Polypropylene glycol

An Overview

Polypropylene Glycol (PPG) is a versatile polyether compound. This synthetic, high-molecular-weight polymer is derived from the polymerization of propylene oxide. Its unique properties and wide range of molecular weights make it suitable for diverse applications, from the production of polyurethane foams to its use as a key ingredient in personal care products.

Nature and Properties

Polypropylene Glycol is characterized by its excellent compatibility with a wide range of materials, its ability to function as a solvent, and its properties as a surfactant. It is a colorless, nearly odorless, and tasteless liquid at room temperature. Depending on its molecular weight, which can vary widely, PPG can range from a thin, watery liquid to a thick, viscous paste. This variability allows for its use in many applications, catering to the specific needs of different industries.

PPG’s low toxicity and minimal environmental impact make it a preferred choice in formulating products for human contact or consumption. Its biodegradability and non-toxic nature underscore its appeal in sectors prioritizing eco-friendly and sustainable practices.

Synonyms

PPG ; poly(oxypropylene) ; poly(propene oxide) ; Poly propylene glycol ; Poly(propylene glycol) ; POLYPROPYLENE GLYCOL 400 ; POLYPROPYLENE GLYCOL 700 ; POLYPROPYLENE GLYCOL 2000 ; POLYPROPYLENE GLYCOL 1000 ; Polypropylene glycol diol ; Polypropylene glycol 2000 ; POLYPROPYLENE GLYCOL P 400 ; Poly(propylene glycol) 4000 ; Poly(propylene glycol) 3000 ; Poly(propylene glycol) 1000 ; Polypropylene glycol – 2000 grade ; polypropylene glycol standard 5300 ; POLYPROPYLENE GLYCOL, DIOL TYPE, 700 ; POLYPROPYLENE GLYCOL, DIOL TYPE, 1000 ; POLYPROPYLENE GLYCOL, DIOL TYPE, 2,000 ; (2S)-2-{[(2R)-2-hydroxypropyl]oxy}propan-1-ol ; (2R)-2-{[(2R)-2-hydroxypropyl]oxy}propan-1-ol ; (2R)-2-{[(2S)-2-hydroxypropyl]oxy}propan-1-ol ; (2S)-2-{[(2S)-2-hydroxypropyl]oxy}propan-1-ol.

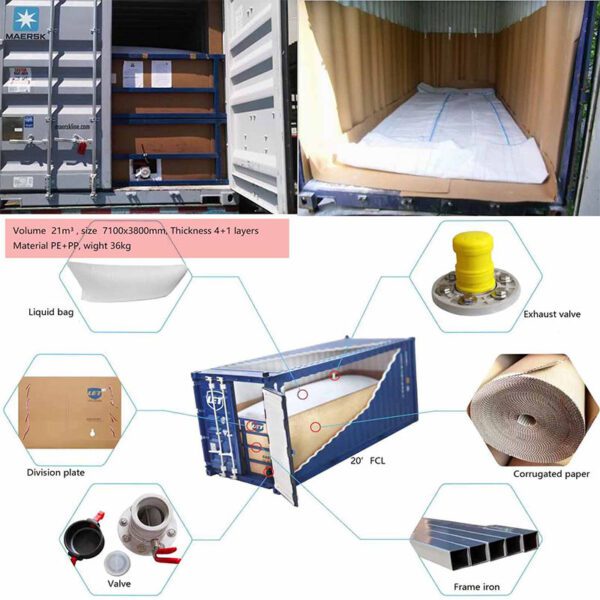

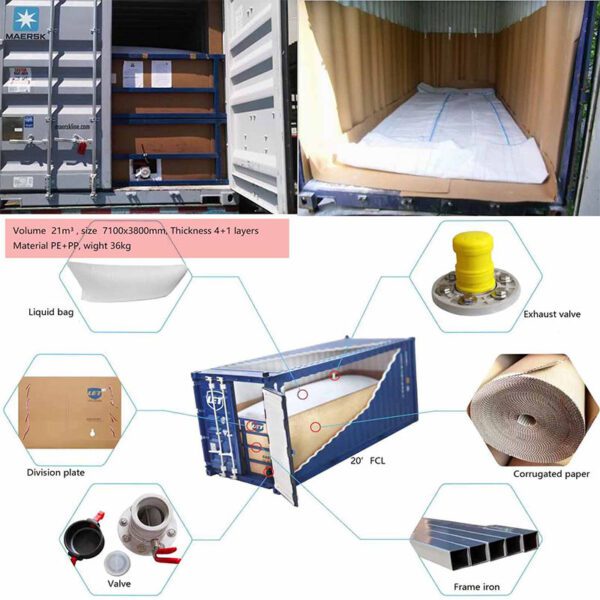

Polypropylene Glycol (PPG) Packaging Information

Metal Drum

IBC Drum

Flexible Bag

ISO Tank

| Cyclohexanone packaging | Capacity | 20GP | 40GP |

| drum | 200 kg /drum | total 80 drums, Net 16 ton | total 120 drums, Net 24.8 ton |

