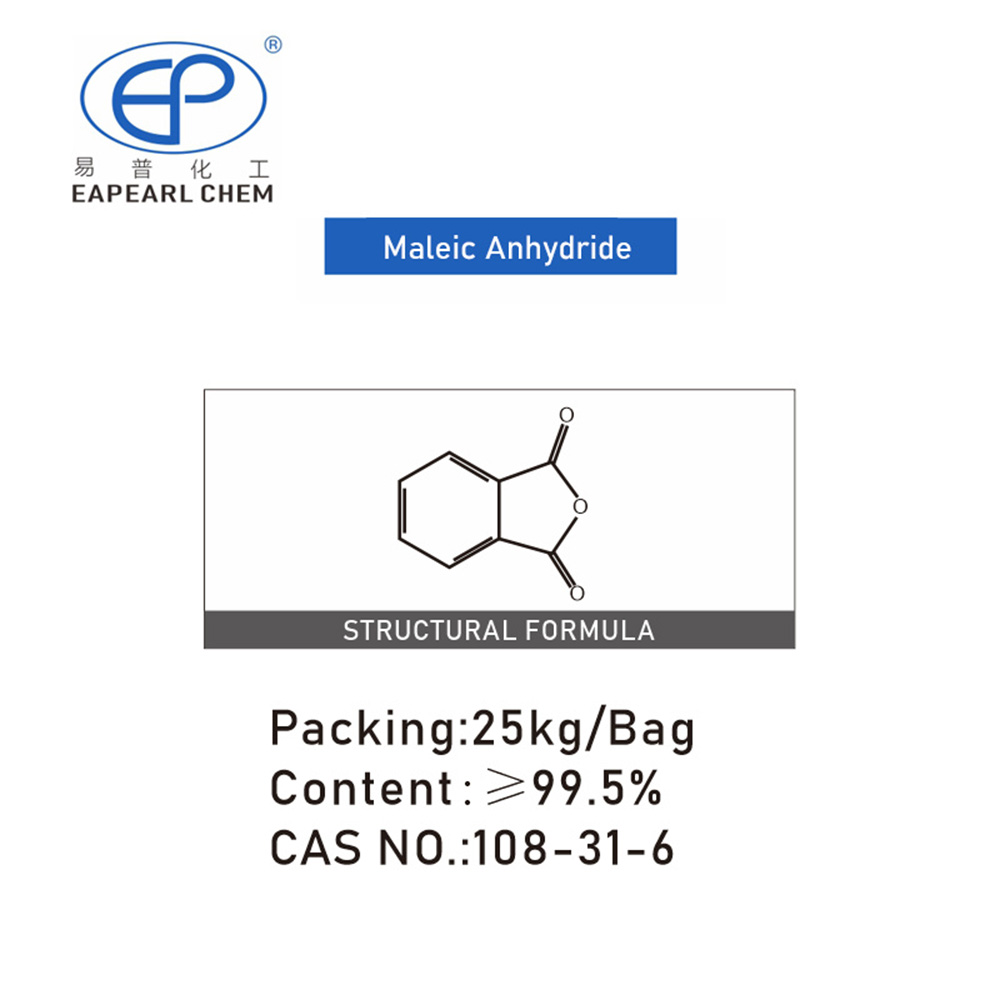

Maleic Anhydride (MA)

—— Unlock unmatched efficiency and reliability in your production processes.

Facing challenges in sourcing high-quality Maleic Anhydride?

At Eapearl, we understand your need for a reliable, pure, and compliant chemical solution. Our Maleic Anhydride, with guaranteed 99.5% purity, ensures your production is always top-notch, addressing your primary concern for quality.

