Sodium Hydroxide

Discover Sodium Hydroxide for Reliable and Efficient Industrial Applications

Ensuring Your Production Runs Smoothly with Top-Quality NaOH

Introduction:Sodium Hydroxide (NaOH), commonly known as lye or caustic soda, is a highly versatile and widely used chemical compound. It appears as a white, odorless, crystalline solid at room temperature and is highly soluble in water, forming a strongly alkaline solution. Sodium Hydroxide is a fundamental component in numerous industrial processes due to its reactive nature and effectiveness as a strong base.

Nature and Characteristics:The scientific sodium hydroxide is NaOH, commonly known as fire alkali , harsh sodium,Caustic soda,soda lye,white caustic,sodium hydrate,flake caustic. It is a strong alkali with strong corrosion. It is white crystal at normal temperature, which is easily soluble in water. The absorption of water vapor in the air has a moisture, and the carbonized carbonized carbonized changes. It is divided into two types: liquid alkali and solid alkali. Among them, the solid alkali is white, with pieces, chip, stick -like, and granular; liquid alkali is a colorless transparent liquid.

Table of Contents

Packing Instruction

Sodium Hydroxide Packaging | Capacity | 20GP | 40GP |

| Bag | 25kgs/bag | total 800 bags, Net 20 Tons | total 1040 bags, Net26 Tons |

| Ton Bag | 1 tons/bag | total 20 Ton bags, Net 20 Tons | total 24-26 Ton bags, Net 24-26 Tons |

REQUEST A QUOTE FOR MORE DETAILS

How Sodium Hydroxide is Used in Various Industries

Sodium Hydroxide (NaOH) is a critical component in numerous industrial applications due to its versatility and effectiveness as a strong base. Below is a detailed overview of how Sodium Hydroxide is used across different industries:

1.Cosmetics Industry

- Soap and Detergent Manufacturing: Sodium Hydroxide is used to saponify fats and oils, creating soaps. It ensures the correct texture, hardness, and cleaning properties in both solid and liquid soaps.

- pH Regulation: NaOH adjusts the pH levels in various cosmetic products, ensuring they are safe for skin application.

2.Food Processing

- Food Preparation:Used in the peeling of fruits and vegetables, removing skins without damaging the produce.

- Cocoa and Chocolate Processing: Enhances flavor and color during the cocoa processing stages.

- Pretzel and Bagel Production:Creates the characteristic crust on pretzels and bagels by dipping them in a NaOH solution before baking.

3.Textile Industry

- Mercerization of Cotton: Sodium Hydroxide is used to treat cotton fibers, increasing their strength, luster, and dye affinity, resulting in higher-quality fabrics.

- Dyeing and Finishing:Helps in the dyeing process by preparing fibers to better absorb dyes and in finishing processes to achieve the desired fabric properties.

4.Chemical Manufacturing

- Production of Chemicals: Used in the manufacturing of various chemicals, including solvents, plastics, and pharmaceuticals.

- Catalyst in Reactions: Acts as a catalyst in numerous chemical reactions, improving reaction efficiency and yield.

5.Rubber Industry

- Synthetic Rubber Production: NaOH is involved in the polymerization processes, aiding in the production of synthetic rubber, which is used in tires and various other rubber products.

- Latex Processing: Used to stabilize latex rubber, ensuring consistency and quality in the final product.

6.Resins and Polyurethanes

- Epoxy Resin Production: Sodium Hydroxide is used in the production of epichlorohydrin, a key precursor for epoxy resins.

- Polyurethane Manufacturing: Plays a role in the production of polyurethane foams, elastomers, and coatings, widely used in construction, automotive, and furniture industries.

7.Fragrances

- Fragrance Synthesis:Sodium Hydroxide is used in various chemical reactions to produce fragrance ingredients, ensuring purity and quality.

8.Adhesives

- Adhesive Formulation: NaOH is used in the production of various adhesives, providing the necessary properties for strong bonding in industrial and consumer products.

9.Water Treatment

- pH Adjustment:Used to neutralize acidic water, making it safe for consumption and use.