| IBC drum | 1000 kg /IBC | total 20 IBC, Net 20 ton | total 24 IBC, Net 24 ton |

| ISO Tank | 23 ton /ISO Tank | 1 ISO Tank, Net 23 ton | N/A |

For PPG, we welcome you to test and check the quality, if you need a sample please contact our sales team to discuss your sample requirements, we believe that our product quality is suitable for the specific application. We provide samples free of charge but the shipping cost will be borne by you.

Physical and Chemical Properties of PPG

| Molecular Weight | Appearance at 25°C | Hydroxyl Value (mgKOH/g) | Acid Value (mgKOH/g) | Water Content (%) | pH Value (1% aqueous solution) |

|---|---|---|---|---|---|

| PPG-200 | Slightly yellow transparent viscous liquid | 510-623 | 180-220 | ≤0.5 | 5.0-7.0 |

| PPG-400 | Slightly yellow transparent viscous liquid | 255-312 | 360-440 | ≤0.5 | 5.0-7.0 |

| PPG-600 | Slightly yellow transparent viscous liquid | ≤170 | 540-660 | ≤0.5 | 5.0-7.0 |

| PPG-1000 | Slightly yellow transparent viscous liquid | ≤102 | 900-1100 | ≤0.5 | 5.0-7.0 |

| PPG-1500 | Slightly yellow transparent viscous liquid | 68-83 | 1350-1650 | ≤0.5 | 5.0-7.0 |

| PPG-2000 | Slightly yellow transparent viscous liquid | 51-62 | 1800-2200 | ≤0.5 | 5.0-7.0 |

| PPG-3000 | Slightly yellow transparent viscous liquid | ≤34 | 2700-3300 | ≤0.5 | 5.0-7.0 |

| PPG-4000 | Slightly yellow transparent viscous liquid | ≤26 | 3700-4300 | ≤0.5 | 5.0-7.0 |

| PPG-6000 | Slightly yellow transparent viscous liquid | 17-20.7 | 5400-6600 | ≤0.5 | 5.0-7.0 |

| PPG-8000 | Slightly yellow transparent viscous liquid | 12.7-15 | 7200-8800 | ≤0.5 | 5.0-7.0 |

Applications of Polypropylene Glycol (PPG)

PPG Low Molecular Weights (PPG-200, PPG-400, PPG-600)

Consolidated Applications:

– Surfactants and Plasticizers (PPG-200): Utilized extensively in producing detergents and personal care items due to their ability to reduce surface tension and enhance the texture and stability of formulations.

– Personal Care and Pharmaceuticals (PPG-400 and PPG-600): These molecular weights are favored in personal care products for their moisturizing properties in skin and hair applications. In pharmaceuticals, they improve the delivery and effectiveness of drugs by aiding the solubility of active ingredients.

PPG Medium to High Molecular Weights (PPG-1000 to PPG-2000)

Consolidated Applications:

– Functional Fluids and Lubricants (PPG-400 and PPG-1000 to PPG-2000): PPG in this range acts as a base for various industrial lubricants, offering stable performance across temperature extremes, and is used in synthetic lubricants for its anti-wear and friction-reducing properties.

PPG Higher Molecular Weights (PPG-3000 to PPG-8000)

Consolidated Applications:

– Polyurethane Production (PPG-3000 to PPG-8000): As a polyol component in polyurethanes, PPG contributes to the creation of products with enhanced durability, flexibility, and resilience, such as in foams, elastomers, and coatings.

– Adhesives and Sealants (PPG-3000 to PPG-8000): These weights are integral in formulating robust adhesives and sealants, offering strong bonding capabilities and moisture resistance, critical in construction and manufacturing.

– Agricultural Surfactants (PPG-3000 to PPG-8000): In agriculture, PPG enhances the efficacy of pesticides and herbicides, improving the distribution and penetration of these agents on plant surfaces.

Specialized Industrial Applications

Consolidated Applications:

– Defoaming Agents (Various Weights): PPG acts as a defoamer across various molecular weights, mitigating unwanted foam in industrial processes such as paper manufacturing and wastewater treatment.

