N-Methyl-2-pyrrolidone(NMP)

Unleash the Potential of Top-Grade N-Methyl-2-Pyrrolidone (NMP) – Your Industrial Game-Changer!

Elevate Your Industrial Processes with Our Superior Quality NMP – Trusted by Industry Leaders Worldwide!

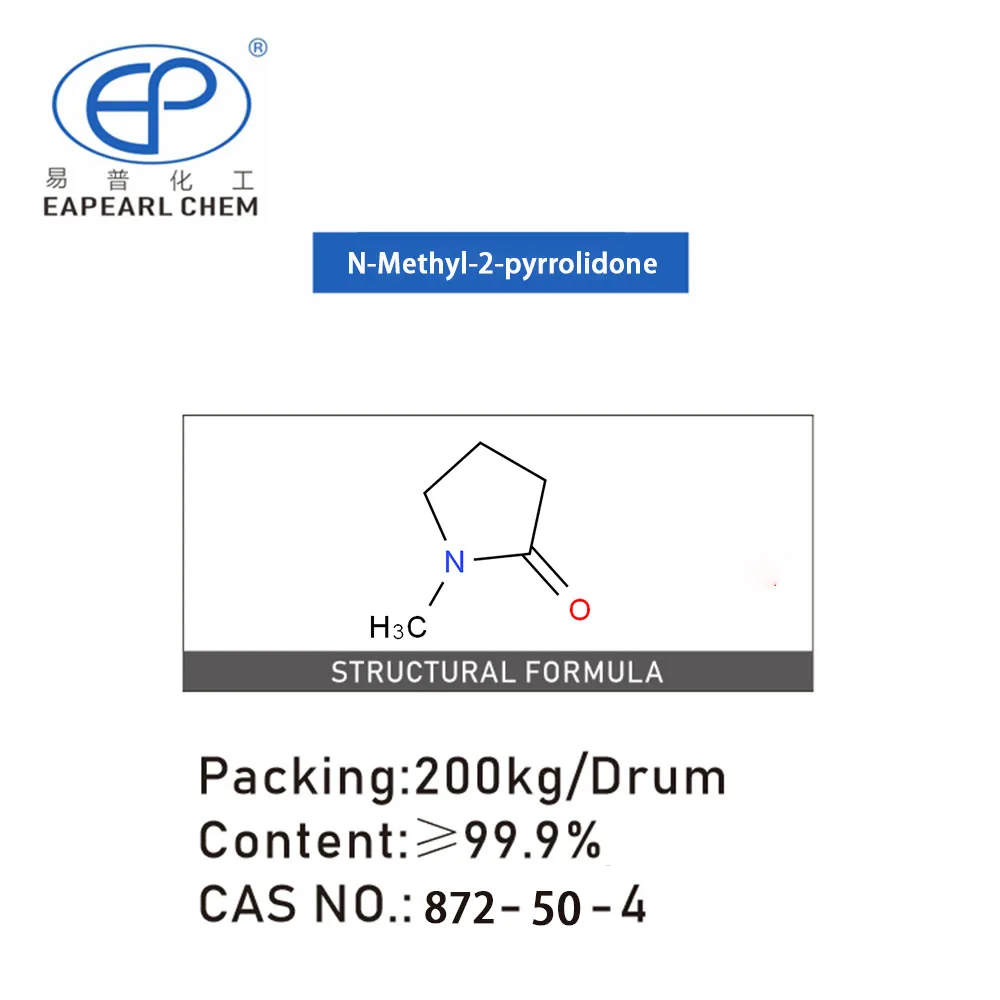

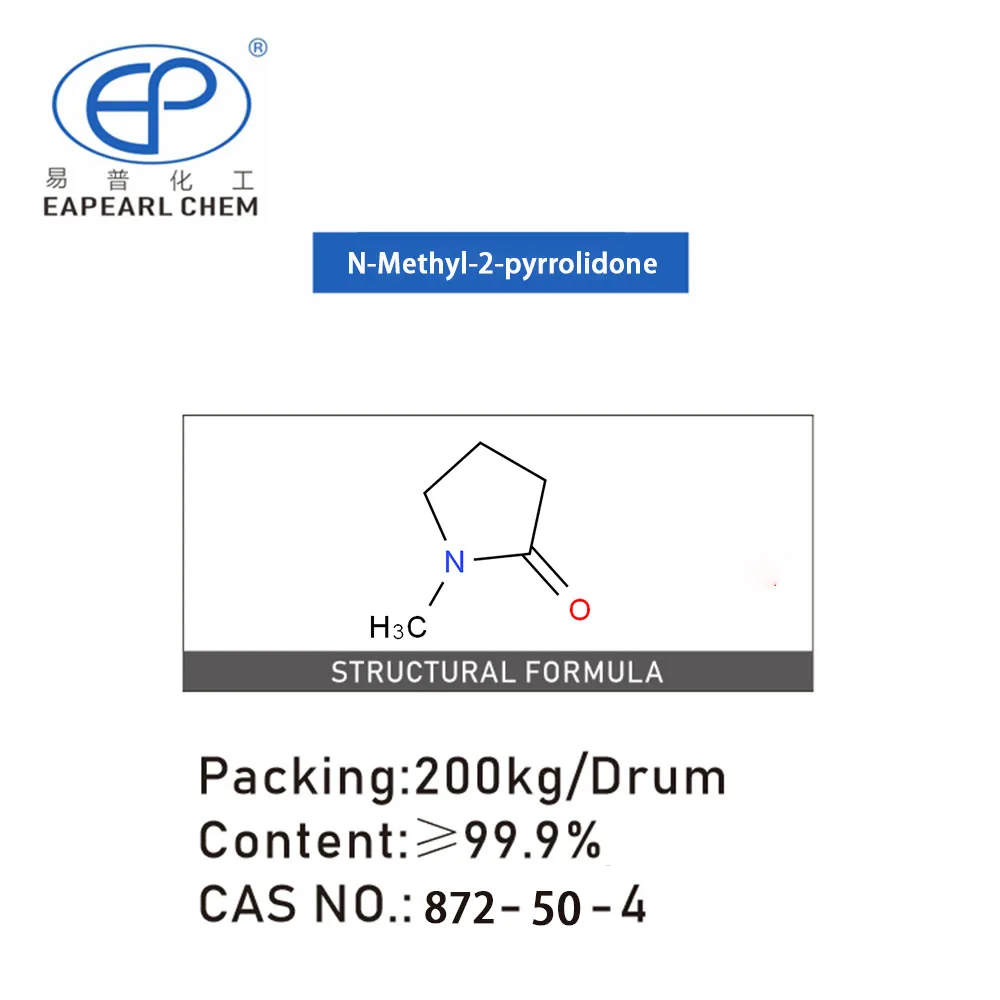

| Product Name | N-Methyl-2-pyrrolidone |

| CAS | 872-50-4 |

| EINECS | 212-828-1 |

| chemical formula | C5H9NO |

| molecular weight | 99.13 |

| Purity | ≥99.9%, ≥99% |

| Grade | battery grade, industrial grade |

N-Methyl-2-Pyrrolidone (NMP), also know as 1-Methyl-2-pyrrolidone; N-Methylpyrrolidone; N-Methylpyrrolidinone. NMP is a colorless to slightly yellow liquid that is heavier than water. NMP is a polar solvent with high boiling point, low viscosity, high chemical and thermal stability. NMP has a good solvency for a wide range of inorganic and organic compounds and it is miscible with water at all temperatures and has a high chemical and thermal stability.

The 99.9% high purity NMP is widely used in battery research and industry as a solvent for binder, slurry coating and electrode materials preparation. Other applications can be found for engineering polymers and coating resins, paint cleaning, recovery of 1,3-butadiene and acetylene and hydrogen sulfide absorption.

Eapearl’s 15-year tenure in the chemistry sector positions us as a seasoned and reliable partner for your chemical needs. With a decade and a half of experience, Eapearl has deep knowledge and understanding of chemical products and their applications. This expertise is instrumental in providing high-quality chemical solutions. We do more than just supply chemicals. Eapearl offers comprehensive solutions that enhance the quality and functionality of your final products. Our dedication to providing superior quality products is unwavering. We ensure that every product you receive from us meets the highest standards of quality and efficiency. Recognizing the importance of timely delivery, Eapearl has developed a robust and efficient logistics network. This ensures that you get the products you need, when you need them, minimizing any potential disruptions to your operations. Our goal is to not just meet immediate chemical needs but to contribute to your long-term industrial success. We achieve this by staying abreast of industry trends, continuous improvement in our product lines, and adapting to the evolving needs of our clients.

