Premium Propylene glycol - a universal solution for your production needs!

Discover How Our High-Quality Propylene Glycol Is Revolutionizing Applications in Food, Cosmetics, Pharmaceuticals, and Beyond

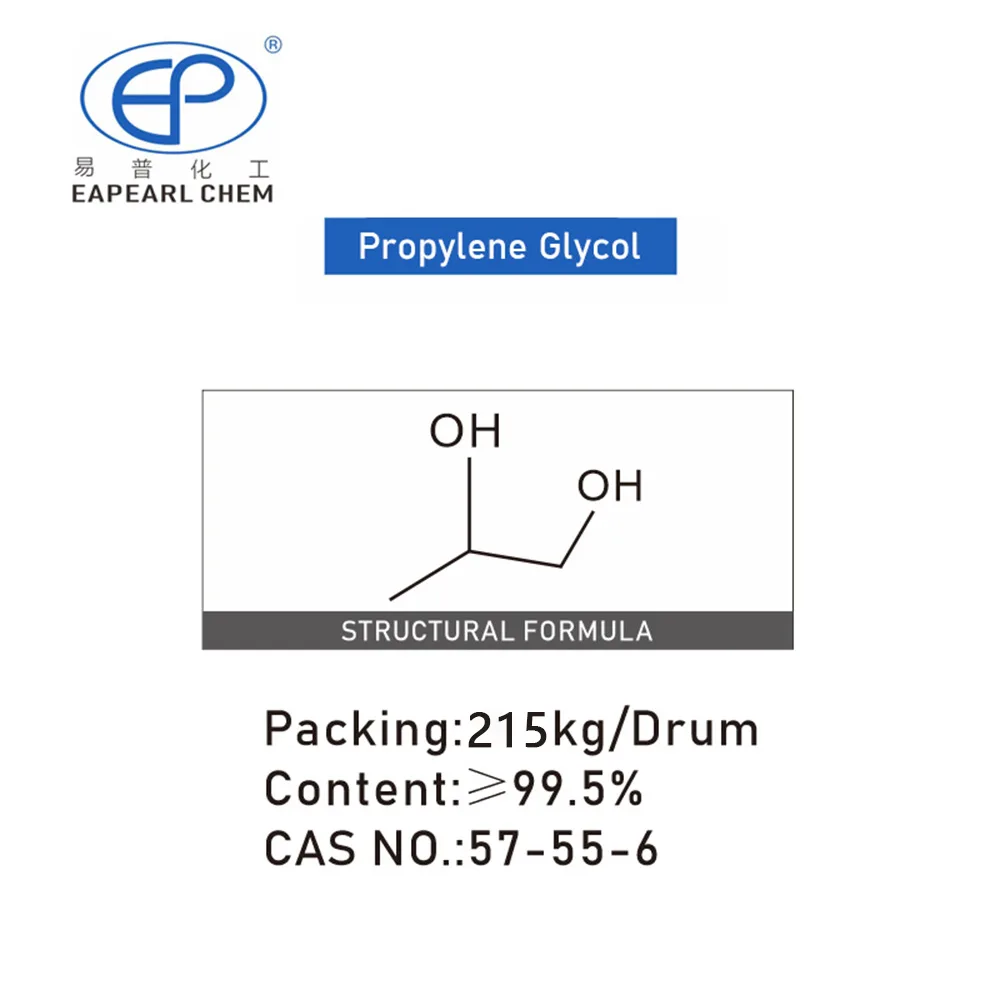

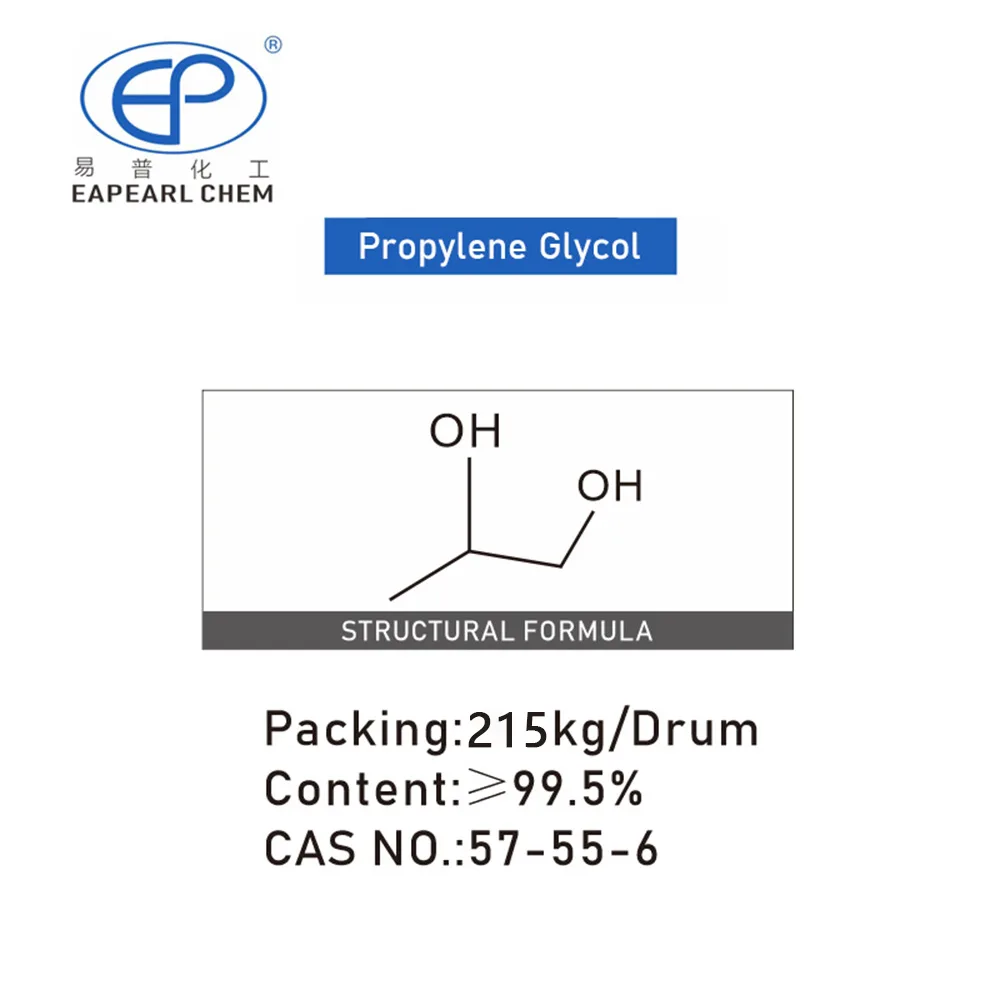

| Product Name: | Propylene Glycol |

| CAS No.: | 57-55-6 |

| EINECS.: | 200-338-0 |

| chemical formula: | C3H8O2 |

| molecular weight: | 76.09 |

| Purity | ≥99.5% |

| Packing: | 215kg/drum |

Propylene glycol, also known as 1,2-propanediol, mono propylene glyco, Propane-1,2-diol, Propylene glycol 57-55-6, is a versatile chemical with a broad spectrum of applications across numerous industries. Renowned for its excellent properties as a humectant and solvent, propylene glycol is a fundamental ingredient in personal care, food, and pharmaceutical products, enhancing their texture, stability, and absorption.

In personal care and cosmetic formulations, propylene glycol significantly improves the skin’s moisture retention and contributes to the effectiveness of hair care products. Its role in the food industry is equally vital, serving as a safe food additive that improves texture and stability, while in pharmaceuticals, it acts as a solvent and carrier for active ingredients. Propylene glycol’s utility extends to industrial applications as well. It’s a key component in antifreeze and de-icing solutions, and its hygroscopic nature makes it valuable in the production of certain plastics and as a stabilizer in various chemical reactions.

Choosing Eapearl’s propylene plycol means opting for a product that embodies quality and reliability. With a legacy of over 15 years, Eapearl understands the critical need for consistent, high-quality supply in maintaining efficient and uninterrupted operations. Partnering with Eapearl not only provides you with a superior chemical product but also a comprehensive solution that enhances the quality and functionality of your end products. Our dedication to excellence and efficient logistics ensures that your operations benefit from the best propylene glycol on the market, solidifying your path to long-term industrial success.