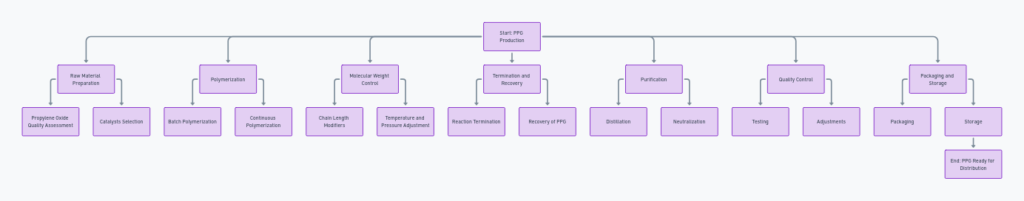

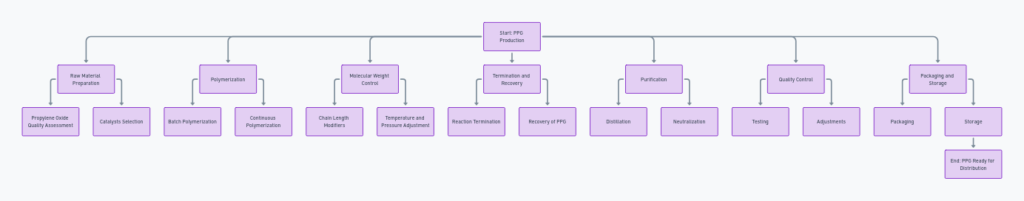

Production Technology of PPG

Polypropylene Glycol (PPG) production typically involves a process known as polymerization, where propylene oxide, a monomer, is reacted to form a polymer. The specific process can vary based on the final PPG product’s desired molecular weight and properties. Here’s a generalized outline of the production process:

1. Raw Material Preparation

– Propylene Oxide: Propylene oxide is the primary raw material for producing PPG. The quality of propylene oxide must be assessed and confirmed to meet the specifications required for PPG production.

– **Catalysts**: Depending on the polymerization process, various catalysts can be used, including acids, bases, or organometallic compounds.

2. Polymerization

– Batch Polymerization: This is commonly used for small-scale production where a measured amount of propylene oxide is reacted in the presence of a catalyst. The reaction is typically carried out in a reactor vessel with temperature control to maintain the required reaction conditions.

– Continuous Polymerization: A continuous process is employed for larger-scale production, where propylene oxide is continuously fed into a reactor with the catalyst. The molecular weight of PPG can be controlled by the reaction time and the amount of catalyst used.

3. Molecular Weight Control

– Chain Length Modifiers: Substances like water or ethylene glycol are often added to control the length of the polymer chain, which determines the molecular weight of the PPG.

– Temperature and Pressure: These conditions are closely monitored and adjusted to direct the polymerization process towards the desired molecular weight range.

4. Termination and Recovery

– Reaction Termination: Once the desired molecular weight is achieved, the reaction is terminated, usually by cooling the reaction mixture or adding a termination agent that stops the polymerization.

– Recovery of PPG: The PPG is then separated from the reaction mixture, which may involve distillation or other purification methods to remove unreacted monomers, catalysts, and by-products.

5. Purification

– Distillation: PPG may undergo a distillation process to purify the product further, mainly to remove low-molecular-weight fractions and ensure the consistency of the final product.

– Neutralization: If acidic or basic catalysts were used, the product might be neutralized to remove residual acidity or alkalinity.

6. Quality Control

– Testing: The final product is tested to meet the required specifications. Tests may include hydroxyl value, acid number, color, moisture content, and molecular weight determination.

– Adjustments: Based on the testing results, further adjustments may be made to the PPG, such as blending with different molecular weight fractions to achieve the desired properties.

7. Packaging and Storage

– Packaging: The final PPG product is packaged in appropriate containers, ranging from small drums to large industrial tanks, depending on the quantity and intended use.

– Storage: PPG should be stored in a cool, dry place to maintain its quality over time. It should also be protected from contamination and excessive heat.

This process can be tailored to produce various PPG grades suitable for multiple industrial and pharmaceutical applications. The specific conditions and catalysts will vary depending on the properties of the desired end product.

How can we handle your order?

step 1

We will communicate with you within 24 hours after you send an enquiry.

step 2

If you need sample testing, we will send samples within 5 days,≤50kg, Express delivery recommended, usually called as DDU service; delivery time 5-7 days. Door to door service.

step 3

If you need bulk goods after the sample test is qualified, we will ship the goods to the port and keep the samples within 6 days after the order is confirmed. Sea shipping recommended, usually called as FOB, CFR, or CIF service.delivery time 10-45 days. Port to port service.

step 4

After waiting for you to receive the goods, we will arrange professional staff to pay a return visit within 7 days.

