Polytetrahydrofuran (PTMEG)

Polytetrahydrofuran (PTHF), also known as polytetramethylene ether glycol (PTMEG), is a polymer of tetrahydrofuran (THF). This versatile polyether is known for its elasticity, resilience, and chemical stability, making it a valuable material in various industrial applications.

Alias

- Polytetrahydrofuran (PTHF)

- Polytetramethylene ether glycol (PTMEG)

- PolyTHF

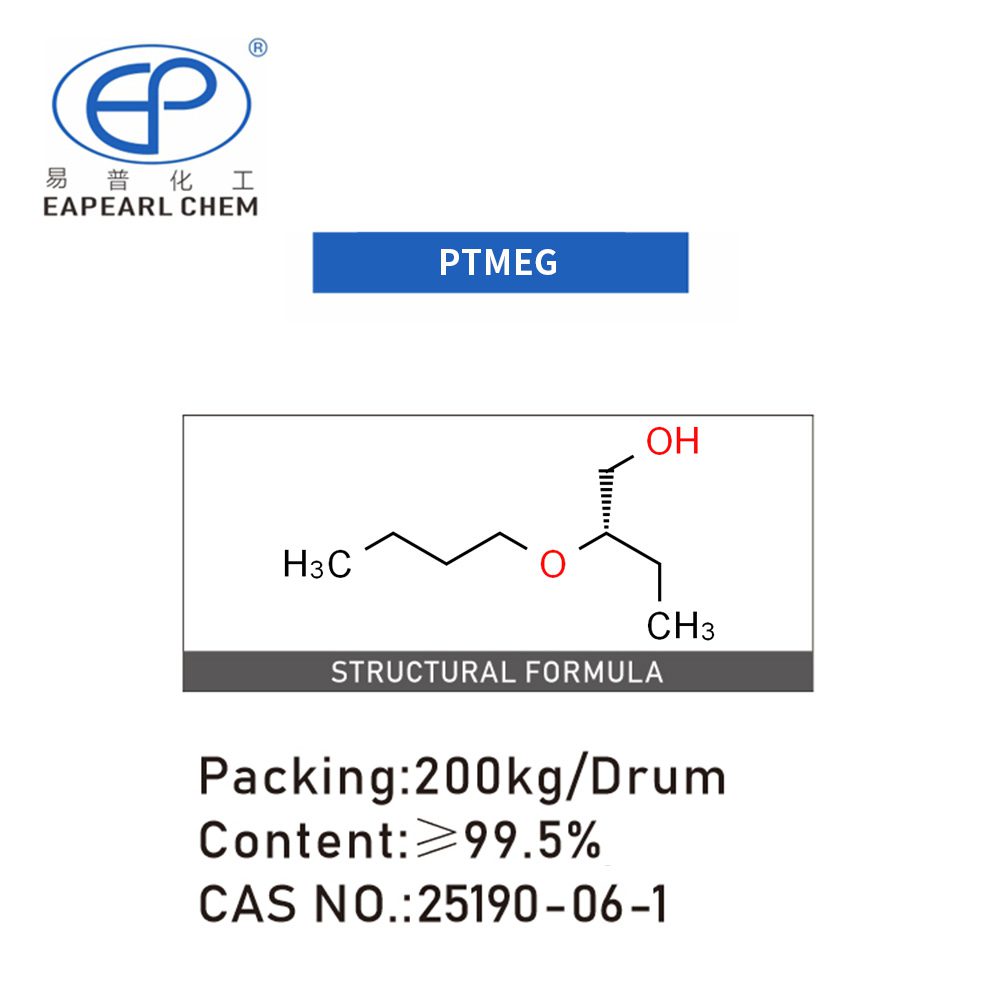

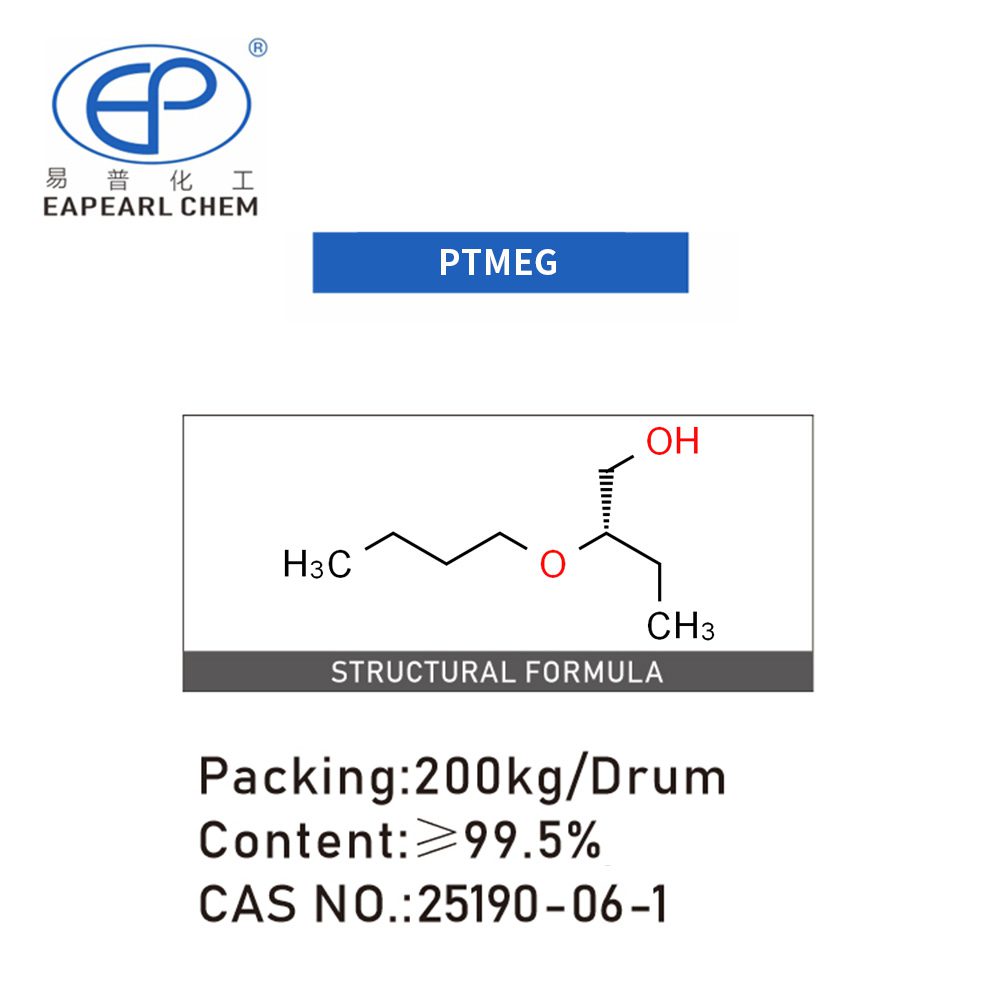

Chemical Structure

- Monomer Unit: The monomer for polytetrahydrofuran is tetrahydrofuran (THF), which has the chemical formula C4H8O.

- Polymerization: The polymerization of THF yields polytetrahydrofuran, with the repeating unit (−O−(CH2)4−).

Properties

- Physical State: Typically, PTMEG is a colorless, viscous liquid or a waxy solid, depending on its molecular weight.

- Solubility: It’s soluble in many organic solvents like chloroform and acetone but is insoluble in water.

- Molecular Weight: The molecular weight of PTMEG can vary, which influences its physical properties. Higher molecular weight PTMEG tends to be more viscous.

PTMEG Packaging Information

| PTMEG packaging | Capacity | 20GP | 40GP |

| drum | 200 kg /drum | total 80 drums, Net 16 ton | total 130 drums, Net 26 ton |

| IBC drum | 1 ton /IBC drum | total 20 IBC drums, Net 20 ton | total 26 IBC drums, Net 26 ton |

| flexibag | 25 ton /flexibag | 1 flexibag, Net 25 ton | N/A |

| ISO Tank | 25 ton /ISO Tank | 1 ISO Tank, Net 25 ton | N/A |

For PTMEG, we welcome you to test and check the quality, if you need a sample please contact our sales team to discuss your sample requirements, we believe that our product quality is suitable for the specific application, we provide samples free of charge but the shipping cost will be borne by you.