N-Methyl-2-pyrrolidone(NMP) Information

| NMP Packaging | Capacity | 20GP | 40GP |

| drum | 200 kg /drum | total 80 drums, Net 16 ton | total 128 drums, Net 25.6 ton |

| IBC | 1 ton /IBC | total 20 IBC, Net 20 ton | total 26 IBC, Net 26 ton |

| flexibag | 24 ton /flexibag | 1 flexibag, Net 24 ton | N/A |

| ISO Tank | 24 ton /ISO Tank | 1 ISO Tank, Net 24 ton | N/A |

For NMP, we welcome you to test and check the quality, if you need a sample please contact our sales team to discuss your sample requirements, we believe that our product quality is suitable for the specific application, we provide samples free of charge but the shipping cost will be borne by you.

N-Methyl-2-pyrrolidone(NMP) Synthesis Method

N-Methyl-2-pyrrolidone (NMP) is a widely used solvent and can be synthesized through several methods. One common method involves the cyclization of gamma-butyrolactone with methylamine. Here’s a simplified overview of this process:

Reactants Preparation: Gamma-butyrolactone (GBL) and methylamine are the primary reactants. Methylamine can be used in the form of an aqueous solution or anhydrous methylamine in an organic solvent.

Cyclization Reaction: The GBL and methylamine are mixed and heated to initiate the cyclization reaction. This reaction typically occurs under elevated temperature and pressure conditions. The exact conditions (temperature, pressure, and time) depend on the specific process design and the scale of the reaction.

Purification: After the reaction is complete, the mixture may contain NMP, unreacted starting materials, and other byproducts. Purification is necessary to isolate NMP. This can involve steps like distillation, solvent extraction, or crystallization, depending on the purity requirements and the nature of the impurities.

Quality Control and Analysis: The final product is analyzed to ensure that it meets the desired specifications in terms of purity and other properties. Techniques like gas chromatography (GC), high-performance liquid chromatography (HPLC), or nuclear magnetic resonance (NMR) spectroscopy can be used for analysis.

Safety considerations are crucial throughout the process, as both GBL and methylamine are hazardous chemicals. Proper handling, storage, and disposal procedures must be followed to ensure safety and environmental compliance.

How can we handle your order?

step 1

We will communicate with you within 24 hours after you send an enquiry.

step 2

If you need sample testing, we will send samples within 5 days,≤50kg, Express delivery recommended, usually called as DDU service; delivery time 5-7 days. Door to door service.

step 3

If you need bulk goods after the sample test is qualified, we will ship the goods to the port and keep the samples within 6 days after the order is confirmed. Sea shipping recommended, usually called as FOB, CFR, or CIF service.delivery time 10-45 days. Port to port service.

step 4

After waiting for you to receive the goods, we will arrange professional staff to pay a return visit within 7 days.

Technical of N-Methyl-2-pyrrolidone(NMP)

| Molecular Formula | C5H9NO |

| CAS | 872-50-4 |

| EINECS | 212-828-1 |

| Molar Mass | 99.13 |

| Density | 1.028 g/mL at 25 °C (lit.) |

| Melting Point | -24 °C (lit.) |

| Boling Point | 202 °C (lit.)81-82 °C/10 mmHg (lit.) |

| Flash Point | 187°F |

| Water Solubility | >=10 g/100 mL at 20 ºC |

| Solubility | ethanol: miscible0.1ML/mL, clear, colorless (10%, v/v) |

| Vapor Presure | 0.29 mm Hg ( 20 °C) |

| Vapor Density | 3.4 (vs air) |

| Appearance | Liquid |

| Color | ≤20(APHA) |

| Odor | Slight amine odor |

| Maximum wavelength(λmax) | [‘283nm(MeOH)(lit.)’] |

| Merck | 146,117 |

| BRN | 106420 |

| pKa | -0.41±0.20(Predicted) |

| PH | 8.5-10.0 (100g/l, H2O, 20℃) |

| PH Range | 7.7 – 8.0 |

| Storage Condition | Store at +5°C to +30°C. |

| Sensitive | Hygroscopic |

| Stability | Stable, but decomposes upon exposure to light. Combustible. Incompatible with strong oxidizing agents, strong acids, reducing agents, bases. |

| Explosive Limit | 1.3-9.5%(V) |

| Refractive Index | n20/D 1.479 |

| Physical and Chemical Properties | Characteristics of colorless transparent oily liquid, slightly amine odor. melting point -24.4 ℃ boiling point 203 ℃ relative density 1.0260 refractive index 1.486 flash point 95 ℃ , ether, Ester, ketone, halogenated hydrocarbon, aromatic hydrocarbon miscible. |

| LogP | -0.46 at 25℃ |

| Toxicity | LD50 orally in Rabbit: 3598 mg/kg LD50 dermal Rabbit 8000 mg/kg |

| Flammability | Non flammable |

| HS Code | 2933199090 |

N-Methyl-2-Pyrrolidone (NMP) Applications

N-Methyl-2-Pyrrolidone (NMP), known for its excellent solvent properties, is used in a variety of applications across multiple industries. Here are some of its key applications:

