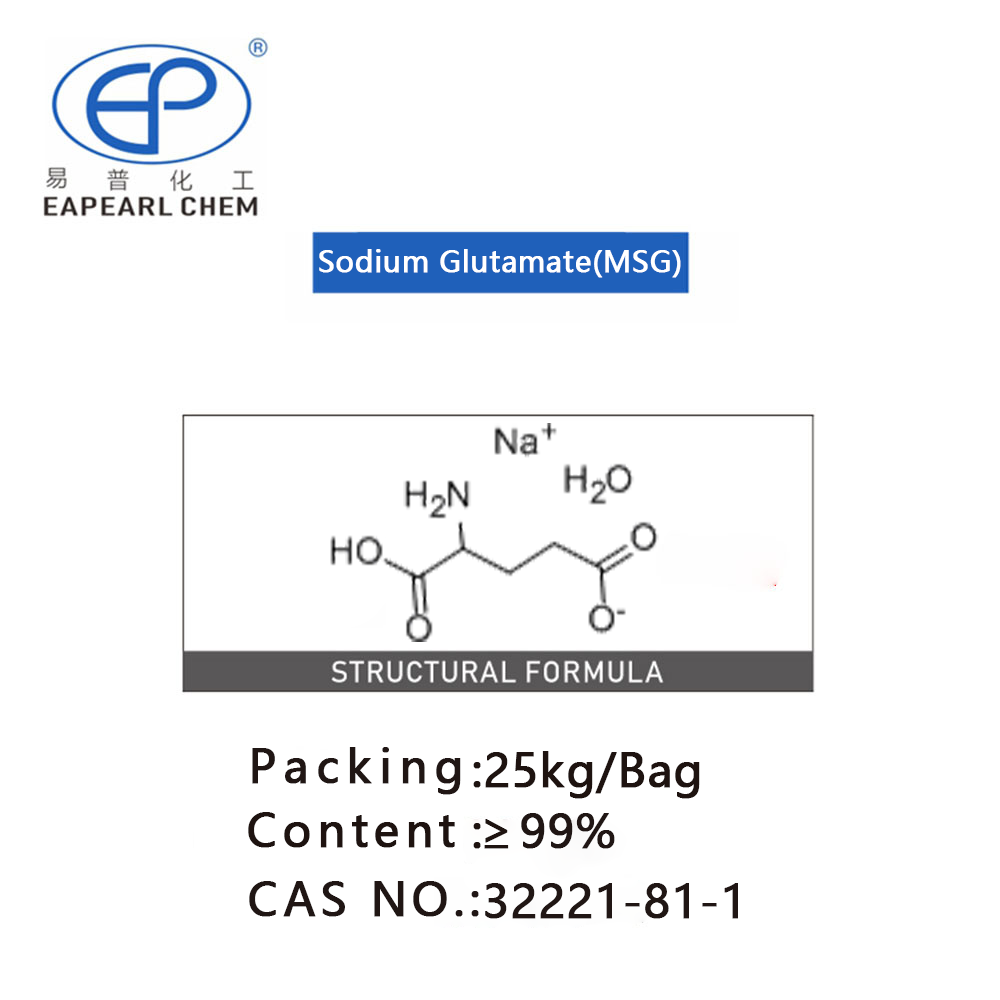

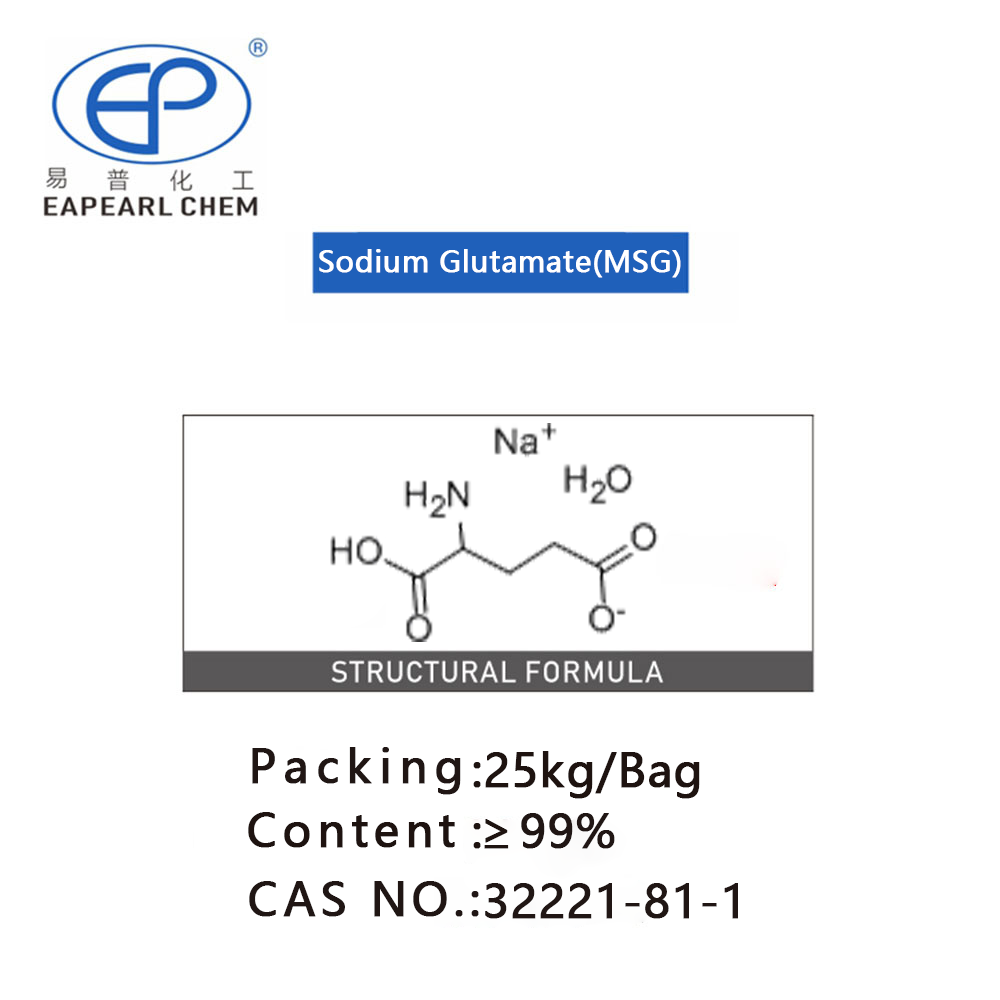

Sodium Glutamate(MSG)

Optimize Your Industry with Eapearl's Pure Sodium Glutamate(MSG)

Empower Your Production with Our Superior Chemical Solutions — Precision,

Purity, and Performance Delivered Globally

What Sodium Glutamate(MSG) Is

Introduction: Sodium Glutamate(MSG) is a white prismatic crystals or crystalline powder, odorless, with a unique meaty flavor, easily soluble in water. It’s an organic compound, and the sodium salt of glutamic acid. The main component of MSG, a commonly used seasoning in daily life, is sodium glutamate. Widely used in households, catering industry, and food processing industry. It is also commonly used as medical and biochemical reagents.

Synonyms: Sodium 5-oxido-5-oxonorvaline; Monosodium glutamate with other flavour-enhancers; DL-monosodium glutamate; sodium glutamate(1-); α-Amiopetandioic acid monosodium salt; sodium acid l-glutamate; Monosodium glutamate; Glutamic acid, monosodium salt, DL-

Chemical Properties: Stable to light and heat, does not absorb moisture. It has a molar mass of 169.11109 g/mol and a 1.635 g/cm³ density. In an acidic environment, sodium glutamate will produce glutamic acid or glutamate hydrochloride; in an alkaline environment, sodium glutamate will react chemically to produce a substance called disodium glutamate.

