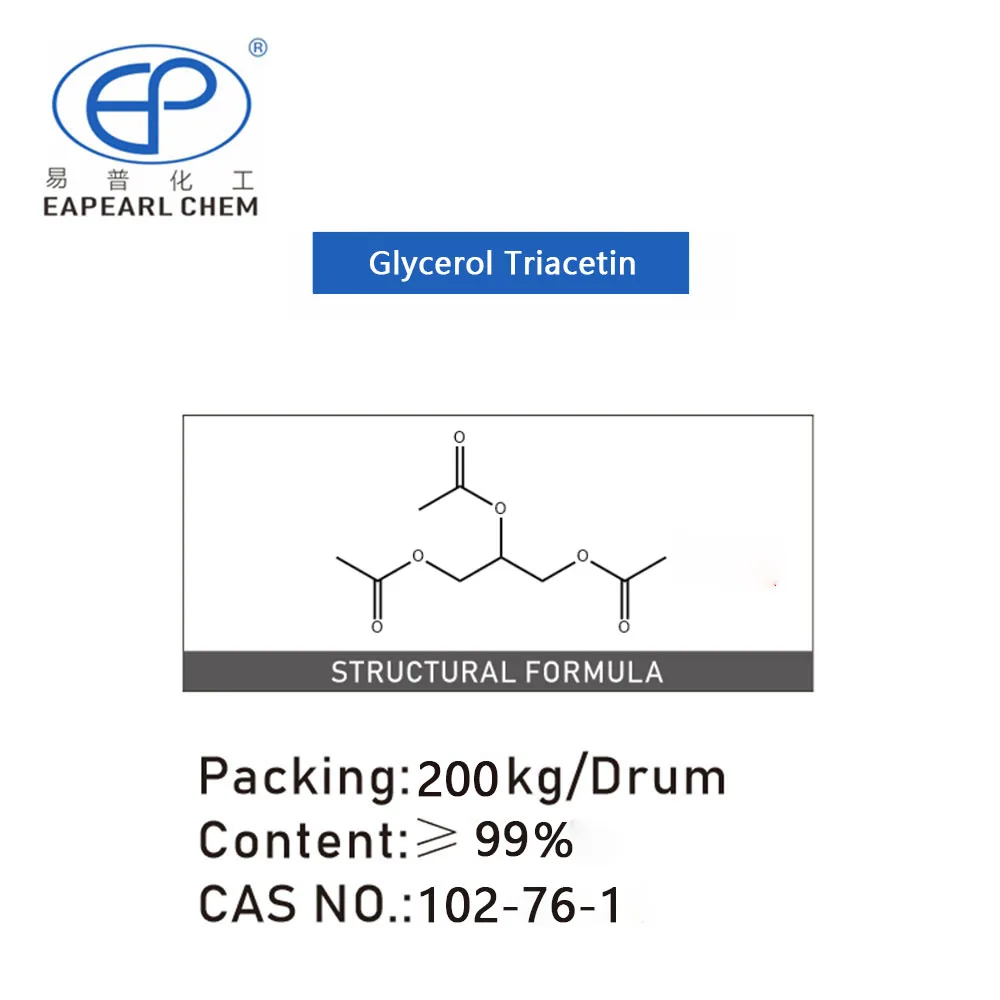

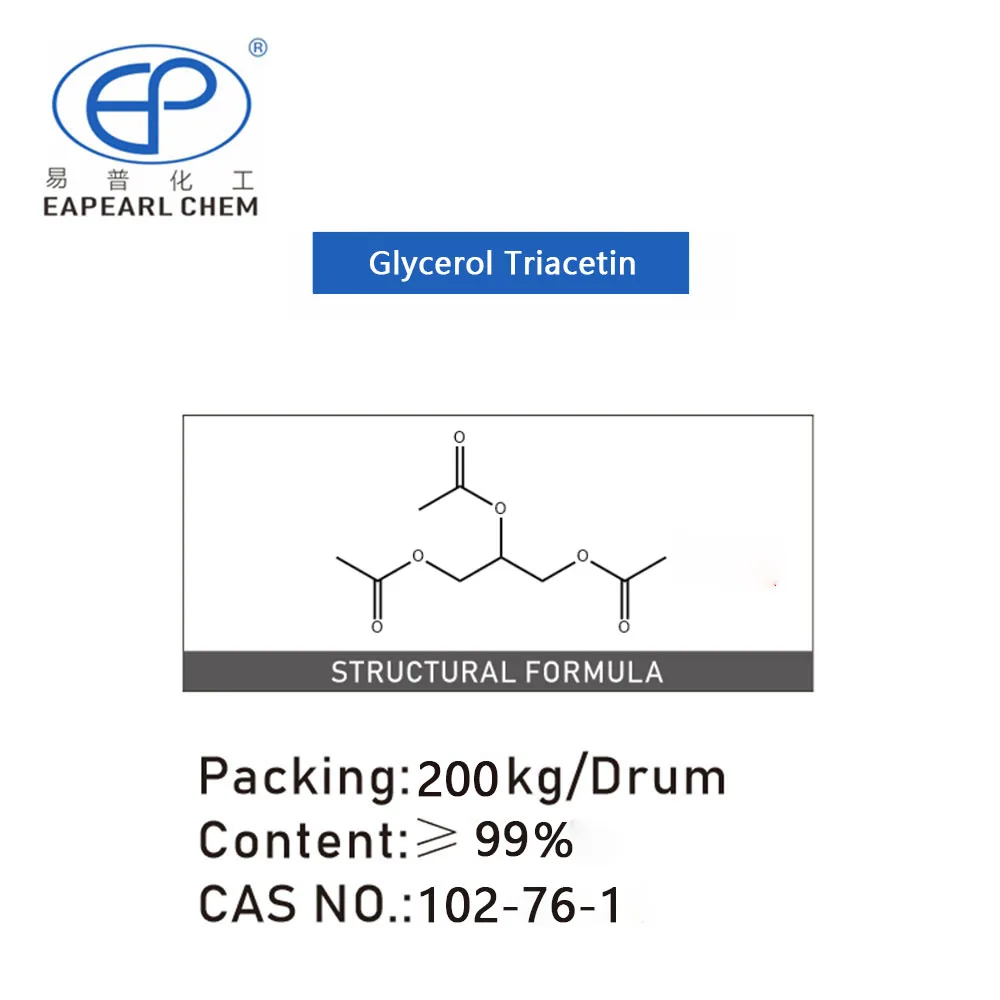

Glycerol Triacetate (GTA)

| Product Name | glycerol triacetate, triacetin |

| CAS | 102-76-1 |

| EINECS | 203-051-9 |

| Chemical Formula | C9H14O6 |

| Molecular Weight | 218.2 |

| Purity | ≥99% |

| Grade | industrial grade |

Triacetin, also known as glycerol triacetate, triacetyl glycerin, 1,2,3-propanetriol triacetate, short for GTA, is a colorless oily liquid with a slight oily odor that can cure at low temperatures. Triacetin is a safe, human-friendly non-toxic solvent certified by the US Food and Drug Administration and easy to biodegrade. As a non-toxic plasticizer, triacetin has been widely used in food, food packaging and care products, cosmetics, tobacco and other industries. It is one of the substitutes for toxic plasticizers such as DOP(dioctyl phthalate) and has been paid more and more attention in the field of plastic additives.

At Eapearl, our commitment to excellence is evident in our high-quality triacetin. We guarantee superior raw materials, ensuring swift delivery within seven days. Our solutions, fortified by advanced technology and rigorous quality control, optimize industrial processes and elevate product quality. With 15 years of expertise, we prioritize efficient collaboration to enhance our partners’ bottom line, ensuring long-term success. Eapearl’s dedication to quality, efficiency, and customer satisfaction positions us as your reliable and valuable industry partner.