Maleic Anhydride (MA) Information

Maleic Anhydride, also known as MA,2,5-FURANDIONE,2,5-Furandione, Furan-2,5-dione, MaleicAnhydride, MALIEC ANHYDRIDE, Maleic anhydride, ANHYDRIDE MALEIC, TOXILIC ANHYDRIDE, Sodium n-amyl xanthate or Cis-Butenedioic anhydrides, a colorless, crystalline organic compound. With a pungent odor, it hydrolyzes in water to form maleic acid and is highly reactive, used primarily in chemical syntheses

Packing Instruction

| MA Packaging | Capacity | 20GP | 40GP |

| Bag | 25kgs/bag | total 800 bags, Net 20 Tons | total 1040 bags, Net26 Tons |

| Ton Bag | 1 tons/bag | total 20 Ton bags, Net 20 Tons | total 24-26 Ton bags, Net 24-26 Tons |

The Application of Maleic Anhydride (MA)

Production of Unsaturated Polyester Resins (UPR): Used extensively in the manufacture of fiberglass reinforced plastics, coatings, and gel coats.

Lubricating Oil Additives: Employed as an intermediate in the synthesis of lubricant additives.

Agricultural Chemicals: Utilized in the production of pesticides and herbicides.

Pharmaceuticals: Used in the synthesis of certain pharmaceuticals and as a starting material for tetrahydrofuran (THF), which is a solvent used in pharmaceuticals.

Personal Care Products: An ingredient in the production of hair sprays, adhesives, and floor polishes.

Food Industry: Employed in the production of food additives, flavors, and artificial sweeteners.

Coatings and Inks: Used in the production of alkyd resins, which are then used in paints, inks, and coatings.

Plasticizers: Acts as an intermediate in the production of certain plasticizers.

Dyestuffs and Pigments: Involved in the manufacture of dyes, pigments, and ink components.

Paper Sizing and Coating: Used in paper treatment to improve water resistance and other properties.

Building Materials: Involved in the production of construction materials, such as floor tiles and roofing materials.

Electronics: Employed in the manufacture of materials used in the electronics industry, including insulating varnishes and wire enamels.

