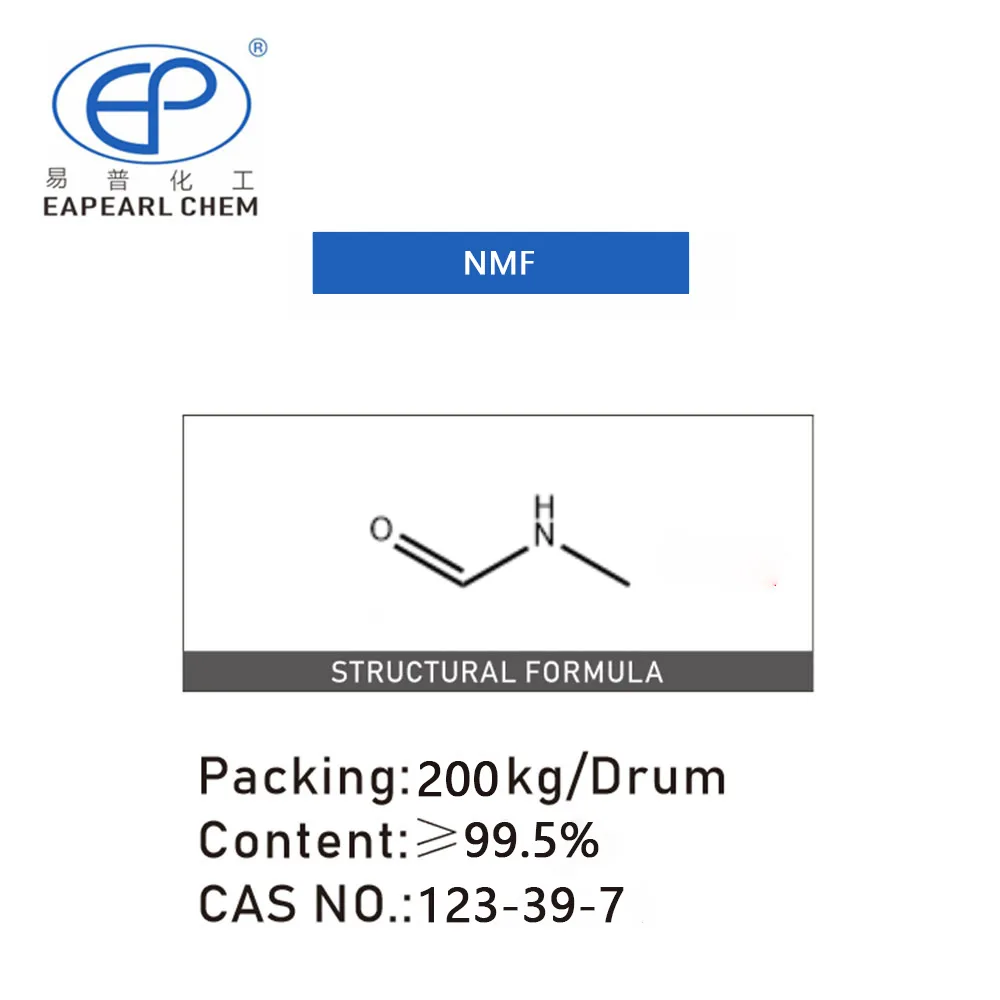

N-Methylformamide(NMF)

Discover the Pinnacle of Purity and Efficiency with Eapearl's N-Methylformamide (NMF)

----Revolutionize your industrial applications with our high-grade N-Methylformamide, tailored for excellence.

Information of N-Methylformamide(NMF)

N-methylformamide (NMF), with the chemical formula CH₃NO, is a colorless, mobile liquid widely used in the chemical industry. It has a boiling point of 180-185 °C and a melting point of -3 to -4 °C, demonstrating stability under high temperatures. NMF is notable for its excellent solubility in water and various organic solvents, making it a valuable solvent in pharmaceuticals, electronics, and other industries. It also serves as an intermediate in synthesizing diverse chemical products. Handling NMF requires safety precautions due to its irritant nature.