- Water Softening: Helps in removing hardness from water, preventing scale buildup in pipes and appliances.

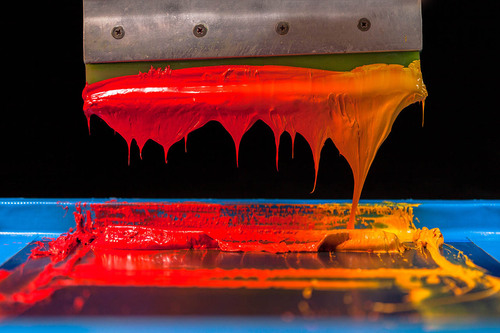

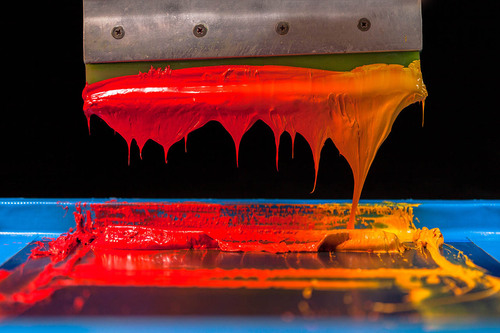

10.Inks and Coatings

- Ink Formulation: Used to adjust the pH and as a cleaning agent for equipment in ink production.

- Paints and Coatings: NaOH helps in the production of acrylic coatings, ensuring proper adhesion and durability.

REQUEST A QUOTE FOR MORE DETAILS

The Dangers and Safety Precautions of Sodium Hydroxide

Sodium Hydroxide (NaOH) is a powerful and highly reactive chemical. While it has numerous beneficial applications across various industries, it also poses significant dangers if not handled correctly. Understanding these dangers and implementing appropriate safety precautions is crucial to ensure safe usage.

Dangers of Sodium Hydroxide

1.Caustic Burns

- Sodium Hydroxide is highly corrosive and can cause severe burns upon contact with skin or eyes. These burns can result in deep tissue damage.

- Contact with eyes can cause serious eye damage, including blindness.

2.Respiratory Hazards

- Inhalation of Sodium Hydroxide dust or mist can irritate the respiratory tract, leading to coughing, shortness of breath, and in severe cases, pulmonary edema (fluid accumulation in the lungs).

3.Chemical Reactions

- Sodium Hydroxide reacts exothermically with water, releasing a large amount of heat that can cause splattering and potential burns.

- It reacts vigorously with acids, generating heat and possibly leading to violent reactions.

- Reacts with certain metals, such as aluminum, to produce hydrogen gas, which is highly flammable and can form explosive mixtures with air.

4.Ingestion

- Ingesting Sodium Hydroxide can cause severe burns to the mouth, throat, and stomach, potentially leading to serious injury or death.

Safety Precautions for Handling Sodium Hydroxide

1.Personal Protective Equipment (PPE)

- Gloves: Wear chemical-resistant gloves, such as those made of neoprene or rubber, to prevent skin contact.

- Eye Protection: Use safety goggles or face shields to protect eyes from splashes.

- Clothing:Wear long-sleeved lab coats, aprons, or chemical-resistant clothing to protect skin from exposure.

- Respiratory Protection: Use appropriate respirators if there is a risk of inhaling dust or mist.

2.Handling and Storage

- Ventilation: Ensure good ventilation in areas where Sodium Hydroxide is used to prevent the accumulation of dust or fumes.

- Storage: Store Sodium Hydroxide in a cool, dry place, away from incompatible substances such as acids and metals. Use containers made of materials resistant to caustic substances, like polyethylene or stainless steel.

- Labeling: Clearly label all containers with appropriate hazard warnings.

3.Emergency Procedures

- Eye Contact: In case of eye contact, rinse immediately with plenty of water for at least 15 minutes and seek medical attention.

- Skin Contact: Remove contaminated clothing and wash the affected area with plenty of water. Seek medical attention if irritation persists.

- Inhalation: Move the affected person to fresh air immediately. If breathing difficulties occur, seek medical attention.

- Ingestion: Do not induce vomiting. Rinse mouth with water and seek immediate medical attention.

