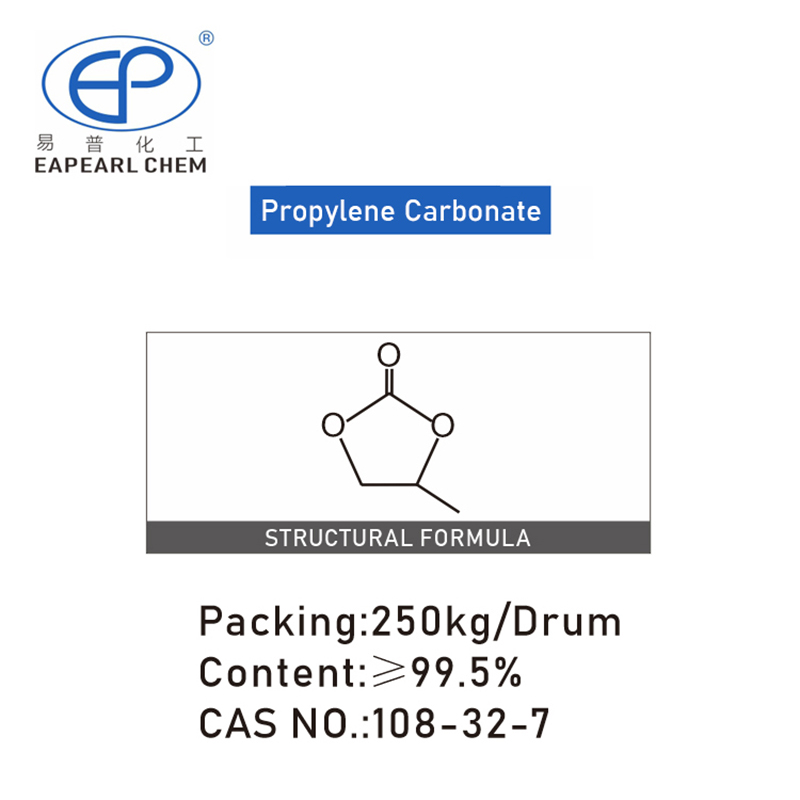

Propylene Carbonate (PC)

| Product Name | Propylene carbonate |

| CAS | 108-32-7 |

| EINECS | 203-572-1 |

| Chemical Formula | C4H6O3 |

| Molecular Weight | 102.09 |

| Purity | ≥99.5% |

| Grade | battery grade, industrial grade |

Are you looking for a chemical with low toxicity, low evaporation rate, and VOCs exemption? Propylene Carbonate has all of those characteristics and it is suitable for a variety of applications. Propylene carbonate also know as 1,2-propanediolcarbonate, 1,2-Propanediyl carbonate, 1,3-dioxolane-2-one,4-methyl, 1-Methylethylene carbonate, 2-Propanediolcycliccarbonate, short for PC. It is a VOC-exempt* clear polar solvent having high boiling and flash points, a low order of toxicity and a mild ether-like odor. It is stable under most conditions and is not hydroscopic or corrosive. It can be used for painting, coating, as a cleaning agent, and as solvent for many other industries.

Due to its low vapor pressure and findings of negligible photochemical reactivity, PC is currently considered VOC exempt by the US EPA. It is also considered a non-VOC according to EU dir 1999/13/EC. Because of its preferable safety and regulatory profile, PC has been a very effective substitute for traditionally used but more hazardous and heavily regulated solvents, including methylene chloride, perchloroethylene, NMP, acetone, MEK, and toluene.

Our propylene carbonate is manufactured to the highest standards, meeting all regulatory requirements and industry specifications. We understand the importance of timely delivery and strive to exceed our customers’ expectations by consistently delivering on time. At Eapearl, we are committed to building strong, long-lasting relationships with our partners, and we are always looking for new opportunities to collaborate and innovate. Our goal is to help our clients achieve their business objectives and drive success in their respective industries. When you choose Eapearl as your propylene carbonate supplier, you can trust that you are getting the best products, the best service, and the best value. We are dedicated to being a reliable and valuable partner for all of your industrial needs.