Glycerol Triacetate (GTA) Packaging Information

| triacetin(GTA) packaging | capacity | 20GP | 40GP |

| drum | 200 kg /drum | total 80 drums, Net 16 ton | total 128 drums, Net 25.6 ton |

| IBC | 1 ton /IBC | total 20 IBC, Net 20 ton | total 26 IBC, Net 26 ton |

| flexibag | 24 ton /flexibag | 1 flexibag, Net 24 ton | N/A |

| ISO Tank | 24 ton /ISO Tank | 1 ISO Tank, Net 24 ton | N/A |

For triacetin, we welcome you to test and check the quality, if you need a sample please contact our sales team to discuss your sample requirements, we believe that our product quality is suitable for the specific application. We provide samples free of charge but the shipping cost will be borne by you.

Preparation Method of Glycerol Triacetate (GTA)

Triacetin is typically synthesized through the esterification of glycerol with acetic acid. This process involves reacting glycerol with acetic acid in the presence of an acid catalyst. Here’s a simplified outline of the preparation method:

Reactants Preparation: Glycerol is mixed with acetic acid. The ratio of acetic acid to glycerol is often higher than 1:1 to drive the reaction towards the formation of triacetin.

Catalyst Addition: An acid catalyst, such as sulfuric acid, is added to the mixture. The catalyst speeds up the esterification reaction between glycerol and acetic acid.

Heating and Reaction: The mixture is heated, typically under reflux, to facilitate the reaction. The heating is maintained for several hours to ensure complete conversion of glycerol to triacetin. The reaction involves the sequential acetylation of the three hydroxyl groups of glycerol.

Removal of Excess Acetic Acid: After the reaction is complete, any excess acetic acid is removed. This can be done through evaporation or distillation.

Purification: The crude triacetin is purified to remove any unreacted glycerol, acetic acid, and other impurities. Distillation is commonly used for purification.

Quality Control: The final product is tested to ensure it meets required specifications, particularly purity and concentration.

This method results in the formation of triacetin along with diacetin and monoacetin as by-products. The proportions of these can vary based on reaction conditions and the ratio of reactants. The process can be adjusted to favor the production of triacetin specifically.

How can we handle your order?

step 1

We will communicate with you within 24 hours after you send an enquiry.

step 2

If you need sample testing, we will send samples within 5 days,≤50kg, Express delivery recommended, usually called as DDU service; delivery time 5-7 days. Door to door service.

step 3

If you need bulk goods after the sample test is qualified, we will ship the goods to the port and keep the samples within 6 days after the order is confirmed. Sea shipping recommended, usually called as FOB, CFR, or CIF service.delivery time 10-45 days. Port to port service.

step 4

After waiting for you to receive the goods, we will arrange professional staff to pay a return visit within 7 days.

Technical of Glycerol Triacetate (GTA)

| Name | Triacetin |

| CAS | 102-76-1 |

| EINECS | 203-051-9 |

| Molecular Formula | C9H14O6 |

| Molar Mass | 218.2 |

| Density | 1.16g/mLat 25°C(lit.) |

| Melting Point | 3°C |

| Boling Point | 258-260°C(lit.) |

| Flash Point | 300°F |

| JECFA Number | 920 |

| Water Solubility | 64.0 g/L (20 ºC) |

| Solubility | Soluble in water, alcohol, benzene, chloroform, ether and other organic solvents, slightly soluble in carbon disulfide |

| Vapor Presure | 0.00248 mm Hg @ 250C |

| Vapor Density | 7.52 (vs air) |

| Appearance | Transparent liquid |

| Color | Clear colorless |

| Odor | Characteristic odour |

| Merck | 149,589 |

| BRN | 1792353 |

| Storage Condition | Sealed in dry,Room Temperature |

| Stability | Stable. Incompatible with strong oxidizing agents. Combustible. |

| Sensitive | Easily absorbing moisture |

| Explosive Limit | 1.05%, 189°F |

| Refractive Index | n25/D 1.429-1.431(li |

| LogP | 0.25 |

| Toxicity | LD50 i.v. in mice: 1600 ±81 mg/kg (Wretlind) |

| HS Code | 29153930 |

| Acid Number | ≤0.01 |

| MDL | MFCD00008716 |

| Physical and Chemical Properties | Density 1.155 melting point 3°C boiling point 258°C refractive index 1.429-1.433 flash point 148°C water-soluble 64.0g/L (20°C) |