4.Spill Response

- Containment: Contain spills using appropriate barriers to prevent spreading.

- Neutralization: Use a neutralizing agent, such as dilute acetic acid or citric acid, to neutralize the spill.

- Cleanup: Clean up the spill with non-reactive absorbent materials, such as vermiculite or sand, and dispose of waste according to local regulations.

5.Training and Awareness

- Ensure that all personnel handling Sodium Hydroxide are trained in its hazards and the proper safety precautions.

- Display safety data sheets (SDS) and emergency contact information in accessible locations.

By understanding the dangers associated with Sodium Hydroxide and implementing these safety precautions, industries can minimize risks and ensure the safe handling of this essential chemical.

Storage Method of Sodium Hydroxide

Proper storage of Sodium Hydroxide (NaOH) is crucial to ensure safety and maintain its quality. Here are the recommended practices for storing Sodium Hydroxide:

- Container Material

- Chemical Resistance: Use containers made from materials that are resistant to corrosion and chemical reactions with Sodium Hydroxide. Suitable materials include high-density polyethylene (HDPE), polypropylene (PP), or stainless steel.

- Sealed Containers: Ensure that the containers are tightly sealed to prevent exposure to air and moisture, which can cause the NaOH to absorb water and carbon dioxide from the atmosphere, leading to the formation of sodium carbonate (Na2CO3).

- Labeling

- Proper Labeling: Clearly label containers with the content name “Sodium Hydroxide,” concentration (if in solution), hazard symbols, and appropriate safety warnings.

- Safety Data Sheet (SDS): Keep an SDS accessible near the storage area for reference in case of an emergency.

- Environmental Conditions

- Dry Area: Store Sodium Hydroxide in a cool, dry place to minimize the risk of moisture absorption.

- Temperature Control: Maintain a stable temperature, avoiding extreme temperatures that could affect the integrity of the storage container and the stability of the chemical.

- Ventilation:Ensure the storage area is well-ventilated to prevent the accumulation of any fumes that might be released.

- Segregation

- Away from Incompatibles: Store Sodium Hydroxide away from incompatible substances such as acids, organic materials, metals (e.g., aluminum, zinc), and flammable liquids. This prevents hazardous reactions that could result in fires, explosions, or the release of toxic gases.

- Separate Storage Area: Use a dedicated storage area for Sodium Hydroxide to avoid cross-contamination with other chemicals.

- Handling Precautions

- Personal Protective Equipment (PPE): Ensure that personnel handling Sodium Hydroxide wear appropriate PPE, including chemical-resistant gloves, safety goggles, face shields, and protective clothing.

- Spill Containment: Equip the storage area with spill containment measures such as secondary containment trays or bunding to contain any accidental spills or leaks.

- Emergency Preparedness

- Emergency Equipment: Keep emergency equipment such as eyewash stations, safety showers, and spill kits readily available near the storage area.

- First Aid Kits: Have first aid kits accessible in case of exposure or accidents.

- Emergency Procedures: Display clear emergency procedures and contact information for quick reference.

- Inspection and Maintenance

- Regular Inspections: Conduct regular inspections of the storage area and containers to check for signs of leaks, corrosion, or damage.

- Maintenance: Promptly repair or replace any damaged containers to prevent potential hazards.

Summary

By following these storage guidelines, you can ensure the safe and effective storage of Sodium Hydroxide, protecting both personnel and the environment from potential hazards. Proper storage practices also help maintain the chemical’s quality and extend its shelf life, ensuring reliable performance in various industrial applications.

REQUEST A QUOTE FOR MORE DETAILS

Preparation of Sodium Hydroxide

Sodium Hydroxide (NaOH), also known as caustic soda, is commonly prepared through several industrial methods. The most prevalent and efficient method is the Chloralkali Process. This method includes the electrolytic decomposition of sodium chloride (NaCl) in brine to produce sodium hydroxide, chlorine, and hydrogen. Below is an overview of the various methods used for the preparation of Sodium Hydroxide.

