene glycol plays a vital role in the natural gas industry’s dehydration systems. In this context, liquid desiccants like ethylene glycol are employed to extract water vapor from natural gas before commercial use. Natural gas extracted from underground reservoirs is typically saturated with water vapor, posing potential issues if not addressed. Glycol dehydration, utilizing various glycols, becomes essential in this process. Triethylene glycol (TEG) is a common choice for dehydrating natural gas, while ethylene glycol finds application in refrigeration units to lower hydrate temperature.

While these are the main three uses of ethylene glycol, this chemical has a variety of applications that range across many industries. Ethylene glycol is also used in:

Hydraulic Fluids: It is employed as a hydraulic fluid in various applications due to its low viscosity and excellent thermal stability.

Heat Transfer Fluids: Ethylene glycol is used as a heat transfer fluid in applications such as solar water heaters and geothermal heating systems. It helps transfer heat efficiently.

Plasticizer: In certain plastic and polymer manufacturing processes, ethylene glycol can be used as a plasticizer, improving flexibility and workability.

Solvent: It serves as a solvent in the formulation of inks, dyes, and other chemical products. Its miscibility with water and many organic solvents makes it a versatile solvent.

Brake Fluids: Ethylene glycol is used in the formulation of brake fluids due to its high boiling point and hygroscopic (water-absorbing) nature, which helps maintain the fluid’s stability under varying conditions.

Natural Gas Hydrate Inhibitor: It is employed in the oil and gas industry as an inhibitor for the formation of natural gas hydrates, which can obstruct pipelines and equipment.

Preservatives in Wood: Ethylene glycol is used as a wood preservative to prevent wood from drying out, cracking, and shrinking.

Personal Care Products: It can be found in certain personal care products such as skin creams, lotions, and hair care products due to its humectant properties, helping to retain moisture.

Lab Use: Ethylene glycol is commonly used to extract proteins in solutions. It’s also used to preserve specimens in school labs, especially during dissection.

It’s important to note that while ethylene glycol has numerous industrial applications, it should be handled with care as it is toxic to humans and animals if ingested. Proper safety precautions and handling procedures are essential when working with ethylene glycol.

REQUEST A QUOTE FOR MORE DETAILS

Basic Differences between Ethylene Glycol and Propylene Glycol

A key distinction between ethylene glycol and propylene glycol lies in their toxicity levels. Ethylene glycol is toxic, while propylene glycol is not. In applications where toxicity is not a concern, ethylene glycol is often preferred as a heat transfer fluid due to its superior performance. However, it should not be used in situations where ingestion or accidental contact with food, drinking water, or environments involving consumable product manufacturing is likely. For applications requiring low toxicity, propylene glycol is favored for its oral safety.

Beyond toxicity, the glycols differ in physical and chemical properties. Ethylene glycol excels in performance where direct human or animal contact is minimal. It offers excellent heat transfer and frost protection, with low viscosity enhancing heat transfer efficiency. While ethylene glycol outperforms propylene glycol at lower temperatures, the latter has a higher specific heat. Consequently, more ethylene glycol circulation is needed to transfer the same energy. Propylene glycol exhibits higher viscosity and pour point under similar conditions, making it less thermally efficient than ethylene glycol at lower temperatures. The choice between the two glycols depends on specific application requirements and considerations.

Harmfulness of Ethylene Glycol

Ethylene glycol is toxic to humans and causes a number of physiological problems, including death (the Disease Control Centre estimates the lethal dose between 1,400 and 1,600 mg/kg). It is absorbed through the skin (dermal route), respiratory and gastrointestinal tracts in the human body. Consequently, ethylene glycol should not be used in applications where contamination of drinking water is possible. It should also not be used in heating or cooling systems in premises such as food processing plants or other facilities where products for consumption are manufactured.

The vapour of ethylene glycol can lead to unconsciousness, and in low concentrations, it causes irritation of the nose and throat. Much more serious are the effects of ingesting ethylene glycol. Its toxicity is mainly due to the accumulation of toxic metabolites. Ethylene glycol has a strong effect on the central nervous system (CNS). It has an acute effect similar to that of ethanol. This effect on the central nervous system prevails in the first hours after exposure. The undiagnosed or untreated intake of ethylene glycol can lead to severe bodily injury and even death.

Feedback of Ethylene Glycol

Cameroon

“Delighted with the ethylene glycol purchase for PET production. Consistent quality and timely delivery have significantly boosted our manufacturing processes in Cameroon. The product’s reliability has positively impacted our operations. We appreciate your team’s commitment to excellence and look forward to continued collaboration.”

South Africa

“We are satisfied with the ethylene glycol purchased from your company. The product meets our expectations in terms of quality and reliability. Your team’s commitment to timely delivery and customer service has been commendable. We look forward to a continued partnership for our ethylene glycol needs.”

Our Team

FAQs of Ethylene Glycol

A1: Our ethylene glycol boasts exceptional quality, with a purity level of 99.9%. Rigorous testing and adherence to strict standards guarantee its excellence, ensuring our customers receive a premium product.

A2: No, ethylene glycol and propylene glycol should not be mixed. Combining these glycols can result in unpredictable changes to their properties and compromise their effectiveness for specific applications. It is recommended to use each glycol independently to ensure optimal performance and safety.

A3: Ethylene glycol hazards include toxicity, with ingestion being highly dangerous. Skin contact may cause absorption and systemic toxicity. Inhalation of vapors can lead to respiratory irritation. Environmental impact and flammability are also concerns.

A4: Ethylene glycol can cause skin irritation if there is any exposure to the skin. Otherwise, it is not particularly dangerous. If skin is exposed to ethylene glycol, wash the skin where it was exposed with soap and water.

If ethylene glycol is exposed to the eye, it can cause inflammation and swelling of the eyelid as well as redness of the eye. If it is splashed in the eye, rinse the affected eye with cool water and seek medical attention.

A5: Absolutely. We offer 100g-200g samples, with the client only covering shipping costs.

A6: Standard lead times are approximately 2-4 weeks, varying based on order size and destination.

A7: Our standard payment terms include a 30% advance and the balance against delivery, but terms can be negotiated for long-term partnerships.

A8: Yes, we offer comprehensive after-sales support, addressing any post-purchase queries or concerns.

A9: As a supplier, in order to provide you with an accurate quote for your product, please inform us of the quantity you require, the required purity specifications, any specific packaging needs, your shipping location, and whether your application requires any customization requirements or certifications.