Lithium Ion Battery

NMP is utilized as a solvent during the electrode coating process in battery manufacturing. It plays a crucial role in creating a uniform and homogeneous slurry that contains various components, including the binder material (e.g., polyvinylidene fluoride or PVDF), active materials, and conductive additives. NMP is highly effective in dissolving PVDF, which is the most common binder material used to hold together the electrode materials in both anodes and cathodes of Li-ion batteries. This solubility is essential for creating a cohesive electrode structure. Due to its low reactivity, recyclability advantages and higher flashpoint, NMP is generally considered to be the solvent of choice in lithium-ion battery production. The use of NMP in the electrode coating process allows for precise control over the slurry’s viscosity, ensuring that the electrode material is evenly coated onto the metal foil substrates. This uniform coating is critical for the battery’s performance and reliability.

High Polymer Material

NMP is a necessary chemical solvent involved in chemical reaction and dilution in the manufacturing process of PPS, aramid, polyphenylene sulfide, polyimide and other polymer materials, which directly affects the smooth completion of low temperature polycondensation reaction and material product transportation.

Dissolved in polymers such as cellulose derivatives, polyamides, polyimide resins, polyesters, polystyrene, polyacrylonitrile, polyvinyl chloride, polyvinyl acetate pyrrolidone, polyurethanes, polycarbonate, polyethers and many copolymers. In many cases, NMP is mixed with other solvents, monomers, and water to create solvent formulations tailored to specific polymer applications. The choice of solvent formulation can significantly impact the efficiency of chemical reactions and the characteristics of the resulting polymer products.

Electron Industry

NMP also has important uses in the electronics industry, such as integrated circuits, hard disks and other industries requiring strict control of metal ions and particles such as deoiling, degreasing, dewaxing, polishing, rust prevention, paint removal, such as used as positive adhesive stripping liquid. NMP is also used for the cleaning of precision instruments, LCD liquid crystal materials, PCB printed circuit boards and hard disks in the IC semiconductor industry.

Surface Coating

NMP is a non-corrosive high boiler with excellent solvent properties, chemical and thermal resistance. As a result, NMP improves the performance of many surface coating systems. In particular, these effects favor the vulcanization of dry coatings at relatively high temperatures.

NMP is suitable for the production of highly filled paints because it improves rheological properties and allows the paint to improve fluidity and coverage, thus making the paint more uniform, free of holes and cracks, showing greater resistance and higher mechanical strength.

Chemical Production Agent

NMP has been widely used in large-scale recovery of hydrocarbon solvent purification. This technology takes advantage of the high solubility of hydrogen carbide in NMP, which has the following advantages over other chemical solvent extractions. No azeotrope is formed with the hydrocarbons, and NMP heating is very stable. NMP mixes easily with water in any proportion. This allows the process to be adjusted if needed and the dissolved hydrocarbons to be dissolved to form solvents. NMP has a correspondingly high boiling point at low pressure and maintains a minimal loss value during industrial-scale separation. The low viscosity at the actual representative temperature is more conducive to the exchange of substances. Examples of applications in the field of petrochemicals are as follows: NMP can be used to remove and purify acetylene from incomplete burned gases in saturated hydrocarbons.

NMP can be used as a solvent or co-solvent in the formulation of pesticides, fungicides, herbicides, seed control and therapeutic products, and is much needed in highly polar compounds. It can also be used in medicine and petrochemical and other fields.

NMP’s versatility as a solvent is due to its excellent chemical stability, high boiling point, and ability to dissolve a wide range of substances, making it a valuable ingredient in these diverse applications.

If you have specific questions or need more detailed information about any of these applications, feel free to ask. I’m here to provide the insights you need for your business considerations.

REQUEST A QUOTE FOR MORE DETAILS

NMP Industry Market Size Status and Development Trend

As the automotive industry needs to meet the growing demand for electric vehicles, the demand for NMP is increasing. The production of electric vehicles requires lithium-ion batteries. Compared with traditional batteries, lithium batteries have the advantages of small size, light weight, more charging times, and long service life, becoming the first choice for new energy vehicle power batteries. NMP is a key raw material for the production of batteries, so it is very popular. The current market forecast for NMP is 956 million and is expected to reach 1.266 billion by 2028. Based on the policy support of governments and the active promotion of automobile manufacturers, the future development of lithium batteries and related industries will face huge development opportunities, and the electric vehicle market will bring new profit growth points for lithium batteries and one of its upstream chemical solvent industry.