| Product Name: | Methyl Formamide,NMF,N-Methylformamide |

| Synonyms: | X 188 ek 7011 Methylformamide Methyl Formamide Monomethylformamide |

| CAS No.: | 123-39-7 |

| EINECS.: | 204-624-6 |

| chemical formula: | C2H5NO |

| molecular weight: | 59.07 |

| Purity | 99.5% |

| Packing: | 200kgs/drum |

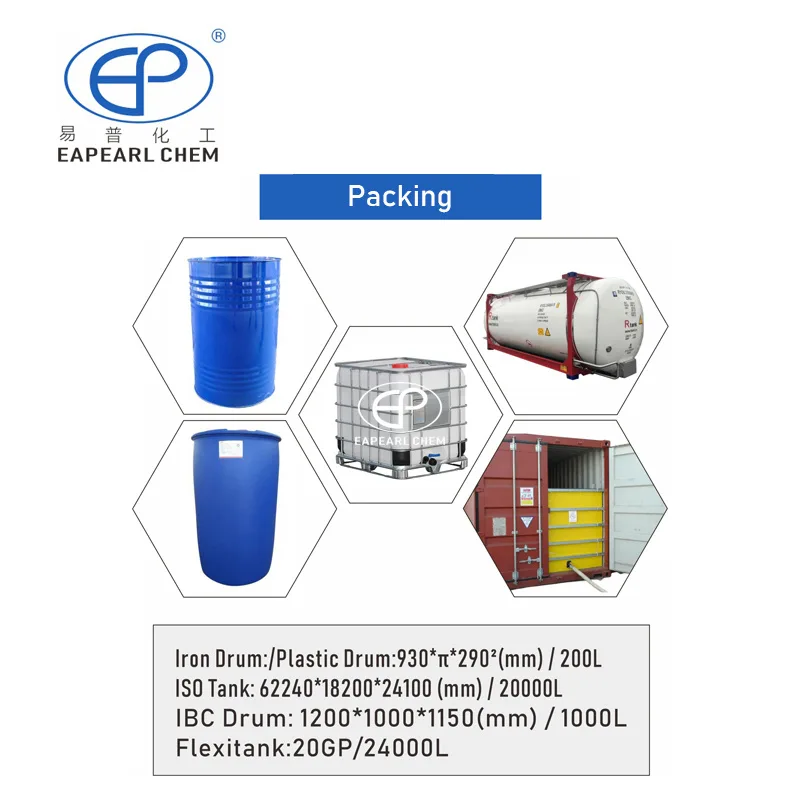

NMF Packing Instruction

| NMF Packaging | Capacity | 20GP | 40GP |

| Drum | 200kgs/drum | total 80 drums, Net 16 Tons | total 120 drums, Net24 Tons |

| IBC Drum | 1 tons/IBC drum | total 20 IBCdrums, Net 20 Tons | total 24-26 IBCdrums, Net 24-26 Tons |

| IBC Drum | 1.12 tons/IBC drum | total 20 IBCdrums, Net 22.4 Tons | total 24-26 IBCdrums, Net 26.88-29.12 Tons |