Propylene Glycol (PG) Information

| MPG packaging | capacity | 20GP | 40GP |

| drum | 215 kg /drum | total 80 drums, Net 17.2 ton | total 112 drums, Net 24.08 ton |

| IBC | 1 ton /IBC | total 20 IBC, Net 20 ton | total 26 IBC, Net 26 ton |

| flexibag | 25 ton /flexibag | 1 flexibag, Net 25 ton | N/A |

| ISO Tank | 25 ton /ISO Tank | 1 ISO Tank, Net 25 ton | N/A |

For propylene glycol, we welcome you to test and check the quality, if you need a sample please contact our sales team to discuss your sample requirements, we believe that our product quality is suitable for the specific application, we provide samples free of charge but the shipping cost will be borne by you.

Process for the Preparation of Propylene Glycol (PG)

1, 2-propylene glycol can be prepared by a variety of methods, the most common of which is preparation from propylene. Specifically, it can be prepared by several methods:

Direct Hydrolysis of Propylene Oxide with Water: This is a straightforward process where propylene oxide (PO) is directly reacted with water to produce propylene glycol. A catalyst is often used to facilitate the reaction. This method is efficient and straightforward, making it a popular choice for propylene glycol production.

Chlorohydrin Process: This process starts with propylene (also known as propene), which is a three-carbon alkene with a carbon-to-carbon double bond. The propylene is first reacted with chlorine and water to form propylene chlorohydrin. The propylene chlorohydrin is then converted into propylene oxide. Finally, the propylene oxide is hydrated to form propylene glycol.

Peroxidation Process: Similar to the chlorohydrin process, this method also begins with propylene. In this process, propylene is oxidized (typically using a peroxide) to create propylene oxide. The propylene oxide is then hydrated, similar to the other processes, to produce propylene glycol.

Both the chlorohydrin and peroxidation processes involve the formation of propylene oxide as an intermediate step. However, the initial reactions and byproducts differ between these methods. The direct hydrolysis of propylene oxide is more straightforward but relies on the availability of propylene oxide, which can be produced via the other two methods. Each of these processes has its own set of advantages, costs, and environmental considerations, influencing their use in commercial production.

How can we handle your order?

step 1

We will communicate with you within 24 hours after you send an enquiry.

step 2

If you need sample testing, we will send samples within 5 days,≤50kg, Express delivery recommended, usually called as DDU service; delivery time 5-7 days. Door to door service.

step 3

If you need bulk goods after the sample test is qualified, we will ship the goods to the port and keep the samples within 6 days after the order is confirmed. Sea shipping recommended, usually called as FOB, CFR, or CIF service.delivery time 10-45 days. Port to port service.

step 4

After waiting for you to receive the goods, we will arrange professional staff to pay a return visit within 7 days.

Technical of Propylene Glycol (PG)

| Propylene glycol for short | PG/MPG |

| Molecular Formula | C3H8O2 |

| Molar Mass | 76.09 |

| Density | 1.036 g/mL at 25 °C (lit.) |

| Melting Point | -60 °C (lit.) |

| Boling Point | 187 °C (lit.) |

| Specific Rotation(α) | n20/D 1.432 (lit.) |

| Flash Point | 225°F |

| JECFA Number | 925 |

| Water Solubility | miscible |

| Solubility | Miscible in water, acetone, ethyl acetate and chloroform, soluble in ether. It can be dissolved in many essential oils, but cannot be miscible with petroleum ether, paraffin and grease. |

