Sodium Nitrate

Optimize Your Industry with Eapearl's Pure Sodium Nitrate

Empower Your Production with Our Superior Chemical Solutions — Precision, Purity, and Performance Delivered Globally

What Sodium Nitrate Is

Sodium nitrate is a white crystalline solid, highly soluble in water, and non-hygroscopic, meaning it does not absorb moisture from the air. Its chemical stability under normal conditions makes it a versatile compound suitable for various applications. Its solubility increases with temperature, allowing for easy dissolution in industrial processes requiring aqueous solutions.

Synonyms:

E251 , niter , nitratine , Soda niter , cubicniter, nitrateofsoda , CHILE SALPETER , Sodium nitrate , Natriumnitrat

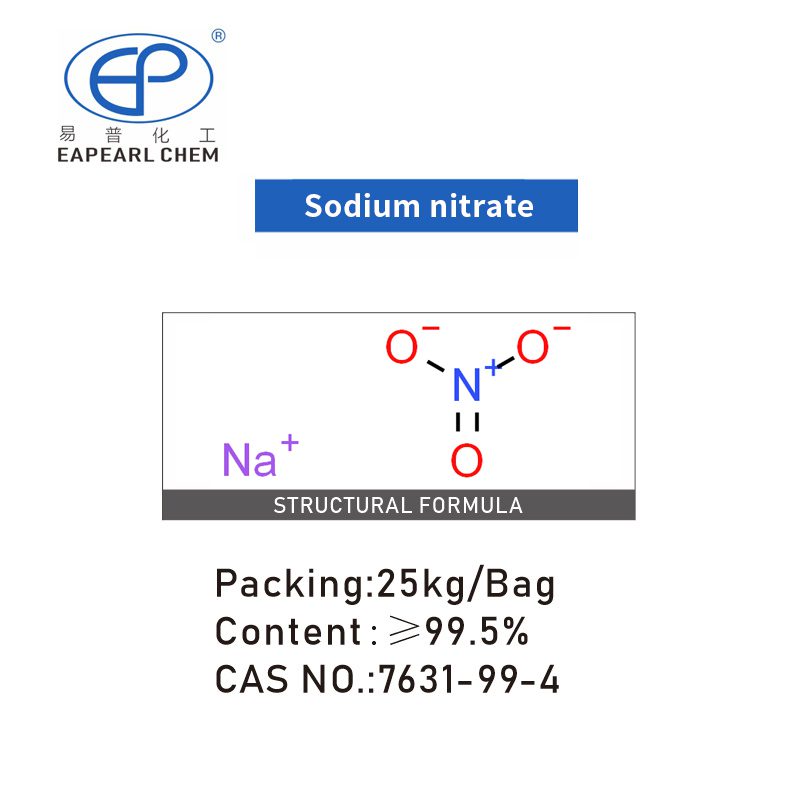

Chemical Properties

Sodium nitrate is an ionic compound composed of sodium cations (Na⁺) and nitrate anions (NO₃⁻). It has a molar mass of 84.994 g/mol and a 2.257 g/cm³ density. The compound decomposes upon heating, releasing oxygen and leaving behind sodium nitrite, which can further decompose to sodium oxide and nitrogen dioxide if the temperature is sufficiently high.

Reactivity and Uses

Sodium nitrate is a potent oxidizing agent, which is why it finds use in the manufacture of explosives where rapid oxidation is necessary. Its oxidizing power also makes it effective in glass and ceramics production to enhance the processing of materials and improve product characteristics.

Sodium Nitrate Packaging Information

| Sodium Nitrate Packaging | Capacity | 20GP | 40GP |

| Bag | 25kgs/bag | total 800 bags, Net 20 Tons | total 1040 bags, Net26 Tons |

| Ton Bag | 1 tons/bag | total 20 Ton bags, Net 20 Tons | total 24-26 Ton bags, Net 24-26 Tons |

The Applications of Sodium Nitrate

Agriculture and Fertilizers

- Nutrient Source: Sodium nitrate is a valuable source of nitrogen, an essential nutrient for plant growth. It is used in fertilizers to enhance soil fertility and promote healthy growth in crops.

- Soil Conditioner: It improves soil properties, aiding in better root development and water retention.