Application of Glycerol Triacetate (GTA)

Triacetin has a wide range of uses, the biggest use is as a plasticizer for cigarette filters. As a wide range of chemical products, can be used for acetate fiber, nitrate fiber and other plasticizers and solvents, natural rubber and synthetic rubber also have plasticizing effect, and does not affect the vulcanization operation.

As an important chemical raw material, triacetin has been widely used in food, medicine, cosmetics, industry and other fields.

Food industry

Increase the viscosity and taste of food: triacetin is a colorless transparent liquid, which can increase the viscosity of food when added to food, and make food taste smoother.

Increase the stability of food: triacetin is a stable compound, which can improve the stability of food and extend the shelf life of food after being added to food.

Enhance the stability of spices: triacetin can be used as a stabilizer of spices, which can extend the freshness life of spices and stabilize the flavor.

As a thickener: triacetin can be used as a thickener to increase the consistency and viscosity of food, making it easier to process and package.

As an emulsifier: triacetin has good emulsifying performance, which can make the slurry and oil fully mixed and play an emulsifying effect.

Pharmaceutical industry

As a drug sustained release agent: triacetin can be used as a drug sustained release agent, by regulating the release rate of drugs, extend the duration of drug action, improve the efficacy of drugs.

As a solvent: triacetin can be used as a solvent to help the drug dissolve and facilitate oral or injectable administration.

As a component of capsules: triacetin has good capsule preparation properties and can be used as a component of capsules, which is helpful for encapsulation and storage of drugs.

Cosmetics industry

Thickener: triacetin can increase the viscosity of cosmetics, making them easier to use and apply.

Humectant: triacetin has good moisturizing properties, can absorb moisture and lock water, keep the skin moist and soft.

Lubricants: triacetin provide lubrication, making cosmetics easier to apply and push on the skin, enhancing the application experience.

Enhanced stability: triacetin can increase the stability of cosmetics and prevent their delamination or deterioration.

Industrial

Plasticizer: triacetin is widely used in the plastics industry, which can enhance the flexibility, ductility and toughness of plastics, and improve the processing performance of plastics.

Lubricant:triacetin can reduce the friction coefficient of the material, reduce friction failure, and improve the lubrication performance of the material.

Additives: triacetin can be used as chemical reaction additives, participate in the reaction, and promote the reaction.

Solvent: because of its good solubility and lubricity, triacetin can be used as a solvent for coatings, paints and cleaners.

As a gasoline additive, triacetin can reduce the amount of lead in the air. In printing and dyeing industry, triacetin can be used as a bulking agent and stabilizer of cellulose acetate. Triacetin is used as a plasticizer in ink, cellulose, film and some alkaline solvents, and is also used as a plasticizer for synthetic plastic films. Triacetin can also be used as a fixed liquid for meteorological chromatography (maximum service temperature 85 degrees Celsius, solvent is methanol, chloroform), to separate and analyze gases and aldehydes.

In conclusion, the multifaceted applications of triacetin, spanning food, medicine, cosmetics, industry, position it as a versatile and sought-after compound. As people prioritize health, environmental consciousness, and sustainable practices, the market demand for triacetin is poised for sustained growth.

If you have specific inquiries or would like to explore potential collaborations, please feel free to reach out. We are here to support your needs in the chemical raw material industry.