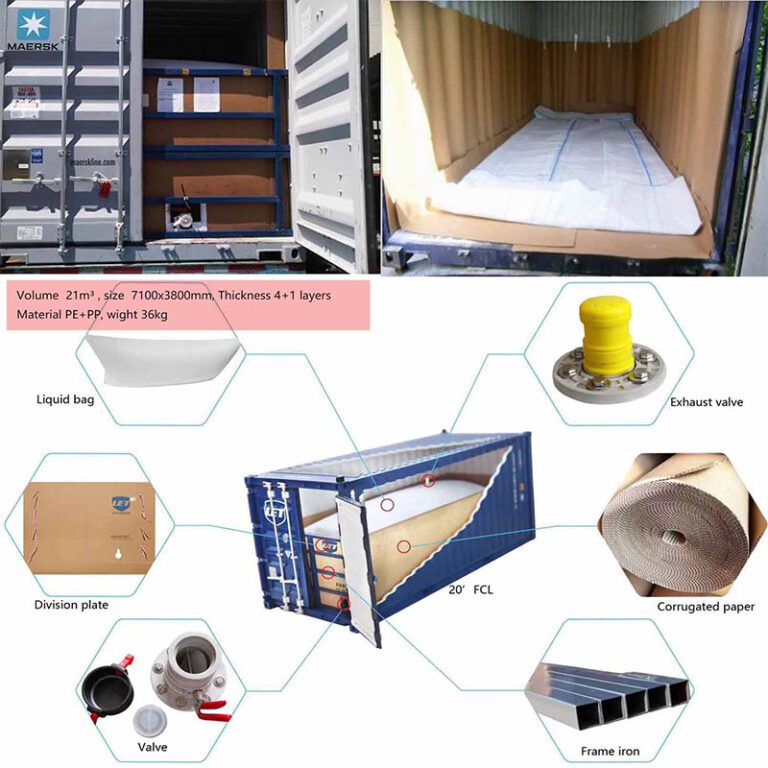

Propylene Carbonate (PC) Packaging Information

Metal Drum

IBC Drum

Flexible Bag

ISO Tank

| PC packaging | capacity | 20GP | 40GP |

| drum | 250 kg /drum | total 80 drums, Net 20 ton | total 104 drums, Net 26 ton |

| IBC drum | 1.2 ton /IBC | total 20 IBC drums, Net 24 ton | total 24 IBC drums, Net 28.8 ton |

| flexibag | 25 ton /flexibag | 1 flexibag, Net 25 ton | N/A |

| ISO Tank | 25 ton /ISO Tank | 1 ISO Tank, Net 25 ton | N/A |

For propylene carbonate, we welcome you to test and check the quality, if you need a sample please contact our sales team to discuss your sample requirements, we believe that our product quality is suitable for the specific application. We provide samples free of charge but the shipping cost will be borne by you.

Preparation of Propylene Carbonate (PC)

At present, the synthesis methods of propylene carbonate mainly include phosgene method, transesterification method, chloropropanol method and propylene oxide and CO2 synthesis method. The cycloaddition reaction of propylene oxide and CO2 to produce propylene carbonate has the advantages of high atomic utilization rate (100%), simple process and environmental friendliness, and has gradually become the main method for the production of propylene carbonate. The following are the general steps of the preparation method.

- Preparation of catalyst: Start by preparing a suitable catalyst, such as a quaternary ammonium salt or an organic base. The catalyst helps facilitate the reaction between propylene oxide and carbon dioxide.

- Reaction setup: In a reaction vessel, combine propylene oxide and carbon dioxide in the presence of the catalyst. The reaction typically takes place under elevated pressure and temperature.

- Reaction conditions: The reaction is typically carried out at temperatures ranging from 100 to 200 degrees Celsius and pressures ranging from 1 to 10 megapascals. These conditions promote the conversion of propylene oxide and carbon dioxide into propylene carbonate.

- Reaction progress: Allow the reaction to proceed for a specific period of time, usually a few hours, while maintaining the desired temperature and pressure. The reaction progress can be monitored by analyzing the reaction mixture at different time intervals.

- Product separation: Once the reaction is complete, separate the propylene carbonate from the reaction mixture. This can be done through various methods, such as distillation, extraction, or crystallization.

- Purification: Purify the obtained propylene carbonate to remove any impurities. This may involve additional distillation or filtration steps. After purification, you will have obtained propylene carbonate, which can be used for various applications.

How can we handle your order?

step 1

We will communicate with you within 24 hours after you send an enquiry.

step 2

If you need sample testing, we will send samples within 5 days,≤50kg, Express delivery recommended, usually called as DDU service; delivery time 5-7 days. Door to door service.

step 3

If you need bulk goods after the sample test is qualified, we will ship the goods to the port and keep the samples within 6 days after the order is confirmed. Sea shipping recommended, usually called as FOB, CFR, or CIF service.delivery time 10-45 days. Port to port service.

step 4

After waiting for you to receive the goods, we will arrange professional staff to pay a return visit within 7 days.