Food Preservation and Processing

- Meat Curing: Sodium nitrate is used in curing meats like bacon, ham, and sausages. It preserves the color and prevents the growth of bacteria, particularly Clostridium botulinum, the bacteria responsible for botulism.

- Food Additive: It is a preservative in various food products, extending their shelf life and maintaining quality.

Manufacturing and Industrial Applications

- Metal Treatment: In metallurgy, it is used for surface treatment of metals, particularly in processes like nitriding.

Pharmaceutical Industry

- Medicinal Uses: Sodium nitrate has applications in the pharmaceutical industry, where it’s used in specific therapeutic formulations, including heart and vascular medicines.

Glass and Pottery Production

- Glass Manufacturing: It is used in the glass-making process to enhance the thermal properties of glass and to reduce melting temperatures, thereby improving energy efficiency.

- Ceramics: In pottery and ceramics, sodium nitrate acts as a flux, helping to fuse other components during firing.

Wastewater Treatment

- Odor Control: In wastewater treatment plants, sodium nitrate is used to control sulfide odors by facilitating the oxidation of sulfides.

- Denitrification Process: It serves as a nutrient source for bacteria involved in the denitrification process, essential for removing nitrogen compounds from wastewater.

Explosives and Pyrotechnics

- Fireworks are a common ingredient in pyrotechnics for producing fireworks, providing the necessary oxygen to have vivid colors and effects.

- Explosives: Due to its oxidizing properties, sodium nitrate is a component in the manufacturing of explosives, where it helps in the rapid release of oxygen, aiding in combustion.

Production Technology of Sodium Nitrate

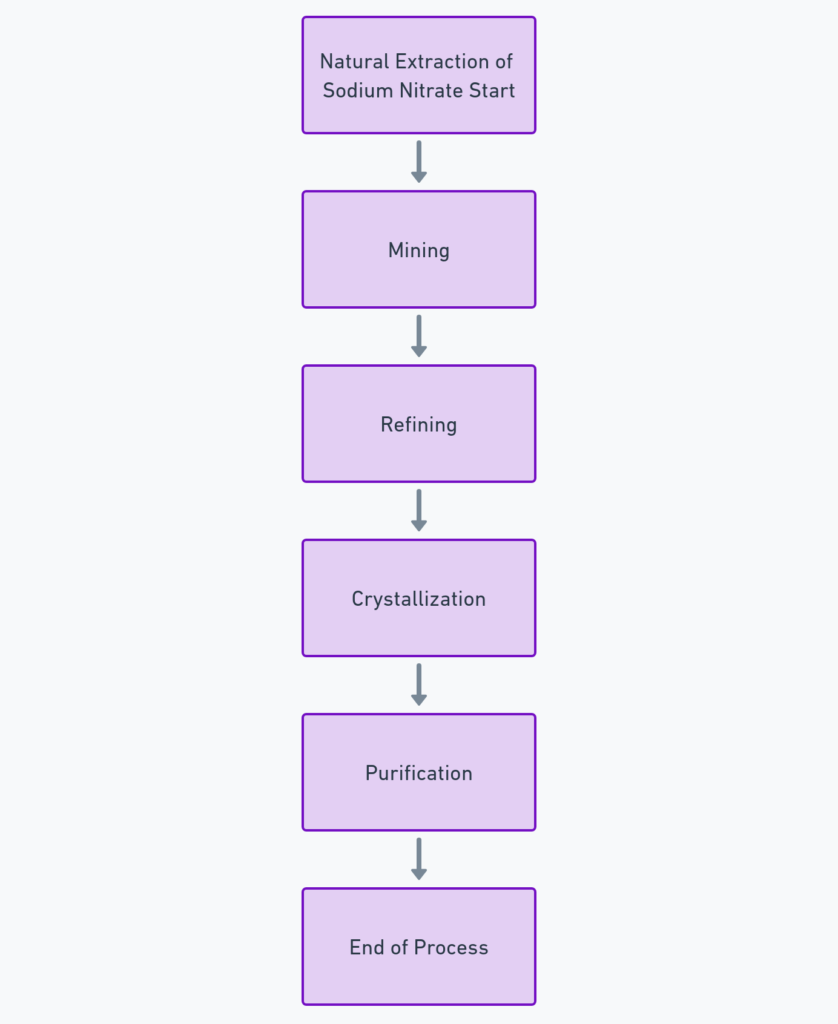

Natural Extraction (Chilean Method)

Historically, sodium nitrate was obtained from natural deposits, primarily found in Chile, hence the name “Chile saltpeter.”