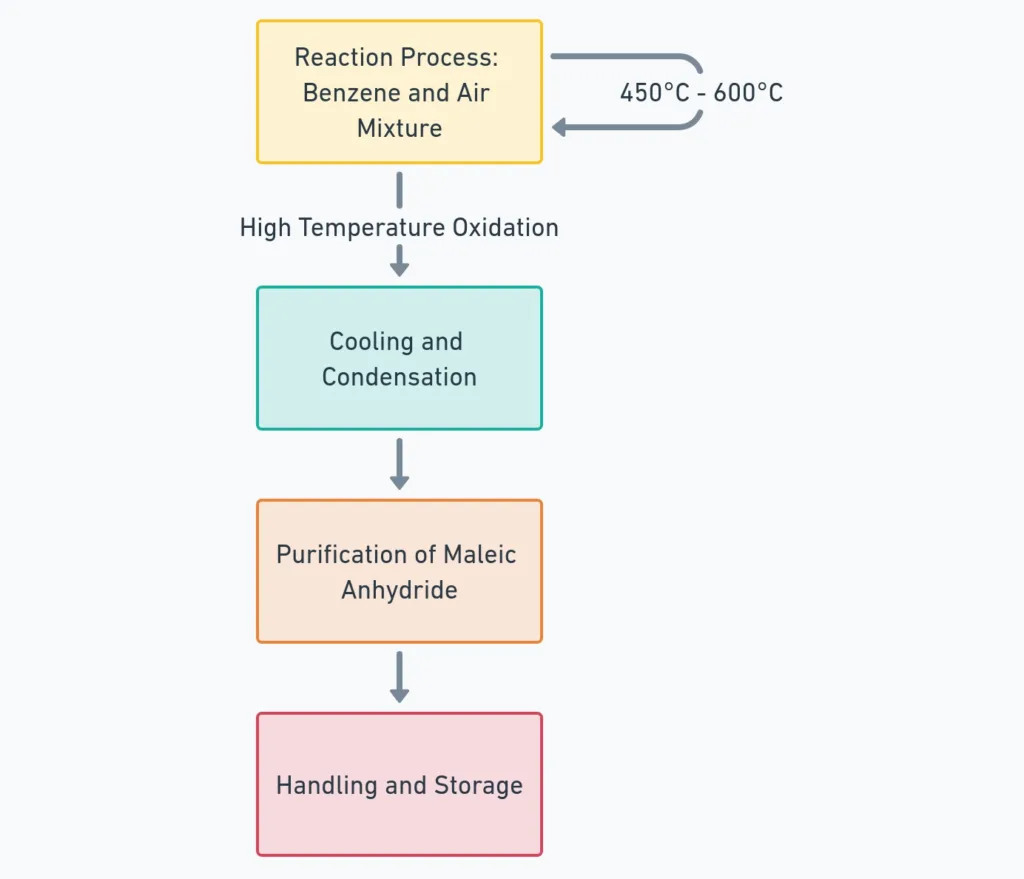

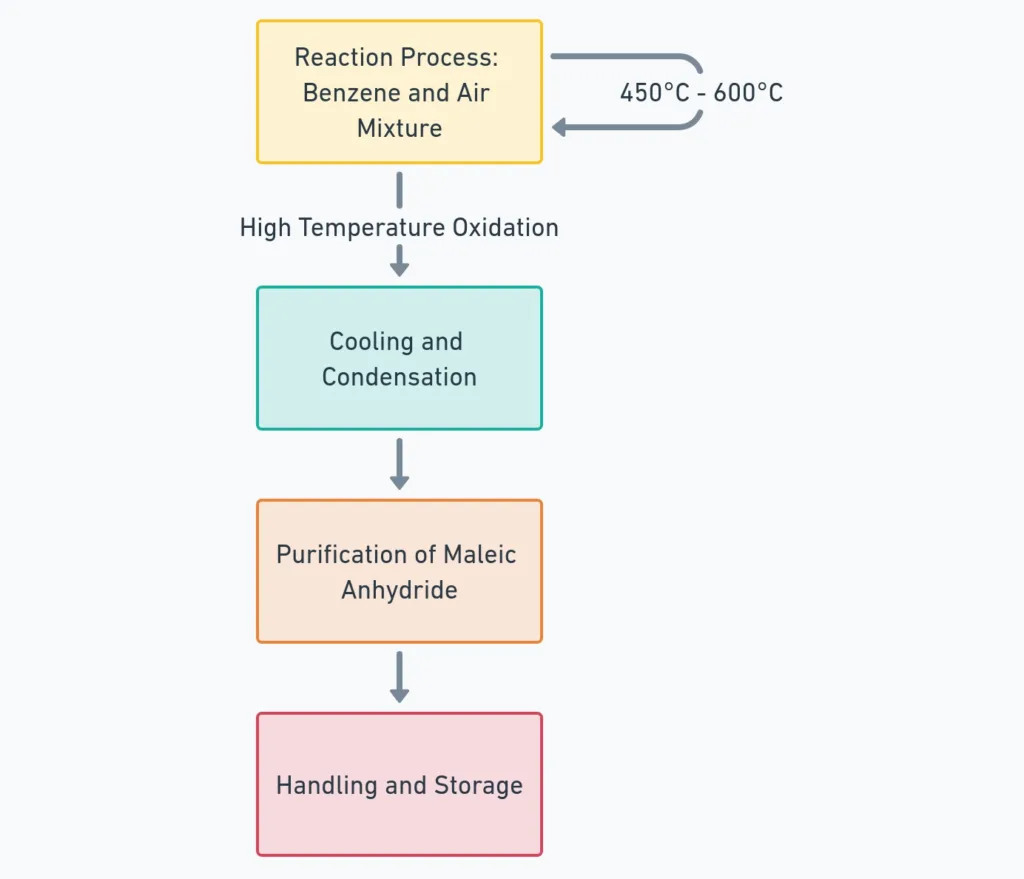

Production Technology of Maleic Anhydride (MA)