| Vapor Presure | 0.08 mm Hg ( 20 °C) |

| Vapor Density | 2.62 (vs air) |

| Appearance | Viscous Liquid |

| Color | APHA: ≤10 |

| Odor | Practically odorless |

| Merck | 147,855 |

| BRN | 1340498 |

| pKa | 14.49±0.20(Predicted) |

| PH | 6-8 (100g/l, H2O, 20℃) |

| Storage Condition | Store at +5°C to +30°C. |

| Sensitive | Hygroscopic |

| Explosive Limit | 2.4-17.4%(V) |

| Refractive Index | n20/D 1.432(lit.) |

| MDL | MFCD00064272 |

| Physical and Chemical Properties | Colorless, viscous and stable water-absorbing liquid, almost tasteless and odorless. melting point -60 ℃ boiling point 187.3 ℃ relative density 1.0381 refractive index 1.4326 flash point 99 ℃ solubility, ethanol and a variety of organic solvents miscible. |

| LogP | -0.92 |

| Toxicity | LD50 orally in Rabbit: 19400 – 36000 mg/kg LD50 dermal Rabbit 20800 mg/kg |

| Flammability | Lower flammable limit: 2.6% by volume; Upper flammable limit: 12.5% by volume |

| HS Code | 29053200 |

| Specific Gravity | 1.038 (20/20℃)1.036~1.040 |

Downloadable Documents of Propylene Glycol (PG)

COA

COA of USP MPG

TDS

TDS of USP MPG

MSDS

MSDS of MPG

For Mono Propylene Glycol we can provide reach certificate, details can be obtained by submitting an enquiry.

REQUEST A QUOTE FOR MORE DETAILS

Propylene Glycol (PG) Application

Propylene glycol is a versatile chemical compound with a wide range of applications across various industries. Here are some of its primary uses:

Non-Toxic Antifreeze & De-icing Fluid

The switch in antifreeze formulation from ethylene glycol to propylene glycol was indeed made for safety reasons, as ethylene glycol is toxic. Ethylene glycol is highly toxic when ingested and is metabolized into calcium oxalate crystals in the body, which can accumulate in vital organs such as the heart, lungs and kidneys, causing serious damage and even death. Another danger of ethylene glycol is its characteristic sweet smell and taste, which can be tempting to children and animals, and accidental ingestion can cause serious or fatal consequences.

Propylene glycol is a much safer alternative. If ingested, it is metabolized into acetic acid (vinegar) and pyruvic acid, both of which are non-toxic and naturally occurring in the body. Like ethylene glycol, propylene glycol also effectively lowers the freezing point of water by disrupting the formation of ice crystals. This makes it a suitable and safer substitute for antifreeze applications and also makes it a de-icing solution for aircraft and runways.

Unsaturated Polyester Resins (UPR)

Propylene glycol is a significant component in the production of synthetic resins, particularly unsaturated polyester resins (UPR), in the paints and plastics industries. The statistic that 45% of produced propylene glycol is used as a chemical feedstock for these resins underscores its importance.

The inclusion of PG in resin formulations affects various properties of the final product, such as flexibility, durability, and chemical resistance. Unsaturated polyester resins find extensive use in various sectors. They are commonly used in the automotive industry for body fillers, in marine applications for boat hulls, in the construction industry for laminates, and in the manufacturing of fiberglass products. Propylene glycol is favored in resin production due to its relatively lower toxicity compared to other glycols. This makes UPRs more environmentally friendly and safer for workers during manufacturing and application.

Food Industry

One of the reasons for propylene glycol widespread use in food is its non-reactive nature. Propylene glycol does not react with other ingredients in food, allowing it to perform its intended function without altering the taste, color, or texture of the product.

As a humectant, propylene glycol is effective in attracting and retaining moisture. This property is especially beneficial in products like baked goods, where it helps maintain moisture, texture, and freshness. By keeping these foods moist, it also aids in their preservation. Its hygroscopic nature means it can attract both water-based and oil-based substances, leading to homogenous distribution in mixtures. By helping to retain moisture and prevent drying out, propylene glycol indirectly acts as a preservative, extending the shelf life of food products.

In summary, propylene glycol is particularly valuable because of its ability to improve the shelf life, texture and consistency of foods without compromising their safety or quality.