- Mining: Large deposits of sodium nitrate were mined from the nitrate-rich caliche ore found in the Atacama Desert.

- Refining: The mined ore was refined to remove impurities. This involved crushing the caliche and leaching it with water to dissolve the sodium nitrate.

- Crystallization: The solution was then subjected to a crystallization process. As the water evaporated, sodium nitrate crystals formed.

- Purification: The crystals were further purified through washing and recrystallization to achieve the desired purity levels.

Though historically significant, this method has largely been replaced by synthetic production methods due to limited natural reserves and environmental concerns.

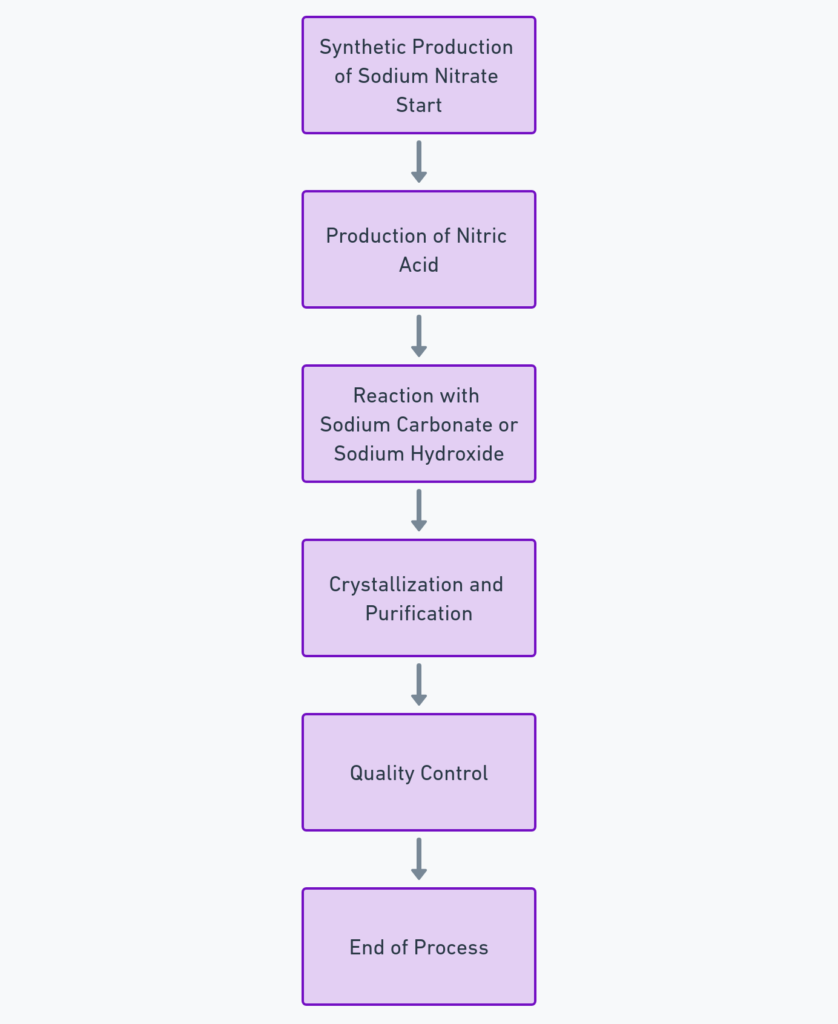

Synthetic Production

The modern production of sodium nitrate is primarily synthetic, involving the reaction of nitric acid with sodium carbonate or sodium hydroxide.

- Step 1: Production of Nitric Acid

- Nitric acid is produced industrially by the Ostwald process.

- Ammonia is oxidized to nitric oxide (NO) using a platinum catalyst at high temperatures.

- The nitric oxide is oxidized to nitrogen dioxide (NO₂), which is then absorbed in water to form nitric acid (HNO₃).

- Step 2: Reaction with Sodium Carbonate or Sodium Hydroxide

- Nitric acid is reacted with sodium carbonate (Na₂CO₃) or sodium hydroxide (NaOH) to produce sodium nitrate.