Reactivity and Uses: Sodium glutamate is the most widely used umami agent at home and abroad. When coexisting with salt, it can enhance its taste-presenting effect. Our country stipulates that it can be used in appropriate amounts in various types of food according to production needs.

Sodium Glutamate(MSG) Packaging Information

Sodium Glutamate(MSG) Packaging | Capacity | 20GP | 40GP |

Bag | 25kgs/bag | total 800 bags, Net 20 Tons | total 1040 bags, Net26 Tons |

Ton Bag | 1 tons/bag | total 20 Ton bags, Net 20 Tons | total 24-26 Ton bags, Net 24-26 Tons |

The Applications of Sodium Glutamate(MSG)

Manufacturing and Industrial Applications

- Organic synthesis intermediates:It can be used as an organic synthesis intermediate in industry, such as in various fields such as additives, permeable membranes, silk protein modification, leather additives, biomedical materials, modified regenerated collagen fibers, etc.

Production Technology of Sodium Glutamate(MSG)

1. Raw Material Preparation

A. Source Materials:

- Carbohydrates: Common sources include starch, molasses, or sugar cane.

- Nitrogen Source: Ammonium salts, urea, or other nitrogenous compounds.

2. Fermentation

A. Microorganisms:

- Select strains of Corynebacterium glutamicum or Brevibacterium flavum are used to produce glutamic acid through fermentation.

B. Fermentation Conditions:

- Temperature: Typically maintained between 30-35°C.

- pH: Controlled at around 7.0 using ammonia or other pH regulators.

- Aeration: Adequate oxygen supply is essential for optimal microbial growth and glutamic acid production.

- Duration: The fermentation process generally takes 2-3 days.

3. Extraction and Purification

A. Separation of Biomass:

- After fermentation, the microbial cells are separated from the fermentation broth using centrifugation or filtration.

B. Crystallization:

- The glutamic acid in the broth is converted to its sodium salt by neutralizing with sodium hydroxide, resulting in MSG.

C. Purification:

- The MSG is then crystallized out of the solution by adjusting the temperature and pH. The crystals are separated, washed, and dried.

4. Refining

A. Recrystallization:

- The crude MSG crystals undergo further purification through recrystallization to achieve high purity. This involves dissolving the crude crystals in water, filtering, and recrystallizing the product.

B. Drying:

- The purified MSG crystals are dried to remove any residual moisture.

C. Milling:

- The dried crystals are milled to the desired particle size.

5. Quality Control

A. Testing:

- The final product undergoes rigorous quality control testing to ensure it meets the required standards for purity, composition, and safety.

B. Packaging:

- The MSG is packaged in suitable containers to protect it from moisture and contamination during storage and transportation.

6. Environmental Considerations

A. Waste Management:

- Proper treatment and disposal of fermentation by-products and waste materials are crucial to minimize environmental impact.

B. Energy Efficiency:

- Optimizing energy use throughout the production process to reduce costs and environmental footprint.

How can we handle your order?

step 1

We will communicate with you within 24 hours after you send an enquiry.

step 2

If you need sample testing, we will send samples within 5 days,≤50kg, Express delivery recommended, usually called as DDU service; delivery time 5-7 days. Door to door service.

step 3

If you need bulk goods after the sample test is qualified, we will ship the goods to the port and keep the samples within 6 days after the order is confirmed. Sea shipping recommended, usually called as FOB, CFR, or CIF service.delivery time 10-45 days. Port to port service.

step 4

After waiting for you to receive the goods, we will arrange professional staff to pay a return visit within 7 days.