Chloralkali Process

1.Electrolysis of Brine

The Chloralkali Process involves the electrolysis of brine (a concentrated solution of sodium chloride). This process can be carried out using different types of electrolytic cells:

- Mercury Cell Process

- Diaphragm Cell Process

- Membrane Cell Process

Among these, the Membrane Cell Process is the most environmentally friendly and widely used due to its efficiency and lower environmental impact.

2.Steps in the Membrane Cell Process

1.)Preparation of Brine:

- Brine is prepared by dissolving purified sodium chloride in water. The brine solution is then purified to remove impurities such as calcium, magnesium, and sulfates which can affect the efficiency of the electrolysis process.

2.)Electrolysis:

- The purified brine is passed into the membrane electrolytic cell, which consists of an anode and a cathode separated by an ion-exchange membrane.

- At the anode, chloride ions (Cl-) are oxidized to produce chlorine gas (Cl2).

- At the cathode, water molecules are reduced to produce hydrogen gas (H2) and hydroxide ions (OH-).

- The hydroxide ions (OH-) combine with sodium ions (Na+) from the brine to form sodium hydroxide (NaOH).

3.)Collection of Products:

- Chlorine gas is collected from the anode compartment.

- Hydrogen gas is collected from the cathode compartment.

- Sodium hydroxide is collected as an aqueous solution from the cathode compartment.

Chemical Reactions

- Anode Reaction: 2Cl−→Cl2(g)+2e−

- Cathode Reaction: 2H2O+2e−→H2(g)+2OH−

- Overall Cell Reaction: 2NaCl+2H2O→2NaOH+Cl2(g)+H2(g)

Chemical Process

Another method for the preparation of sodium hydroxide involves the chemical reaction between calcium hydroxide (slaked lime) and sodium carbonate (soda ash). This process is known as the Lime-Soda Process.

Steps in the Lime-Soda Process

1.Mixing:

- Calcium hydroxide (Ca(OH)2) is mixed with sodium carbonate (Na2CO3) in water.

2.Reaction:

- The mixture undergoes a chemical reaction to produce sodium hydroxide (NaOH) and calcium carbonate (CaCO3).

Chemical Reaction

Ca(OH)2+Na2CO3→2NaOH+CaCO

3.Separation:

- The resulting sodium hydroxide solution is separated from the insoluble calcium carbonate precipitate by filtration or sedimentation.

4.Purification:

- The sodium hydroxide solution is then concentrated and purified to achieve the desired concentration and purity.

Summary of Advantages and Disadvantages

Chloralkali Process

Advantages:

- High purity of sodium hydroxide.

- Co-production of valuable chlorine and hydrogen gases.

- Efficient and scalable for large-scale production.

Disadvantages:

- Requires significant energy input for electrolysis.

- Handling and disposal of chlorine gas can pose environmental and safety challenges.

Lime-Soda Process

Advantages:

- Simpler chemical process with lower energy requirements.

- Utilizes readily available raw materials.

Disadvantages:

- Produces a lower purity product compared to the Chloralkali Process.

- Generates a large amount of calcium carbonate waste, which requires disposal.

By selecting the appropriate method based on the specific requirements and available resources, industries can efficiently produce high-quality sodium hydroxide to meet their needs.

REQUEST A QUOTE FOR MORE DETAILS

Advantages of Sodium Hydroxide in the Chinese Market

1.High Domestic Production Capacity

China has a significant production capacity for Sodium Hydroxide, ensuring a steady and reliable supply for various industries. The robust infrastructure and investment in chemical manufacturing allow China to meet both domestic and international demand efficiently.

2.Cost Efficiency

- The production cost of Sodium Hydroxide in China is relatively lower due to the availability of raw materials and economies of scale. This cost advantage makes Chinese Sodium Hydroxide highly competitive in the global market.

3.Technological Advancements

- Chinese manufacturers have adopted advanced production technologies, such as the Membrane Cell Process, which enhances the quality and purity of Sodium Hydroxide. These technological advancements contribute to the production of high-quality products that meet international standards.

4.Diverse Industrial Applications

- Sodium Hydroxide is utilized across multiple industries in China, including textiles, paper and pulp, food processing, and water treatment. The versatility of Sodium Hydroxide ensures a consistent demand across various sectors, driving market growth.