NMP exists not only in the automotive industry, but also in other industries such as the pharmaceutical industry. In this industry, NMP is used for the extraction, purification and crystallization of various pharmaceutical ingredients, for the development of pharmaceuticals and other ingredients NMP is also used as a cleaning agent for disinfecting metal, plastic and leather surfaces in health facilities. In recent years, an increase in the number of deaths from diseases, including COVID-19, has raised more health questions about maintaining hygiene. NMP is an effective solvent that helps facilities and individuals maintain hygiene. As a result of these growing health concerns, the demand for NMP has grown in the global market.

Why Us

As a supplier of N-Methyl-2-pyrrolidone (NMP), we would like to highlight the reasons why our product stands out and why it’s a great choice for your needs:

Premium Quality and Purity: Our NMP is of the highest quality, ensuring excellent solvency and performance for your applications. We guarantee a high level of purity, which is essential for sensitive processes, especially in industries like pharmaceuticals, electronics, and battery manufacturing.

Compliance with Regulatory Standards: We strictly adhere to all relevant health, safety, and environmental regulations. Our NMP meets and often exceeds industry standards, ensuring that you are using a product that is both safe and compliant with the latest regulations.

Consistent Supply and Reliability: We understand the importance of having a dependable supplier. Our robust supply chain and efficient logistics ensure consistent availability of our NMP, enabling you to maintain uninterrupted production schedules.

Technical Support and Customer Service: We don’t just supply a product, we offer a partnership. Our team of experts is available to provide technical support, helping you optimize the use of our NMP for your specific applications.

Environmentally Responsible Practices: We are committed to sustainable practices. Our production processes are designed to minimize environmental impact, and we offer recycling options for NMP, aiding in your sustainability efforts.

Competitive Pricing: While maintaining high quality, we offer our NMP at competitive prices, ensuring that you receive excellent value for your investment.

By choosing our NMP products, you are opting for a high-quality, reliable, and responsible solution that will support the success and efficiency of your operations.

Our Team

FAQs of N-Methyl-2-Pyrrolidone (NMP)

A1: As a supplier, we ensure our N-Methyl-2-Pyrrolidone (NMP) is of superior quality, adhering to strict purity standards for diverse industrial applications. Our NMP undergoes rigorous testing to meet both safety and regulatory compliance, guaranteeing reliability and effectiveness for our clients in sectors such as pharmaceuticals, electronics, and more. We are committed to delivering consistently high-quality NMP, ensuring customer satisfaction and trust.

A2: Sure, we’re equipped to handle large-volume orders and guarantee consistent supply. Our robust production capabilities and efficient logistics network enable us to meet high demand while maintaining the quality and reliability that our customers expect.

A3: YES, we prioritize ensuring that our N-Methyl-2-pyrrolidone (NMP) is certified as battery grade by relevant authorities. This involves strict adherence to quality standards, regulatory compliance, and ongoing quality assurance practices. We actively engage in the certification process, provide necessary documentation, and collaborate with experts to consistently meet industry standards, ensuring our NMP meets the high-quality requirements for battery applications.

A4: NMP is a highly effective solvent with several advantages, especially in industrial and chemical applications. Its key benefits include: high solvency power, stability, low volatility, compatibility, selective solvency, recyclability, electronics and battery production. These attributes make NMP a valuable solvent across various sectors, though its use necessitates careful handling due to health and environmental considerations.

A5: we manage our supply chain with strategic planning and partnerships to ensure consistent availability. We maintain robust relationships with raw material providers, invest in efficient logistics, and utilize advanced forecasting methods. This approach allows us to reliably meet customer demands while mitigating supply chain disruptions.

A6: Our minimum order quantity for NMP is 1 ton. We also offer price discounts for larger volume orders, providing a cost-effective solution for customers needing bulk quantities.

A7: The average lead time for the delivery of our products, including NMP, ranges from 7 to 40 days following order confirmation. This timeframe varies depending on your specific location and the size of your order. We strive to ensure timely and efficient delivery to meet our customers’ needs.

A8: As a supplier, in order to provide you with an accurate quote for your product, please inform us of the quantity you require, the required purity specifications, any specific packaging needs, your shipping location, and whether your application requires any customization requirements or certifications.