Applications of PTMEG

Polytetramethylene ether glycol (PTMEG) is a versatile polymer used in various industries due to its unique properties. Below are detailed descriptions of its specific applications:

Spandex Fibers

One of the most significant applications of polytetrahydrofuran is in the production of spandex fibers. Spandex, known for its exceptional elasticity, relies heavily on PTMEG for its unique properties.

- Elasticity and Stretchability: PTMEG provides the necessary stretch and recovery characteristics, making spandex ideal for use in athletic wear, swimwear, and other garments that require high elasticity.

- Durability: The polymer’s resilience ensures that the spandex fibers maintain their shape and elasticity over time, even with frequent stretching and washing.

- Comfort: The smooth texture of PTMEG contributes to the comfort of spandex fabrics, making them soft and pleasant to wear.

Polyurethane Elastomers

Polytetrahydrofuran is a critical component in the production of polyurethane elastomers, which are used in a variety of flexible and durable products.

- Flexible Foams: In furniture and automotive seating, PTMEG-based polyurethane foams provide cushioning and support while retaining flexibility and comfort.

- Coatings: PTMEG is used in polyurethane coatings to enhance their flexibility, chemical resistance, and durability. These coatings are applied to floors, fabrics, and various industrial surfaces.

- Adhesives and Sealants: Polyurethane adhesives and sealants formulated with PTMEG exhibit excellent bonding strength, elasticity, and resistance to environmental factors, making them suitable for construction and automotive applications.

Thermoplastic Polyurethanes (TPU)

Thermoplastic polyurethanes (TPU) are another significant application of PTMEG, offering a unique combination of properties that are highly valued in several industries.

- Footwear: TPU is used in the soles of athletic shoes for its durability, flexibility, and resistance to abrasion. It enhances comfort and performance in sports and casual footwear.

- Medical Devices: TPU’s biocompatibility and flexibility make it ideal for medical applications such as catheters, tubing, and various implantable devices.

- Electronics: In the electronics industry, TPU is used for cable sheathing and protective coverings due to its flexibility and resistance to wear and tear.

Elastomeric Fibers

In addition to spandex, polytetrahydrofuran is used in other elastomeric fibers that require similar properties.

- Stretch Fabrics: PTMEG-based elastomeric fibers are used in various textiles to provide stretch and recovery, enhancing the comfort and fit of garments.

- Compression Wear: Medical and athletic compression garments benefit from PTMEG’s elasticity, which helps improve circulation and support muscles.

Industrial Applications

Polytetrahydrofuran finds use in various industrial applications due to its chemical stability and versatility.

- Hydraulic Fluids and Lubricants: PTMEG’s non-volatile and stable nature makes it suitable for hydraulic fluids and lubricants, providing reliable performance under varying temperatures and pressures.

- Additives: PTMEG is used as an additive in different formulations to enhance flexibility, reduce brittleness, and improve overall performance in industrial products.

Polytetramethylene ether glycol (PTMEG) is a highly valuable polymer with a broad range of applications. Its unique properties of elasticity, durability, and chemical stability make it essential in the production of spandex fibers, polyurethane elastomers, thermoplastic polyurethanes, elastomeric fibers, and various industrial products. The versatility of PTMEG continues to drive innovation across multiple industries, highlighting its importance in modern manufacturing and product development.

REQUEST A QUOTE FOR MORE DETAILS

Technical Data of PTMEG

| Name | Polytetramethylene ether glycol |

| Synonyms | PTMEG; Polytetrahydrofuran (PTHF); PolyTHF; PTMG; polifurit; b2000; hiprenemc532; Terathane 1400; terathane(R) 1400; terathane(R) 1400; Poly(tetrahydrofuran); poly(oxy-1,4-butylene)glycol; |