REQUEST A QUOTE FOR MORE DETAILS

Development Prospect of Glycerol Triacetate (GTA)

In recent years, with the increasing demand for the quality of life and the continuous progress of medical technology, triacetin, as a chemical raw material with important functions, has been widely used in food, medicine, cosmetics and other fields. According to the market research report, the global triacetin market size grew from $490 million in 2014 to $650 million in 2018, and is expected to maintain a steady growth trend in the next few years.

At present, phthalate plasticizers dominated by toxic dioctyl phthalate (DOP) and dibutyl phthalate (DBP) occupy a dominant position in industrial applications, accounting for about 80% of the total plasticizer production. Now the production and consumption of plasticizers is very large, and the use is very wide, and the annual consumption is more than 2 million tons. These substances return to the natural environment causing varying degrees of pollution and harm. DOP has a potential carcinogenic risk, developed countries and regions in the world have taken corresponding measures to limit the scope of use of DOP, phase out DOP and other plasticizers and find suitable alternative products. In acute oral, long-term contact and injection experiments, triacetin showed no toxicity to human body, and the plasticizing effect was good, and it could replace DOP and other phthalic plasticizers.

Due to the accelerated elimination of toxic plasticizers and the development and promotion of new non-toxic plasticizers has become an inevitable trend. As a green, degradable and non-toxic plasticizer, triacetin can be widely used in PVC materials, PLA polyester materials, cellulose acetate, and PVAc materials, with good plasticizing effect, and can replace DOP and other phthalic plasticizers, and can achieve similar plasticizing effects of phthalic plasticizers. Therefore, the application prospect of triacetin as a plasticizer is wide and should be promoted vigorously.

Why Us

As a supplier of triacetin, we are proud to highlight several compelling reasons for our product advantages:

- Quality and Purity: Our triacetate reaches 99% purity, ensuring high efficiency and consistency in your application. Each batch of our triacetate is subjected to rigorous quality testing to ensure that it meets industry specifications.

- Competitive Pricing: We ensure competitive pricing for our triacetin, delivering exceptional value for your investment. Trust us for cost-effective solutions without compromising on the high quality and reliability of our products.

- Technical Support: Our team of experts is available to provide technical support and guidance, ensuring that our clients can maximize the benefits of our triacetin in their specific applications.

- Consistent Supply: We understand the importance of having a dependable solvent supplier. Our robust supply chain management ensures consistent product availability, helping you maintain uninterrupted operations.

- Long-Term Partnership Approach: We value long-term relationships, offering consistent product quality and reliability for enduring partnerships.

Our commitment to transparency, quality, and flexibility in meeting your specific needs positions us as the preferred supplier in the Triacetin market. If you have specific inquiries, require documentation, or wish to explore samples and small purchases, please feel free to contact us. We are ready to provide the precise solutions you need for your business.

Our Team

FAQs of Glycerol Triacetate (GTA)

A1: As a supplier, we ensure our triacetin is of the quality with 99% purity, guaranteeing consistent performance and reliability for a wide range of industrial applications.

A2: Sure, we’re equipped to handle large-volume orders and guarantee consistent supply. Our robust production capabilities and efficient logistics network enable us to meet high demand while maintaining the quality and reliability that our customers expect.

A3: We employ rigorous batch testing and quality control processes to guarantee consistent quality in every shipment.

A4: Our minimum order quantity is 1 ton, catering to both large and small-scale needs.

A5: Absolutely. We offer 100g-200g samples, with the client only covering shipping costs.

A6: Standard lead times are approximately 2-4 weeks, varying based on order size and destination.

A7: Our standard payment terms include a 30% advance and the balance against delivery, but terms can be negotiated for long-term partnerships.

A8: Yes, we offer comprehensive after-sales support, addressing any post-purchase queries or concerns.

A9: As a supplier, in order to provide you with an accurate quote for your product, please inform us of the quantity you require, the required purity specifications, any specific packaging needs, your shipping location, and whether your application requires any customization requirements or certifications.