| Flexibag | 25 Tons | 1Flexibag, Net 25 Tons | N/A |

| ISOTank | 25 Tons | 1ISO Tank, Net 25 Tons | N/A |

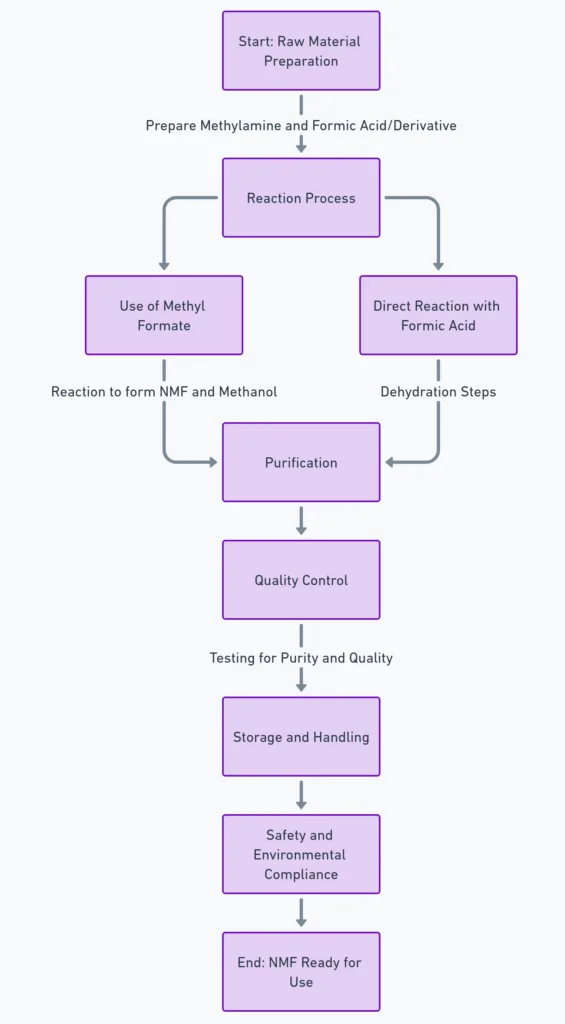

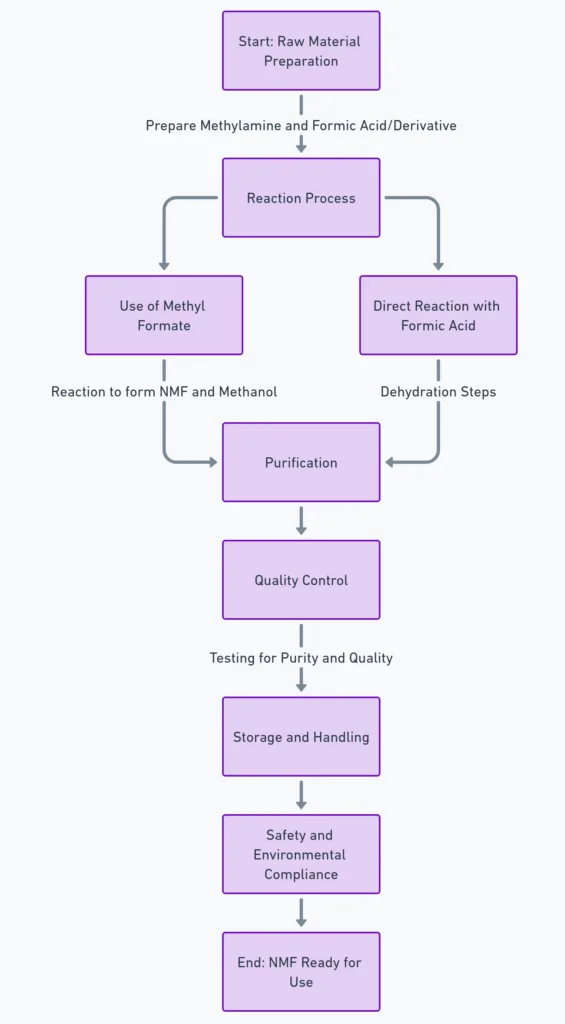

Production Technology of NMF

Raw Material Preparation:

- Methylamine and formic acid, or a formic acid derivative like methyl formate, are prepared as the primary reactants.

Reaction Process:

- The production of NMF is usually carried out through the reaction of methylamine with formic acid or methyl formate.

- If methyl formate is used, it reacts with methylamine to form NMF and methanol. The reaction can be represented as: CH3O2CH3+NH2CH3→CH3NO+CH3OH

- Alternatively, direct reaction of formic acid with methylamine can also produce NMF. This process might involve dehydration steps.

Purification:

- The reaction mixture is subjected to purification processes to isolate NMF. This can involve methods like distillation to separate NMF from other by-products and unreacted materials.

Quality Control:

- The purity and quality of the NMF produced are tested. Common tests include checking the boiling point, melting point, and purity level (often requiring over 99% purity for industrial applications).

Storage and Handling:

- Once purified and tested, NMF is stored in appropriate containers under conditions that prevent moisture absorption and degradation.

Safety and Environmental Compliance:

- Throughout the production process, safety measures are crucial due to the potentially hazardous nature of the chemicals involved. The process must also comply with environmental regulations to manage any waste or emissions.