| CAS | 25190-06-1 |

| EINECS | 607-637-9 |

| Molecular Formula | C16H33O5X2 |

| Molar Mass | 305.43 |

| Density | 1g/mLat 25°C |

| Melting Point | 33-36°C |

| Boling Point | 195.7°C at 760 mmHg |

| Flash Point | >230°F |

| Vapor Presure | <0.01 mm Hg ( 25 °C) |

| Specific Gravity | 0.961 |

| PH | 7 (H2O, 20℃)Aqueous solution |

| Storage Condition | Store below +30°C. |

| Refractive Index | n20/D 1.465 |

| Physical and Chemical Properties | Polytetrahydrofuran is a white waxy solid that dissolves readily in alcohols, esters, ketones, aromatic hydrocarbons, and chlorinated hydrocarbons, and is insoluble in ester hydrocarbons and water, and becomes a transparent liquid when the temperature exceeds room temperature. |

| HS Code | 3907 20 20 |

| Toxicity | LD50 orally in Rabbit: > 5000 mg/kg |

| PH | 7 (H2O, 20℃)Aqueous solution |

| solubility | <10g/l |

| Specific Gravity | 0.961 |

Production Process of Polytetrahydrofuran

Polytetrahydrofuran (PTHF) is produced through the polymerization of tetrahydrofuran (THF). The production process involves several key steps, from the preparation of THF to the polymerization and purification of the final product. Below is a detailed description of the specific production process for polytetrahydrofuran.

1. Preparation of Tetrahydrofuran (THF)

Tetrahydrofuran (THF) is typically derived from the dehydration of 1,4-butanediol or through the catalytic hydrogenation of furan. The quality and purity of THF are critical for the successful production of PTHF.

Dehydration of 1,4-Butanediol: 1,4-Butanediol is dehydrated in the presence of a strong acid, such as sulfuric acid, to produce THF.

HO-(CH2)4-OH→C4H8O+H2OCatalytic Hydrogenation of Furan: Furan is hydrogenated in the presence of a catalyst, such as a nickel or palladium catalyst, to produce THF.

C4H4O+3H2→C4H8O

2. Purification of Tetrahydrofuran (THF)

The THF obtained from the preparation step is purified to remove any impurities that might interfere with the polymerization process. This is typically done through distillation.

- Distillation: THF is distilled under reduced pressure to achieve high purity levels, essential for consistent and high-quality PTHF production.

3. Polymerization of Tetrahydrofuran

The polymerization of THF to produce polytetrahydrofuran is carried out using cationic ring-opening polymerization. This process involves several steps, including initiation, propagation, and termination.

Initiation: A strong acid catalyst, such as boron trifluoride etherate (BF₃·OEt₂), is added to the purified THF. The catalyst initiates the ring-opening polymerization by protonating the oxygen atom in THF, making it more electrophilic.

C4H8O+H+→C4H8O+Propagation: The activated THF monomer reacts with additional THF molecules, forming a growing polymer chain. The propagation continues until the desired molecular weight is achieved.

C4H8O++n(C4H8O)→[-O-(CH2)4-]n+- Termination: The polymerization reaction is terminated by adding a terminating agent, such as water or alcohol, which neutralizes the catalyst and caps the polymer chain ends.

- [-O-(CH2)4-]n++H2O→[-O-(CH2)4-]nH+H+

4. Purification of Polytetrahydrofuran (PTHF)

The crude polytetrahydrofuran product is purified to remove any unreacted monomer, catalyst residues, and other impurities.

- Neutralization: The reaction mixture is neutralized to remove any residual acid catalyst. This can be done using a base, such as sodium hydroxide (NaOH).

- Washing: The neutralized mixture is washed with water to remove soluble impurities.

- Distillation: The PTHF is distilled under reduced pressure to remove any low molecular weight fractions and remaining volatile impurities.

5. Drying and Packaging

The purified polytetrahydrofuran is dried to remove any residual moisture and then packaged for storage and transportation.

- Drying: The PTHF is dried under vacuum or in a drying oven to achieve the desired moisture content.

- Packaging: The dried PTHF is packaged in airtight containers to prevent contamination and moisture absorption during storage and transportation.