REQUEST A QUOTE FOR MORE DETAILS

Sodium Glutamate(MSG) Technical Data

Name | Sodium Glutamate(MSG) |

Molecular Formula | C5H8NNaO4 |

Molecular Weight | 169.11109 |

CAS | 32221-81-1 |

Density | 1.635 g/mL |

Melting Point | 225 ℃ |

Boling Point | 333.8 ℃ |

Flash Point | 155.7 ℃ |

InChI | InChI=1S/C5H9NO4.Na/c6-3(5(9)10)1-2-4(7)8;/h3H,1-2,6H2,(H,7,8)(H,9,10);/q;+1/p-1 |

InChIKey | LPUQAYUQRXPFSQ-UHFFFAOYSA-M |

Solubility | 10 g/100mL(cold water),71.7 g/100mL(hot water) |

Appearance | White crystalline solid |

Color | White |

Odor | Practically Odorless |

PH | 6.7~7.2 (1.0 g, H2O 10ml) |

Storage Condition | Shield from light and store in a sealed container. |

Stability | Stable. Incompatible with strong oxidizing agents. |

Sensitive | Non-hygroscopic |

Physical and Chemical Properties | White crystalline solid, odorless, with a unique meat flavor. |

Optical Activity | The molecular structure of sodium glutamate contains an asymmetric carbon atom, which is optically active and can rotate the polarized light plane at a certain angle. |

Environment and Health

Environmental Impact

The production of MSG typically involves the fermentation of carbohydrates like sugarcane or corn starch. This process can have several environmental implications:

- Water Consumption: The fermentation process requires significant amounts of water, leading to concerns about water resource depletion.

- Energy Use: Large-scale fermentation and purification processes consume considerable energy, contributing to carbon emissions.

- Waste Generation: The production process generates by-products and waste materials, which need to be managed properly to avoid environmental contamination.

Storage and transportation

- Store in a cool, ventilated warehouse. Keep away from fire and heat sources. Keep container tightly sealed. They should be stored separately from acidic substances, strong oxidants, and flammable substances, and avoid mixed storage. Suitable materials should be available in the storage area to contain spills.

- Operators must undergo special training and strictly abide by operating procedures. It is recommended that operators wear self-priming filter dust masks, chemical safety glasses, anti-toxic substance penetration overalls, and rubber gloves. Avoid dust generation. Avoid contact with acids, strong oxidants, and flammable materials. When handling, load and unload with care to prevent damage to packaging and containers. Equipped with leakage emergency treatment equipment.

Health Implications

- It is generally harmless if inhaled, absorbed or absorbed through the skin. Excessive heating will produce sodium pyroglutamate, which may have certain effects on human health.

- Eye contact: Lift eyelids and rinse with running water or saline. Seek medical attention.

Regulatory Compliance

- MSG is recognized as safe for consumption by numerous health authorities, including the U.S. Food and Drug Administration (FDA) and the World Health Organization (WHO). However, it is regulated to ensure purity and safety for consumers.

Sodium Glutamate(MSG) FAQs

Monosodium glutamate (MSG) is the sodium salt of the common amino acid glutamic acid. Glutamic acid is naturally present in our bodies, and in many foods and food additives.

FDA considers the addition of MSG to foods to be “generally recognized as safe” (GRAS). Although many people identify themselves as sensitive to MSG, in studies with such individuals given MSG or a placebo, scientists have not been able to consistently trigger reactions.

The glutamate in MSG is chemically indistinguishable from glutamate present in food proteins. Our bodies ultimately metabolize both sources of glutamate in the same way. An average adult consumes approximately 13 grams of glutamate each day from the protein in food, while intake of added MSG is estimates at around 0.55 grams per day.

To place a bulk order, contact our sales team via the contact form on our website or call us directly. Our streamlined ordering process ensures a smooth transaction.

Pricing is determined based on order quantity and current market conditions. For a precise quote, please reach out to our sales team.

Yes, we provide discounts on bulk purchases. The discount rate varies depending on the order volume.

We employ rigorous batch testing and quality control processes to guarantee consistent quality in every shipment.

Yes, we offer comprehensive after-sales support, addressing any post-purchase queries or concerns.

Eapearl Chemicals stands out due to our commitment to quality, competitive pricing, reliable supply chain, global reach, and customer-centric approach, ensuring you get the best value and service.

We adhere to strict safety protocols, including regular quality checks, providing clear handling instructions, and ensuring compliance with all regulatory standards to ensure the safety of our Sodium Glutamate(MSG)