The Application of NMF

| Industry/Application | Use of NMF | Benefits |

|---|---|---|

| Pharmaceutical Synthesis | Solvent in drug formulation | Enhances reaction rates and yields; compatible with various pharmaceutical compounds |

| Pesticide Production | Solvent in pesticide formulation | Improves solubility and stability of active ingredients; enhances effectiveness |

| Pigment and Dye Manufacturing | Solvent for pigments and dyes | Ensures uniform distribution; enhances color strength and consistency |

| Electronics Industry | Used in semiconductor and fiber production | Provides a controlled environment; essential for delicate processes |

| Textile Industry | Synthesis and processing of fibers | Improves quality and durability of textile products |

| Organic Synthesis (Intermediate) | Intermediate in chemical synthesis | Increases efficiency and selectivity in chemical reactions |

| Vitamin and Biochemical Production | Synthesis of vitamins and biochemicals | Facilitates high-purity synthesis; ensures quality of health-related compounds |

How can we handle your order?

step 1

We will communicate with you within 24 hours after you send an enquiry.

step 2

If you need sample testing, we will send samples within 5 days,≤50kg, Express delivery recommended, usually called as DDU service; delivery time 5-7 days. Door to door service.

step 3

If you need bulk goods after the sample test is qualified, we will ship the goods to the port and keep the samples within 6 days after the order is confirmed. Sea shipping recommended, usually called as FOB, CFR, or CIF service.delivery time 10-45 days. Port to port service.

step 4

After waiting for you to receive the goods, we will arrange professional staff to pay a return visit within 7 days.

REQUEST A QUOTE FOR MORE DETAILS

Technical of NMF

| Name | Methyl Formamide |

| Molecular Formula | C2H5NO |

| Molar Mass | 59.07 |

| Density | 0.872g/cm3 |

| Melting Point | -4℃ |

| Boling Point | 182.5°C at 760 mmHg |

| Flash Point | 81.5°C |

| Water Solubility | miscible |

| Vapor Presure | 0.808mmHg at 25°C |

| Physical and Chemical Properties | Melting Point:-40 |

| Boiling Point: 198 | |

| density: 1.011 | |

| water-soluble: *** = 10g/100 mL at 20 C | |

| refractive index: 1.4302 | |

| Appearance: transparent colorless liquid |

Qualifications and Documents About NMF

Market Analysis About NMF

1. Global Demand and Supply Trends

- Increasing Demand: The demand for NMF is steadily growing, driven by its expanding applications in pharmaceuticals and electronics.

- Supply Chain: Major producers are concentrated in Asia, primarily China and India, with several European and American manufacturers.

2. Key Market Players

- China: Dominates the production, supported by its large chemical manufacturing base.

- India: Emerging as a significant producer, offering competitive pricing.

- Europe and North America: Focus on high-purity NMF for specialized applications.

3. Pricing Trends

- Fluctuations: Prices vary based on purity, regional production costs, and supply chain dynamics.

- Competitive Pricing: Asian markets, especially China, offer NMF at more competitive rates due to lower production costs.

4. Regulatory Landscape

- Environmental Regulations: Stricter environmental standards in Europe and North America affect production and pricing.

- Safety Regulations: Classified as hazardous, requiring compliance with safety regulations during transportation and storage.

FAQs of NMF

NMF is primarily used as a solvent in the pharmaceutical industry for drug synthesis, in the agricultural sector for pesticides and herbicides, in the plastics and polymers industry, and in the production of semiconductors in the electronics industry.

NMF is available in various purity grades, typically ranging from technical grade (90-95% purity) to high-purity grades (up to 99.9%) for specialized applications.

The pricing of NMF varies based on purity, volume, and supplier location. Asian suppliers, particularly from China and India, tend to offer more competitive prices due to lower production costs.

Key factors include the purity of the product, the scale of the purchase, production costs, global demand and supply dynamics, and fluctuations in raw material costs.

We provide NMF in various packaging options to suit your needs, including 200L drums, IBC (Intermediate Bulk Container) ton drums, liquid bags, and tank tanks. For sea shipping, we use 20-foot containers, but 40-foot containers are also available for larger shipments. All packaging is designed to ensure safety and compliance with regulations for hazardous materials.

NMF can be stored, but it is moisture-sensitive and should be kept in a cool, dry, and well-ventilated area, away from direct sunlight. Properly stored, it can remain stable for extended periods.

The quality of NMF, particularly its purity, directly affects its performance in specific applications. High-purity NMF is essential for sensitive applications like pharmaceuticals and electronics.

Key aspects include consistent product quality, compliance with regulatory standards, competitive pricing, transparent supply chain practices, and the ability to provide stable, long-term supply.

While alternatives to NMF can vary based on the specific application, we have a dedicated team ready to provide expert advice on chemical formula substitutions. For personalized assistance in identifying suitable alternatives that meet your specific requirements, please contact us at sales@epchems.com.