The production of polytetrahydrofuran (PTHF) involves the preparation and purification of tetrahydrofuran (THF), followed by cationic ring-opening polymerization, purification of the polymer, and finally, drying and packaging. Each step in the process is critical to ensuring the quality and performance of the final PTHF product, making it suitable for various industrial applications such as spandex fibers, polyurethane elastomers, and thermoplastic polyurethanes.

REQUEST A QUOTE FOR MORE DETAILS

PTMEG: Storage and Environmental Disposal

Storage

Polytetrahydrofuran (PTHF), also known as polytetramethylene ether glycol (PTMEG), requires careful handling and storage to maintain its quality and ensure safety. Below are the guidelines for the proper storage of PTMEG:

Storage Conditions: PTMEG should be stored in a cool, dry place away from direct sunlight and sources of heat. The recommended storage temperature is typically between 10°C and 25°C (50°F to 77°F). Higher temperatures can lead to degradation of the polymer.

Containers: PTMEG should be stored in tightly sealed, moisture-proof containers to prevent contamination and moisture absorption. Common storage containers include steel drums, polyethylene-lined drums, and airtight plastic containers.

Handling Precautions: When handling PTMEG, it is essential to use appropriate personal protective equipment (PPE), including gloves, goggles, and protective clothing, to avoid skin and eye contact. Ensure that the storage area is well-ventilated to prevent the accumulation of vapors.

Labeling: All containers should be clearly labeled with the product name, hazard symbols, and safety information to ensure proper identification and safe handling.

Shelf Life: PTMEG has a shelf life of about one to two years if stored under recommended conditions. Regular inspections should be conducted to check for signs of degradation or contamination.

Environmental Disposal

Disposal of polytetrahydrofuran (PTHF) must be conducted in a manner that minimizes environmental impact and complies with local regulations. Here are the guidelines for the safe and responsible disposal of PTMEG:

Waste Classification: PTMEG waste should be classified according to local environmental regulations. It is typically considered non-hazardous, but specific classifications can vary based on local laws and the presence of any additives or contaminants.

Recycling and Reuse: Whenever possible, PTMEG waste should be recycled or reused. Industrial facilities may have systems in place to collect and reprocess waste PTMEG into new products, reducing the need for virgin materials and minimizing waste.

Incineration: Incineration is an acceptable method for disposing of PTMEG waste. It should be conducted in a controlled environment at a licensed waste treatment facility equipped with proper air pollution control systems to prevent the release of harmful emissions.

Landfill Disposal: Disposal in a landfill should be a last resort and must comply with local regulations. Ensure that the landfill is approved for industrial waste and that PTMEG is contained to prevent leaching into soil and groundwater.

Environmental Impact: PTMEG is generally considered to have a low environmental impact when disposed of properly. However, improper disposal can lead to soil and water contamination. Always follow best practices and local regulations to minimize environmental risks.

Regulatory Compliance: It is crucial to comply with all relevant local, state, and federal regulations regarding the disposal of PTMEG. This includes obtaining any necessary permits and following guidelines for waste management.

Advantages of the Chinese PTMEG Market

According to relevant data from the Future Market Insights website, the demand for polytetrahydrofuran (PTHF) has seen a significant increase from 2019 to 2023, primarily driven by its versatile applications across various sectors. This demand has resulted in a compound annual growth rate (CAGR) of 5.4% during this period. Looking ahead, the market is forecasted to experience a robust CAGR of 7.4% from 2024 to 2034.

Market Growth and Drivers

China’s Expanding Market: China’s polytetrahydrofuran market is expanding rapidly due to government programs supporting innovation and technical developments. These initiatives are bolstering the country’s manufacturing capabilities and fostering advancements in PTMEG production technologies. The strong demand for PTMEG in China is largely driven by the burgeoning automobile and construction industries, which require durable and flexible materials.

Environmental Sustainability: In line with global trends, Chinese producers of polytetrahydrofuran are increasingly investing in environmentally friendly production methods. This shift is influenced by stringent environmental legislation and a growing emphasis on sustainability. These efforts are aimed at reducing the environmental impact of PTMEG manufacturing and ensuring compliance with international standards.