- The reaction with sodium carbonate is as follows:

- 2HNO3+Na2CO3→2NaNO3+H2O+CO2

- Alternatively, the reaction with sodium hydroxide is:

- HNO3+NaOH→NaNO3+H2O

- Crystallization and Purification

- The resulting solution contains sodium nitrate, which is then crystallized out of the solution.

- Impurities are removed by filtration, and the crystals are dried.

- Further purification may involve recrystallization or additional washing, depending on the required purity level for specific applications.

- Quality Control

- Quality control measures are implemented throughout the manufacturing process to ensure the purity and consistency of the sodium nitrate produced.

- The final product is tested for various parameters, including purity, chemical composition, and physical properties.

How can we handle your order?

step 1

We will communicate with you within 24 hours after you send an enquiry.

step 2

If you need sample testing, we will send samples within 5 days,≤50kg, Express delivery recommended, usually called as DDU service; delivery time 5-7 days. Door to door service.

step 3

If you need bulk goods after the sample test is qualified, we will ship the goods to the port and keep the samples within 6 days after the order is confirmed. Sea shipping recommended, usually called as FOB, CFR, or CIF service.delivery time 10-45 days. Port to port service.

step 4

After waiting for you to receive the goods, we will arrange professional staff to pay a return visit within 7 days.

REQUEST A QUOTE FOR MORE DETAILS

Sodium Nitrate Technical Data

| Name | Sodium nitrate |

| Molecular Formula | NNaO3 |

| Molar Mass | 84.99 |

| Density | 1.1g/mLat 25°C |

| Melting Point | 306 °C (dec.) (lit.) |

| Boling Point | 380 °C |

| Water Solubility | 900 g/L (20 ºC) |

| Solubility | H2O: 1M at20°C, clear, colorless |

| Appearance | Solid |

| Specific Gravity | 2.261 |

| Color | White or colorless |

| Odor | Odorless |

| Merck | 148647 |

| PH | 5.5-8.0 (50g/l, H2O, 20℃) |

| Storage Condition | Store at RT. |

| Stability | Stable. Strong oxidizer – may ignite flammable material. Incompatible with cyanides, combustible material, strong reducing agents, aluminium. |

| Sensitive | Hygroscopic |

| Physical and Chemical Properties | Properties colorless three-party crystal or rhomboid crystal or white fine crystal or powder. Odorless, salty, slightly bitter. melting point 306.8 ℃ relative density 2.261 solubility soluble in water and liquid ammonia, soluble in ethanol, methanol, slightly soluble in glycerol and acetone. |

Qualifications and Documents of Sodium Nitrate

Environment and Health

Environmental Impact

In the environment, sodium nitrate can contribute to nutrient pollution if not managed properly, particularly in agricultural runoff. However, in controlled amounts, it is an essential nutrient for plant growth, improving crop yields and soil fertility.

Handling and Storage

When handling sodium nitrate, standard safety measures should be observed. It should be stored in a cool, dry place, away from combustible materials. While it is not flammable, it can accelerate the burning of surrounding combustible materials due to its oxidizing nature.

Health Implications

Sodium nitrate is generally safe when handled with proper precautions. Direct contact can cause skin and eye irritation, and ingestion in large amounts can be harmful. Therefore, personal protective equipment such as gloves and safety glasses is recommended during handling.

Regulatory Compliance

Regulatory bodies have set guidelines for safely using and handling sodium nitrate to minimize occupational and environmental risks. Companies must comply with these regulations, ensuring that safety data sheets are accessible and employees are trained to manage the substance safely.

Advantages of the Chinese Sodium Nitrate Market

The global market for sodium nitrate, a versatile chemical compound with wide-ranging applications, has been experiencing significant growth. China, in particular, has emerged as a critical player in this market, offering unique advantages that make it an attractive hub for sodium nitrate production and export. This article explores the strengths and competitive edges of the Chinese sodium nitrate market.

1. Robust Manufacturing Infrastructure

China’s industrial growth over the past few decades has led to developing a strong manufacturing sector, particularly in chemicals. This robust infrastructure is a crucial advantage, allowing for large-scale production of sodium nitrate. The availability of advanced manufacturing facilities equipped with the latest technology ensures high efficiency and productivity in sodium nitrate production.