REQUEST A QUOTE FOR MORE DETAILS

Polypropylene Glycol (PPG) Technical Data

| Name | Poly propylene glycol |

| Molecular Formula | CH4 |

| Molar Mass | 16.04246 |

| Density | 1.01g/mLat 20°C |

| Melting Point | -40 °C |

| Boling Point | >300 °C |

| Flash Point | 230 °C |

| Water Solubility | PRACTICALLY INSOLUBLE |

| Solubility | Insoluble in water. |

| Vapor Presure | <0.01 mm Hg ( 20 °C) |

| Vapor Density | >1 (vs air) |

| Appearance | Transparent liquid |

| Specific Gravity | 1.005 |

| Color | White to light gray |

| Storage Condition | Room Temprature |

| Stability | Stable. Substances to be avoided include strong oxidizing agents. |

| Refractive Index | n20/D 1.451 |

| MDL | MFCD00084446 |

| Physical and Chemical Properties | A colorless to yellowish viscous liquid. |

Qualifications and Documents of PPG

PPG Safety and Handling Information

Storage

PPG should be stored in an excellent, dry location in tightly sealed containers, away from heat sources and direct sunlight. Stainless steel or aluminum containers are typically used to prevent corrosion. Proper storage includes spill containment measures and adherence to the manufacturer’s guidelines for shelf life.

Disposal

Disposal of PPG must comply with environmental regulations. Small quantities can be absorbed and disposed of as chemical waste. At the same time, large volumes may require incineration at a chemical disposal facility. PPG is biodegradable under aerobic conditions but should not be released into waterways due to potential harm to aquatic life.

Safety

Use appropriate personal protective equipment to avoid skin and eye contact during handling and spill cleanup. Contains spills with non-combustible absorbents and is disposed of according to local environmental regulations.

Advantages of the Chinese PPG Market

The global Polypropylene Glycol (PPG) market has experienced substantial growth, with China playing a pivotal role in this expansion. In 2021, the PPG market size was valued at 1.70 million tonnes and is expected to reach new heights by 2028, growing at a Compound Annual Growth Rate (CAGR) of 5.3% from 2021 to 2028, as reported by Intellectual Market Insights Research.

Key Growth Drivers

Surge in Polyurethane Foam Demand

A significant factor propelling the PPG market is the soaring demand for polyurethane (PU) foam, widely utilized across various industries, including construction, automotive, and electronics. The robust growth indicators in these sectors, driven by improving socio-economic factors, are anticipated to catalyze market expansion through 2024.

Polyols as a Primary Chemical

Polyols, with PPG as a primary component, are the most consumed chemicals in the production of PU foam, accounting for over 30% of the total chemical share used in its manufacturing process. The indispensable role of polyols underlines the potential for continued market growth in the PPG sector.

China’s Market Advantages

Innovation and Production Capabilities

China’s emphasis on innovation and extensive manufacturing capabilities provides a solid foundation for the PPG industry’s growth. With a strong manufacturing base and government support, China is poised to maintain its trajectory in the PPG market.

Global Impact

The strategic position of China’s PPG market not only meets the domestic demand but also impacts global supply chains, offering competitive pricing and a diverse product portfolio to international markets. This positions China as a leading exporter in the global PPG landscape.

Future Outlook

The future of the PPG market in China looks promising, with projections indicating continued growth and expansion. The integration of PPG into various industrial applications, with China’s manufacturing strengths and market adaptability, sets the stage for a dynamic and flourishing PPG sector.

FAQs of Polypropylene Glycol (PPG)

Polypropylene Glycol is a synthetic, water-soluble, and biodegradable polymer derived from propylene oxide. It is a type of polyether alcohol known for its versatility in various industrial applications.

PPG is widely used in producing polyurethane foams, personal care products (such as skin creams and deodorants), functional fluids (like antifreeze and hydraulic fluids), and as a solvent or carrier in pharmaceutical formulations.

PPG is produced through a polymerization process where propylene oxide reacts with a catalyst. The process can be controlled to produce PPG of different molecular weights, depending on the intended application.

PPG comes in various molecular weights, each suited for specific applications. Lower molecular weight PPGs are typically used in personal care products, while higher molecular weights are used in industrial applications.

Yes, PPG used in personal care products is generally considered safe. It is non-toxic, does not accumulate in human tissues, and is not a significant irritant or sensitizer when formulated appropriately.

PPG may be used in food products as a direct or indirect additive, subject to regulations by food safety authorities like the FDA. It can act as a humectant, stabilizer, or thickener in various food applications.

PPG should be stored in a cool, dry place, away from direct sunlight and extreme temperatures. It should be kept in well-sealed containers to prevent contamination and moisture absorption.

PPG is considered biodegradable under aerobic conditions. However, it should not be released into the environment in large quantities due to potential harm to aquatic life.

Disposal of PPG should follow local environmental regulations. Small amounts can be treated with absorbents and disposed of as chemical waste. Larger quantities may require special handling and disposal by licensed waste management services.

While PPG has a relatively long shelf life, it can degrade over time, especially if exposed to moisture or heat. It’s best to follow the manufacturer’s guidelines on shelf life and storage conditions.