Pharmaceuticals

In oral formulations, PG serves as a solvent for insoluble drugs, improving their absorption and bioavailability. PG enhances the absorption of active ingredients through the skin or mucosal tissues, making it effective in creams, ointments, and gels. In intravenous (IV) drugs, PG is valuable for its ability to dissolve substances that have poor water solubility, ensuring efficient delivery of the drug into the bloodstream. PG’s role as a drug stabilizer is significant in extending the shelf life and maintaining the effectiveness of pharmaceuticals. Its excellent miscibility with water makes it an ideal solvent for various pharmaceutical formulations.

Concerns about the toxicity of propylene glycol are mitigated by its metabolic breakdown within the body. Typically, it is metabolized and excreted within 48 hours. It does not form harmful crystals or accumulate in the body (non-bio-accumulative), making it a safer choice compared to other solvents with similar uses.

Cosmetics and personal care products

Propylene glycol is an effective humectant, which means it helps retain moisture in the skin. This property makes it a popular ingredient in moisturizers, lotions, and creams, where it helps maintain the skin’s hydration levels. In various personal care products, PG acts as a solvent and carrier agent. It dissolves and evenly distributes active ingredients or fragrances in the product, ensuring consistent performance and scent. PG can enhance the penetration of other ingredients into the skin, making it useful in products where deeper skin absorption is desired. It plays a role in improving the texture and stability of personal care products. This includes maintaining the consistency and preventing the separation of ingredients in lotions and creams.

If you have specific questions or need more detailed information about any of these applications, feel free to ask. I’m here to provide the insights you need for your business considerations.

REQUEST A QUOTE FOR MORE DETAILS

Knowledge Base of Propylene Glycol (PG)

Feedback of Propylene Glycol (PG)

Mikhail Smirnov, Russia

I’m writing from Russia to commend your propylene glycol for its excellent performance in our gas pipelines. Despite our harsh winters, it has prevented freezing efficiently, ensuring continuous flow and operations. Its environmental safety and cost-effectiveness are particularly impressive. Your team’s support has been invaluable. We’re thoroughly satisfied and look forward to future collaborations.

Chris Tremblay, Canada

We recently integrated your propylene glycol into our coating formulations and are immensely impressed. It’s significantly enhanced our products’ durability and performance across diverse environmental conditions. We’ve observed remarkable improvements in lifespan and resilience, particularly in extreme climates. Your product’s consistent quality and reliability have greatly contributed to our success. We value this partnership and look forward to future collaborations.

FAQs of Propylene Glycol (PG)

A1: As a supplier, we ensure our propylene glycol is of the highest quality, meeting strict purity standards, and is consistent, safe, and compliant with all relevant industry regulations and certifications.

A2: Sure, we’re equipped to handle large-volume orders and guarantee consistent supply. Our robust production capabilities and efficient logistics network enable us to meet high demand while maintaining the quality and reliability that our customers expect.

A3: YES, we assure that our propylene glycol is certified as food-grade by relevant food safety authorities. It meets stringent standards set by the FDA and EU regulatory bodies, ensuring it’s safe and suitable for use in food applications.

A4: As a supplier, we prioritize safety and quality. Our propylene glycol is non-toxic and rigorously tested to ensure its safety for use in products applied to the skin or ingested. It complies with the strictest safety standards, making it a reliable choice for cosmetic and pharmaceutical applications.

A5: we manage our supply chain with strategic planning and partnerships to ensure consistent availability. We maintain robust relationships with raw material providers, invest in efficient logistics, and utilize advanced forecasting methods. This approach allows us to reliably meet customer demands while mitigating supply chain disruptions.

A6: Our minimum order quantity for propylene glycol is 1 ton. We also offer price discounts for larger volume orders, providing a cost-effective solution for customers needing bulk quantities. Of course, we also provide samples 100g-200g only charge shipping.

A7: The average lead time for the delivery of our products, including propylene glycol, ranges from 7 to 40 days following order confirmation. This timeframe varies depending on your specific location and the size of your order. We strive to ensure timely and efficient delivery to meet our customers’ needs.

A8: As a supplier, in order to provide you with an accurate quote for your product, please inform us of the quantity you require, the required purity specifications, any specific packaging needs, your shipping location, and whether your application requires any customization requirements or certifications.