5.Environmental Regulations

- Stringent environmental regulations in China have led to the adoption of cleaner and more sustainable production methods for Sodium Hydroxide. Compliance with these regulations ensures that Chinese Sodium Hydroxide is environmentally friendly, appealing to eco-conscious buyers.

6.Strong Export Market

- China is a major exporter of Sodium Hydroxide, supplying it to numerous countries worldwide. The strong export market is supported by competitive pricing, high-quality products, and efficient logistics, making China a preferred supplier in the international market.

7.Strategic Location and Logistics

China’s strategic geographical location and well-developed logistics network facilitate efficient distribution and export of Sodium Hydroxide. The proximity to key markets in Asia and beyond reduces shipping times and costs, enhancing the competitiveness of Chinese Sodium Hydroxide.

8.Government Support

- The Chinese government supports the chemical industry, including sodium hydroxide, through favorable policies and subsidies, enhancing its global competitiveness.

These factors make China a favorable source for high-quality and cost-effective sodium hydroxide, benefiting foreign buyers in the B2B sector.

REQUEST A QUOTE FOR MORE DETAILS

How to Distinguish Between Caustic Soda (Sodium Hydroxide) and Soda Ash (Sodium Carbonate)

Soda ash and caustic soda are known as the “industrial alkalies” and belong to the salt chemical industry, commonly used alkaline substances.

Despite both being alkaline, they have significant differences in properties, uses, and safety。

Definition:

Caustic soda, also known as fire -alkali, its chemical name is sodium hydroxide (NaOH), composed of sodium (Na) and hydroxide (OH) ions, which is a white solid with strong corrosiveness, which is easy to dissolve in water and releases a lot of heat. At room temperature, it appears as white crystals, easily dissolving in water to form an alkaline solution. Sodium Hydroxide is a fundamental chemical raw material, widely used in various industries such as aluminum oxide production, papermaking, dyeing, chemical fibers, water treatment, metal refining, petroleum refining, cotton fabric processing, coal tar purification, food processing, wood processing, and the machinery and chemical industries.

Soda Ash (Sodium Carbonate),composed of sodium (Na), carbon (C), and oxygen (O) ions,commonly known as soda ash or washing soda, is a sodium salt of carbonic acid. It appears as a white, water-soluble salt.It has the generality and thermal stability of salt, which is easily soluble in water, and its aqueous solution is alkaline.

Ingredients:

Caustic Soda:The main component of the Caustic Soda is sodium hydroxide, which is a strong alkaline substance.

Soda Ash:The main ingredients of Soda Ash are sodium carbonate, which is a kind of inorganic salt.

Pureness:

The purity of edible alkali is relatively low, containing a certain impurities; and the purity of the alkali is higher.

Physical Properties:

Caustic Soda: Appears as a white crystalline solid; highly hygroscopic and corrosive.

Soda Ash: Appears as a white powder or granular solid; less corrosive compared to caustic soda.

Chemical Behavior:

Caustic Soda: Strong alkali with a high pH; reacts vigorously with acids and water, releasing heat.

Soda Ash: Moderate alkali; reacts with acids to produce carbon dioxide gas and water.

Safety:

Caustic Soda has strong corrosiveness, and directly contact or error can cause serious damage. It is necessary to strictly observe the obey of strictly. Safety operation regulations.

Soda Ash are harmless to the human body under an appropriate amount, but excessive intake may lead to dysfunction in the body in the body.

Uses:

Caustic Soda is mainly used for industrial production, such as papermaking and chemical industry.

Soda Ash is mainly used for food processing and daily cleaning, such as the production of noodles and cakes.

Different production processes

Caustic Soda:Caustic soda is a midstream product of the chlor-alkali industry chain. Its production method evolved from the causticizing process to the electrolytic process, and finally to the current ion-exchange membrane electrolysis method, which has become the mainstream method in China, accounting for over 99% of production, resulting in relatively uniform production processes.

Soda Ash:The production processes of soda ash are divided into the ammonia-soda process, the combined soda process, and the natural soda process. The ammonia-soda process accounts for about 49%, the combined soda process for 46%, and the natural soda process for about 5%.