Technical of Propylene Carbonate (PC)

| Name | Propylene carbonate |

| Molecular Formula | C4H6O3 |

| Molar Mass | 102.09 |

| Density | 1.204 g/mL at 25 °C (lit.) |

| Melting Point | -55 °C (lit.) |

| Boling Point | 240 °C (lit.) |

| Flash Point | 270°F |

| Water Solubility | 240 g/L (20 ºC) |

| Solubility | 240g/l |

| Vapor Presure | 0.13 mm Hg ( 20 °C) |

| Appearance | Liquid |

| Color | Clear |

| Odor | odorless |

| Maximum wavelength(λmax) | λ: 235 nm Amax: 1.00 λ: 280 nm Amax: 0.50 λ: 300 nm Amax: 0.30 λ: 350 nm Amax: 0.05 λ: 375-400 nm Amax: 0.01 |

| BRN | 107913 |

| pKa | 3.92[at 20 ℃] |

| PH | 7.0 (200g/l, H2O, 20℃) |

| Storage Condition | Store below +30°C. |

| Stability | Stable. Incompatible with strong oxidizing agents, acids, bases, reducing agents. Protect from contact with moist air or water. |

| Physical and Chemical Properties | Colorless and odorless flammable liquid. melting point -49.2 ℃ boiling point 238.4 ℃ relative density 1.2047 refractive index 1.4218 flash point 128 ℃ solubility, benzene, chloroform, ethyl acetate and other miscible, soluble in water and carbon tetrachloride. |

| LogP | -0.41 at 20℃ |

| Toxicity | LD50 orally in Rabbit: > 5000 mg/kg LD50 dermal Rabbit > 20000 mg/kg |

| HS Code | 29209010 |

| Specific Gravity | 1.209 (20/4℃) |

| EINECS | 203-572-1 |

| explosive limit | 1.8-14.3%(V) |

Downloadable Documents of Propylene Carbonate (PC)

COA of PC

TDS of PC

MSDS of PC

REQUEST A QUOTE FOR MORE DETAILS

Characteristics of Propylene Carbonate (PC)

Propylene carbonate is a versatile compound with several notable characteristics. Here are some key features of propylene carbonate:

Excellent Solubility: Propylene carbonate has a high solubility in both polar and non-polar solvents. This property makes it a useful solvent for a wide range of applications.

Enhanced Drug Solubility and Bioavailability: Propylene carbonate can improve the solubility and bioavailability of poorly soluble drugs. It is often used as a co-solvent in pharmaceutical formulations to enhance drug delivery.

High Conductivity: Propylene carbonate exhibits high electrical conductivity, making it suitable for use in electrolytes for lithium-ion batteries and supercapacitors.

Good Thermal Stability: Propylene carbonate has a high boiling point and good thermal stability, allowing it to be used in high-temperature applications.

Low Toxicity: Propylene carbonate is considered to be relatively safe and has low toxicity. It is commonly used in cosmetic and personal care products.

Low Volatility: Propylene carbonate has a low vapor pressure, which means it has low volatility and does not readily evaporate. This property makes it suitable for applications where low evaporation rates are desired.

These characteristics make propylene carbonate a valuable compound in various industries, including cosmetics, pharmaceuticals, oil and gas, electronics, and coatings.

Propylene Carbonate (PC) Applications

Lithium-ion batteries and Electronics

Propylene carbonate is an important cyclic carbonate solvent used in lithium-ion batteries (LIB) electrolytes. Its high dielectric constant of 64 makes it a valuable component in electrolytes for lithium batteries, often used in combination with low-viscosity solvents(e.g. dimethoxyethane). This combination helps enhance the performance and stability of the battery. In addition to its use in lithium batteries, propylene carbonate is also utilized as an effective circuit board and electronic cleaner. It is commonly used in the manufacturing of computers, cell phones, hybrid vehicles, and plug-in hybrid electric vehicles. Its solvent properties make it suitable for cleaning and degreasing electronic components.

Paint & Coatings

Propylene carbonate is used as a high-boiling solvent and film-forming auxiliary, especially in poly (vinyl fluoride) and poly (vinylidene fluoride) systems. It is also employed as an auxiliary in the pigment and dye industry. Propylene Carbonate is also more eco-efficient compared to other solvents used in wire enamel coating applications. As a reactive diluent, it can reduce the viscosity of isocyanates or polyurethane pre-polymers in two-component polyurea systems.