| Production Process | Description | Advantages | Disadvantages |

| Oxidation of Benzene | 1.This is the traditional method for producing Maleic Anhydride. 2.The process involves the oxidation of benzene in the presence of a catalyst, typically vanadium pentoxide (V2O5). 3.The reaction occurs at high temperatures, around 450°C to 600°C. 4.The benzene is mixed with air and passed over the catalyst, resulting in the formation of Maleic Anhydride, along with carbon dioxide and water as byproducts. | 1.Established Technology: This method is well-established and has been used for a longer period, making it a familiar process in the chemical industry. 2.High Purity: The benzene oxidation process typically yields Maleic Anhydride with high purity. | 1.Environmental and Health Concerns: Benzene is a known carcinogen, making its handling and use a significant health and environmental concern. 2.Lower Efficiency: Compared to n-butane oxidation, this process is generally less efficient in terms of yield. 3.Higher Energy Consumption: The process requires higher temperatures, leading to increased energy consumption. |

| Oxidation of n-Butane | 1.This is a more modern and increasingly preferred method for Maleic Anhydride production. 2.In this process, n-butane is used as the feedstock instead of benzene. 3.The oxidation reaction is catalyzed by a mixture of vanadium and phosphorus oxides. 4.The reaction temperature is typically lower than that in the benzene oxidation process, ranging from 350°C to 400°C. 5.This method is considered more efficient and environmentally friendly compared to the oxidation of benzene. It also results in a higher yield of Maleic Anhydride. | 1.Environmental Friendliness: n-Butane is less toxic and poses fewer environmental and health risks compared to benzene. 2.Higher Yield and Efficiency: This method typically has a higher yield and is more efficient, making it more cost-effective in the long run. 3.Lower Operating Temperatures: The process operates at lower temperatures than benzene oxidation, reducing energy consumption. | 1.Catalyst Sensitivity: The catalysts used in n-butane oxidation can be more sensitive to impurities and operational conditions, requiring precise control. 2.Dependency on Natural Gas: Since n-butane is derived from natural gas, this process is dependent on the availability and price of natural gas, which can be volatile. |

How can we handle your order?

step 1

We will communicate with you within 24 hours after you send an enquiry.

step 2

If you need sample testing, we will send samples within 5 days,≤50kg, Express delivery recommended, usually called as DDU service; delivery time 5-7 days. Door to door service.

step 3

If you need bulk goods after the sample test is qualified, we will ship the goods to the port and keep the samples within 6 days after the order is confirmed. Sea shipping recommended, usually called as FOB, CFR, or CIF service.delivery time 10-45 days. Port to port service.

step 4

After waiting for you to receive the goods, we will arrange professional staff to pay a return visit within 7 days.

REQUEST A QUOTE FOR MORE DETAILS

Maleic Anhydride (MA) Technical

| Name | Maleic anhydride |

| Molecular Formula | C4H2O3 |

| Molar Mass | 98.06 |

| Density | 1.48 |

| Melting Point | 51-56 °C (lit.) |

| Boling Point | 200 °C (lit.) |

| Flash Point | 218°F |

| Water Solubility | 79 g/100 mL (25 ºC) |

| Vapor Presure | 0.16 mm Hg ( 20 °C) |

| Vapor Density | 3.4 (vs air) |

| Appearance | White powder |

| Color | White |

| Exposure Limit | NIOSH REL: TWA 1 ppm (0.25 mg/m3), IDLH 10 ppm; OSHA PEL: TWA0.25 ppm; ACGIH TLV: TWA 0.25 ppm with an intended change of 0.1 ppm. |

| Merck | 145,704 |

| BRN | 106909 |

| pKa | 0[at 20 ℃] |

| PH | 0.8 (550g/l, H2O, 20℃)Hydrolysis |

| Storage Condition | Store below +30°C. |

| Stability | Stable. Combustible. Incompatible with water, strong oxidizing agents, alkali metals, strong bases, amines, most common metals, polymerization catalysts and accelerators. |