Healthcare Applications: The adoption of polytetrahydrofuran in the Chinese healthcare industry is expanding, particularly for the production of medical devices. This highlights the broad range of uses for PTMEG beyond traditional industries, demonstrating its versatility and growing importance in medical applications.

Market Projections

The polytetrahydrofuran market is forecasted to grow significantly, with a projected market value of US$ 6,215.32 million by 2024. From 2024 to 2034, the sales of polytetrahydrofuran are expected to expand at a moderate CAGR of 6.0%, reaching an estimated valuation of US$ 11,130.69 million by 2034. This steady growth is driven by the increasing demand from various end-use industries.

Key Industry Trends

Polyurethane Elastomers and Coatings: The growing use of PTMEG in polyurethane elastomers, coatings, and adhesives is a major driver of market growth. These materials are essential in automotive, construction, and textile industries due to their flexibility, durability, and resistance to wear and tear.

Research and Development: Increased spending on research and development is crucial for creating novel PTMEG products. Innovations in production techniques and applications are expected to drive market growth and open new opportunities for manufacturers.

Challenges and Opportunities

Sustainable Manufacturing: Polytetrahydrofuran manufacturers need to explore new opportunities as the emphasis on environmentally friendly and sustainable manufacturing techniques intensifies. The adoption of green technologies and sustainable practices will be crucial for long-term market success.

Raw Material Fluctuations: The potential for the polytetrahydrofuran market to evolve is constrained by price fluctuations and difficulties in obtaining raw materials. Manufacturers must navigate these challenges by securing stable supply chains and managing costs effectively.

Conclusion

The global polytetrahydrofuran (PTHF) market is poised for significant growth, driven by expanding applications in various industries and increased emphasis on sustainability. China’s role in this market is particularly notable due to government support, rising demand in key sectors, and advancements in environmentally friendly production methods. As the market continues to evolve, manufacturers will need to innovate and adapt to sustain growth and meet the increasing demand for PTMEG.

Our Team

FAQs of PTMEG

Polytetramethylene ether glycol (PTMEG), also known as polytetramethylene ether glycol (PTMEG), is a versatile polymer commonly used in the production of spandex fibers, polyurethane elastomers, and various industrial applications. It is valued for its elasticity, durability, and chemical stability.

Polytetrahydrofuran is primarily used in:

- Spandex Fibers: Provides elasticity and durability in textiles.

- Polyurethane Elastomers: Used in flexible foams, coatings, adhesives, and sealants.

- Thermoplastic Polyurethanes (TPU): Applied in footwear, medical devices, and electronics.

- Industrial Applications: Serves as a lubricant, hydraulic fluid, and additive in various formulations.

PTHF should be stored in a cool, dry place away from direct sunlight and heat sources. It should be kept in tightly sealed, moisture-proof containers to prevent contamination and moisture absorption. Ideal storage temperatures range from 10°C to 25°C (50°F to 77°F).

Polytetrahydrofuran should be disposed of in compliance with local regulations. Preferred disposal methods include recycling and reuse, incineration at licensed facilities, and landfill disposal as a last resort. Proper disposal minimizes environmental impact and prevents contamination.

When stored under recommended conditions, PTMEG has a shelf life of approximately one to two years. Regular inspections should be conducted to check for signs of degradation or contamination.

Polytetrahydrofuran offers several benefits in manufacturing:

- Elasticity: Enhances the flexibility and stretchability of products.

- Durability: Provides long-lasting performance and resistance to wear.

- Chemical Stability: Ensures resistance to various chemicals and solvents.

- Versatility: Suitable for a wide range of applications, from textiles to industrial uses.

Absolutely. We offer 100g-200g samples, with the client only covering shipping costs.

Standard lead times are approximately 2-4 weeks, varying based on order size and destination.

Our standard payment terms include a 30% advance and the balance against delivery, but terms can be negotiated for long-term partnerships.

Yes, we offer comprehensive after-sales support, addressing any post-purchase queries or concerns.

As a supplier, in order to provide you with an accurate quote for your product, please inform us of the quantity you require, the required purity specifications, any specific packaging needs, your shipping location, and whether your application requires any customization requirements or certifications.