2. Abundant Raw Material Supply

China’s vast natural resources provide a steady supply of raw materials for sodium nitrate production. This abundance ensures a consistent and reliable supply chain, reducing the risks of shortages and price volatility. The availability of raw materials domestically also helps keep production costs lower.

3. Cost-Effectiveness

One of the most significant advantages of the Chinese market is its cost-effectiveness. The combination of lower labor costs, efficient production methods, and a streamlined supply chain allows Chinese manufacturers to offer sodium nitrate at competitive prices. This cost advantage makes Chinese sodium nitrate particularly appealing in the global market, especially for bulk and industrial buyers.

4. Strategic Global Trade Position

China’s strategic position in global trade, with its expansive shipping and logistics network, makes it an ideal location for exporting sodium nitrate. The country’s well-established maritime and land routes facilitate smooth and efficient transportation of sodium nitrate to various parts of the world, enhancing its accessibility to international markets.

5. Innovation and Research Development

Intense research and development initiatives back the Chinese chemical industry. Continuous innovation in production techniques and a focus on developing environmentally friendly and sustainable methods contribute to the advancement of the sodium nitrate market. These innovations help improve the product’s quality while adhering to international safety and environmental standards.

6. Government Support and Regulations

The Chinese government’s supportive policies towards the chemical industry significantly influence the market’s growth. Incentives for manufacturing, export subsidies, and favorable trade policies create a conducive environment for the sodium nitrate industry. Moreover, stringent regulations ensure that production meets global quality and safety standards, boosting the confidence of international buyers.

7. Diversified Application Sectors

China’s diverse industrial sectors, from agriculture to pharmaceuticals and manufacturing, provide a broad domestic market for sodium nitrates. The internal demand from these varied sectors ensures a steady market for sodium nitrate, fostering overall market stability and growth.

8. Global Demand Alignment

Finally, China’sChina’s sodium nitrate production aligns well with the global demand trends. With the increasing use of sodium nitrate in various industries such as agriculture (as fertilizer), food preservation, and manufacturing, China is well-positioned to meet this growing demand domestically and internationally.

Conclusion

The Chinese sodium nitrate market presents numerous advantages, from cost-effectiveness and robust infrastructure to innovation and strategic global positioning. These factors collectively contribute to China’s growing prominence in the worldwide sodium nitrate market, making it a key player in fulfilling the world’s sodium nitrate needs. As global demand continues to rise, China’s role in this market is expected to become even more significant, offering opportunities for both domestic and international stakeholders.

Sodium Nitrate FAQs

For purchasing Sodium Nitrate, buyers must have appropriate qualifications to handle hazardous chemicals and adhere to regional regulations. Different regions have specific rules governing the sale and use of dangerous substances, making compliance with these regulations essential. Buyers should be familiar with local and international hazardous chemical purchases and usage laws.

Sodium Nitrate is utilized to enhance the efficiency of manufacturing processes, serve as a preservative in the food industry, and act as a vital oxidizing agent in the production of explosives and fertilizers.

High-quality Sodium Nitrate, characterized by high purity levels, ensures consistency and reliability in industrial processes, leading to superior-end products and safer food preservation practices.

Yes, when used in regulated amounts, Sodium Nitrate is safe and approved as a preservative in food processing to prevent bacterial growth and preserve freshness.

High-quality sodium nitrate can be purchased directly from Eapearl Chemicals through our B2B ordering process, designed for efficiency and reliability.

To place a bulk order, contact our sales team via the contact form on our website or call us directly. Our streamlined ordering process ensures a smooth transaction.

Eapearl Chemicals stands out due to our commitment to quality, competitive pricing, reliable supply chain, global reach, and customer-centric approach, ensuring you get the best value and service.

Sodium Nitrate provided by Eapearl Chemicals has a distinct chemical composition and use case compared to Sodium Nitrite. Our Sodium Nitrate is designed for industrial applications requiring specific oxidizing properties and stability.

Sodium Nitrate is considered safe for use in various industries when handled according to safety guidelines. Eapearl Chemicals ensures that all our products meet safety standards to mitigate health risks.

We adhere to strict safety protocols, including regular quality checks, providing clear handling instructions, and ensuring compliance with all regulatory standards to ensure the safety of our Sodium Nitrate.