| Sensitive | Moisture Sensitive |

| Explosive Limit | 1.4-7.1%(V) |

| Refractive Index | 1.4688 (estimate) |

| Physical and Chemical Properties | character orthorhombic crystal system colorless needle-like or plate-like crystals. |

| melting point 52.8 ℃ | |

| boiling point 202 ℃ | |

| relative density 1.480 | |

| flash point 110 ℃ | |

| soluble in water to produce maleic acid. Dissolve in ethanol and produce esters. | |

| Use | It is used as a raw material for the production of 1, 4-butanediol, γ-butyrolactone, Tetrahydrofuran, succinic acid, unsaturated polyester resin, alkyd resin, etc., and is also used for pharmaceuticals and pesticides |

Qualifications and Documents of Maleic Anhydride (MA)

Advantages of the Chinese Maleic Anhydride (MA) Market

China is a leading producer of Phthalic Anhydride, boasting extensive manufacturing facilities. This large-scale production capability ensures a reliable supply, crucial for maintaining consistency in your operations.

Thanks to economies of scale and efficient production processes, Chinese Phthalic Anhydride is competitively priced. This cost-effectiveness can significantly reduce your procurement expenses, enhancing your overall profitability.

China’s investment in advanced manufacturing technologies translates into high-quality Phthalic Anhydride. By sourcing from China, you can be assured of procuring a product that meets the highest standards of quality and efficiency.

China’s strategic geographical location and well-developed global trade networks facilitate the efficient and timely export of Phthalic Anhydride, ensuring that your supply chain remains uninterrupted.

The Chinese government offers various incentives and support to the chemical industry. These measures can provide additional benefits and security when you engage in trade partnerships within China.

The diverse industrial applications of Phthalic Anhydride within China foster a culture of continuous improvement and innovation in production methods and product quality.

China’s focus on R&D in the chemical sector ensures ongoing advancements in Phthalic Anhydride production. This commitment to innovation means access to the latest products and technologies.

As global environmental standards tighten, Chinese manufacturers are adapting with more sustainable production methods. This alignment with environmental regulations ensures that your business remains compliant with international standards.

The well-established supply chain in China guarantees a steady availability of raw materials necessary for Phthalic Anhydride production. This robustness is key to avoiding disruptions in your supply chain.

Chinese manufacturers have carved out a significant presence in the global market, known for their reliability and quality. This reputation is a testament to the consistency and trustworthiness you can expect when sourcing from China.

Why Us

For your Phthalic Anhydride needs, EAPEARL is your go-to choice. We’re based in China, which means we make high-quality products in large amounts and offer them at attractive prices. With our quick delivery and deep market knowledge, we ensure you get the best Phthalic Anhydride, suited just for your needs.

Maleic Anhydride (MA) FAQs

Our Phthalic Anhydride boasts a high purity level of 99.5%, ensuring optimal performance for your industrial applications.

Yes, detailed product specifications and safety data sheets are available for download on our website. Please click here to access the documentation.

Pricing is determined based on order quantity and current market conditions. For a precise quote, please reach out to our sales team.

Yes, we provide discounts on bulk purchases. The discount rate varies depending on the order volume.

Our minimum order quantity is 1 ton, catering to both large and small-scale needs.

We employ rigorous batch testing and quality control processes to guarantee consistent quality in every shipment.

Standard lead times are approximately 2-4 weeks, varying based on order size and destination.

Absolutely. We offer 100g-200g samples, with the client only covering shipping costs.

Our standard payment terms include a 30% advance and the balance against delivery, but terms can be negotiated for long-term partnerships.

We manage all aspects of international shipping and customs clearance, ensuring compliance with export and import regulations.

Yes, we offer comprehensive after-sales support, addressing any post-purchase queries or concerns.

We adhere to all international trade regulations. If there are specific restrictions applicable to your industry, we’ll inform you during our initial discussions.