Cleaning, Stripping and Degreasing

Propylene carbonate has low toxicity and rapid biodegradability properties for solvents used in hard surface cleaning and degreasing formulations. Alone or combined with other solvents, it is effective as a polyurethane and polymer/resin cleaner, for cleaning up unsaturated polyester resins and gelcoats, as an all-purpose industrial and consumer cleaner, for cleaning stereolithographic parts, and as an ink cleaner.

Gas Treating and Petrochemical Applications

Propylene Carbonate is used as a physical solvent for removal of carbon dioxide (CO2) and hydrogen sulfide (H2S) in natural gas treating, oil pyrolysis gas, and synthetic ammonia conversion gas applications. It is also used as an oil solvent and as an extraction agent for olefins and aromatics. In Grignard reactions, it is used as an intermediate to create tertiary alcohols.

Other Uses and Applications

Propylene carbonate is used as a binder for foundry sand molds, as a plasticizer for polymers, and in pesticide formulations.

In the textile industry can be used as synthetic fiber additives and fixatives, spinning solvents, or water-solvent dye pigment dispersant.

Propylene Carbonate is not corrosive, therefore, it can be used in cosmetic and personal care products like make-up, antiperspirants, hair conditioners, and other products.

If you have specific questions or need more detailed information about any of these applications, feel free to ask. I’m here to provide the insights you need for your business considerations.

REQUEST A QUOTE FOR MORE DETAILS

Knowledge Base of Propylene Carbonate (PC)

Feedback of Propylene Carbonate (PC)

Ata Karimi, Turkey

I am highly satisfied with the propylene carbonateprovided by your company for making cleaners and paint strippers. The exceptional dissolution capacity of the ester has significantly enhanced the performance of our industrial cleaning formulas. It effectively removes stubborn stains and coatings, making our cleaning processes more efficient and effective. The quality and reliability of your product have greatly contributed to our success in delivering high-quality cleaning solutions. We highly recommend your carbonic acid ester for its outstanding performance and its valuable contribution to our business.

Usman Ahmad, Pakistan

Your Propylene Carbonate is a vital component in our pigment dispersants. The excellent solubility significantly improves dispersion, ensuring high-quality results in our formulations. Its reliability and consistent performance have made it an essential choice for enhancing the color dispersion process. We appreciate the value it adds to our pigment-related applications.

Our Team

FAQs of Propylene Carbonate (PC)

A1: Our propylene carbonate are of high quality with a purity of over 99.5% and meet all industry standards. It has been carefully manufactured and tested to ensure excellent performance and reliability in a variety of applications.

A2: Sure, we’re equipped to handle large-volume orders and guarantee consistent supply. Our robust production capabilities and efficient logistics network enable us to meet high demand while maintaining the quality and reliability that our customers expect.

A3: Propylene carbonate is used in cosmetics and personal care products due to its excellent solubility, low toxicity, and ability to enhance product stability. It acts as a solvent for various ingredients, ensuring efficient formulation and improved product performance.

A4: The Food and Drug Administration (FDA) has reviewed the safety of Propylene Carbonate and approved its use as an indirect food additive Indirect food additives are additives that may become part of the food in trace amounts due to its packaging, storage or other handling. The safety of Propylene Carbonate has been assessed by the Cosmetic Ingredient Review The Cosmetic Ingredient Review (CIR) was established in 1976 as an independent safety review program for cosmetic ingredients. The CIR includes participation by the U.S. Food & Drug Administration and the Consumer Federation of America. Expert (CIR) Panel. The CIR Expert Panel evaluated the scientific data and concluded that Propylene Carbonate was safe as a cosmetic ingredient in the present practices of use and concentration.

A5: Absolutely. We offer 100g-200g samples, with the client only covering shipping costs.

A6: Standard lead times are approximately 2-4 weeks, varying based on order size and destination.

A7: Our standard payment terms include a 30% advance and the balance against delivery, but terms can be negotiated for long-term partnerships.

A8: Yes, we offer comprehensive after-sales support, addressing any post-purchase queries or concerns.

A9: As a supplier, in order to provide you with an accurate quote for your product, please inform us of the quantity you require, the required purity specifications, any specific packaging needs, your shipping location, and whether your application requires any customization requirements or certifications.