Product Classification Differences

Soda ash is classified into light and dense types, both in solid form, distinguished by density.

Caustic soda comes in liquid and solid forms:

Liquid Caustic Soda: Based on sodium hydroxide content, available in concentrations of 30%, 32%, 42%, 45%, and 50%, with 32% and 50% being the mainstream specifications.

Solid Caustic Soda: Mainly 99% sodium hydroxide flake caustic soda.

In China, liquid caustic soda production accounts for over 80% of the total, while 99% flake caustic soda accounts for about 14%.

Understanding these differences ensures their safe and effective application in various industrial processes.

Sodium Hydroxide Technical

| Name | Sodium hydroxide |

| Synonyms | Caustic soda,soda lye,white caustic,sodium hydrate,flake caustic |

| CAS NO. | 1310-73-2 |

| Molecular Formula | NaOH |

| Molar Mass | 40.00 g/mol |

| EINECS NO. | 215-185-5 |

| Melting Point | 318°C (604°F) |

| Boiling Point | 1,388°C (2,530°F) |

| Density | 2.13 g/cm³ at 20°C (68°F) |

| Vapor Density | <1(vs air) |

| Vapor Presure | 1 mm Hg ( 745 °C) |

| Refractive Index | 1,473-1,475 |

| Flash Point | 176-178°C |

| Appearance | White, odorless solid (available in flakes, pellets, or granules) |

| proportion | 2.13 |

| Odor | Tasteless |

| pH | Highly alkaline (approximately 14 in a 1M aqueous solution) |

| Solubility | Highly soluble in water, with exothermic dissolution |

| Sensitive | Air Sensitive & Hygroscopic |

| Decomposition | 176-178 ºC |

| Merck | 148627 |

| Reactivity | Reacts vigorously with acids, water (producing heat), and certain organic compounds |

REQUEST A QUOTE FOR MORE DETAILS

FAQs of Sodium Hydroxide

Sodium hydroxide, also known as fire -alkali,caustic soda, its composed of sodium (Na) and hydroxide (OH) ions, which is a white solid with strong corrosiveness, which is easy to dissolve in water and releases a lot of heat. At room temperature, it appears as white crystals, easily dissolving in water to form an alkaline solution. Sodium Hydroxide is a fundamental chemical raw material, widely used in various industries such as aluminum oxide production, papermaking, dyeing, chemical fibers, water treatment, metal refining, petroleum refining, cotton fabric processing, coal tar purification, food processing, wood processing, and the machinery and chemical industries.

Pricing is determined based on order quantity and current market conditions. For a precise quote, please reach out to our sales team.

Yes, we provide discounts on bulk purchases. The discount rate varies depending on the order volume.

Our minimum order quantity is 1 ton, catering to both large and small-scale needs.

We employ rigorous batch testing and quality control processes to guarantee consistent quality in every shipment.

Standard lead times are approximately 2-4 weeks, varying based on order size and destination.

Absolutely. We offer 100g-200g samples, with the client only covering shipping costs.

Our standard payment terms include a 30% advance and the balance against delivery, but terms can be negotiated for long-term partnerships.

We manage all aspects of international shipping and customs clearance, ensuring compliance with export and import regulations.

Yes, we offer comprehensive after-sales support, addressing any post-purchase queries or concerns.

We adhere to all international trade regulations. If there are specific restrictions applicable to your industry, we’ll inform you during our initial discussions.

How can we handle your order?

step 1

We will communicate with you within 24 hours after you send an enquiry.

step 2

If you need sample testing, we will send samples within 5 days,≤50kg, Express delivery recommended, usually called as DDU service; delivery time 5-7 days. Door to door service.

step 3

If you need bulk goods after the sample test is qualified, we will ship the goods to the port and keep the samples within 6 days after the order is confirmed. Sea shipping recommended, usually called as FOB, CFR, or CIF service.delivery time 10-45 days. Port to port service.

step 4

After waiting for you to receive the goods, we will arrange professional staff to pay a return visit within 7 days.